A kind of vanadium-carbon composite combustion catalyst for propellant and preparation method thereof

A technology for burning catalysts and complexes, which is used in offensive equipment, non-explosive/non-thermal components, explosives, etc., to achieve the effects of high safety, environmentally friendly catalytic activity, and precisely adjustable loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

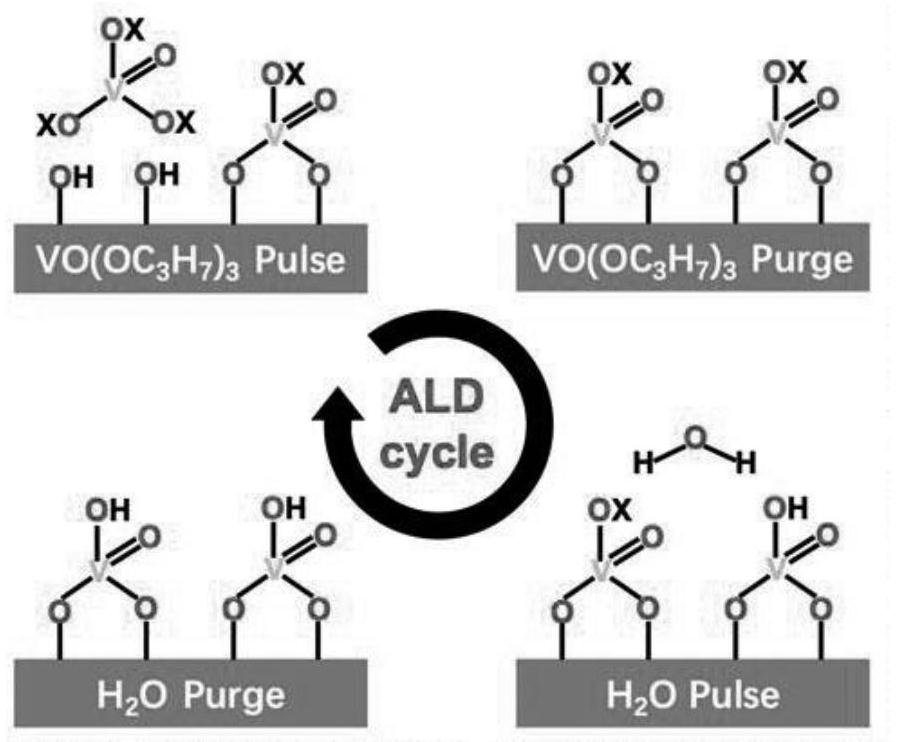

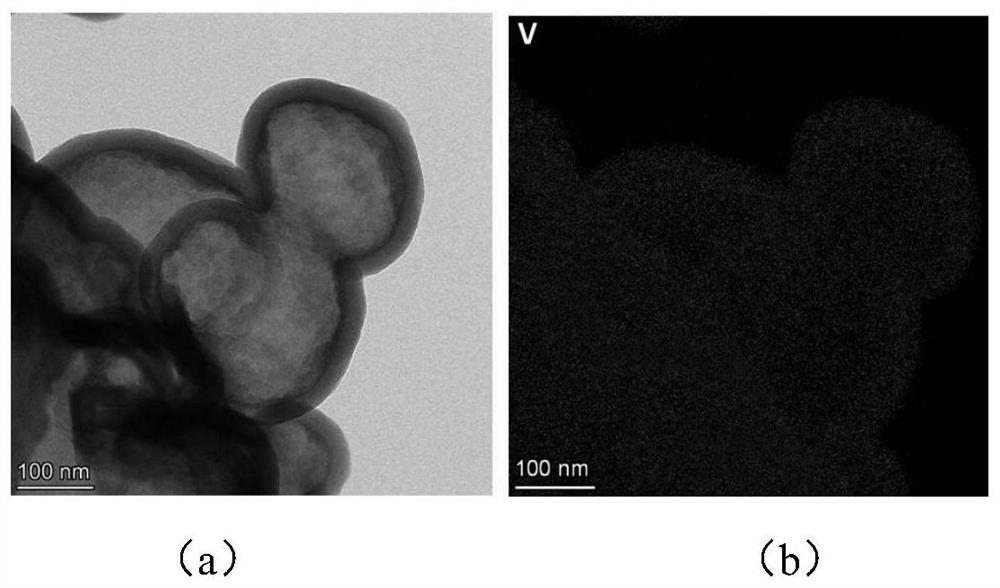

[0038] This embodiment proposes a vanadium-carbon composite combustion catalyst for propellants and a preparation method thereof. The carbon-based base material used is carbon airgel microspheres (CarbonAerogel Spheres, CAS). The preparation method specifically includes the following steps:

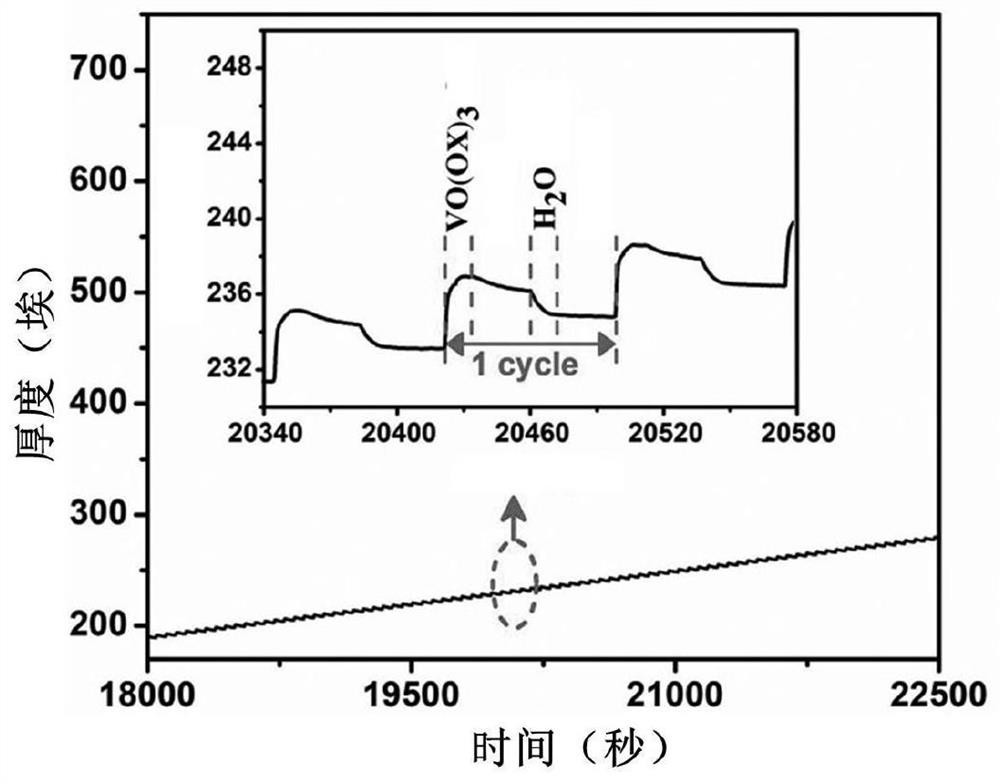

[0039] Step 1. Spread the carbon airgel microspheres in the reaction chamber of the atomic layer deposition equipment, install a quartz crystal microbalance at the outlet of the reaction chamber and seal the outlet;

[0040] Step 2, heating the atomic layer deposition reaction chamber and vanadyl triisopropoxy (VO(OC) respectively by an electric heating mantle 3 h 7 ) 3 ) hold the container so that its temperature is respectively at 150°C and 50°C;

[0041] Step 3. Nitrogen gas with a flow rate of 60 sccm is passed into the reaction chamber from the entrance of the reaction chamber of the atomic layer deposition equipment, and a mechanical vacuum pump is used to pump air at the outlet o...

Embodiment 2

[0055] This embodiment proposes a vanadium-carbon composite combustion catalyst for propellants and a preparation method thereof. The carbon-based base material used is reduced graphene (rGO). The preparation method specifically includes the following steps:

[0056] Step 1, tile the reduced graphene in the reaction chamber of the atomic layer deposition equipment;

[0057] Step 2. Heat the atomic layer deposition reaction chamber and the vanadyl acetylacetonate (VO(acac) 2 ) containers at temperatures of 300°C and 150°C, respectively;

[0058] Step 3. Nitrogen gas with a flow rate of 80 sccm is passed into the reaction chamber from the entrance of the reaction chamber of the atomic layer deposition equipment, and a mechanical vacuum pump is used to pump air at the outlet of the reaction chamber of the atomic layer deposition equipment, so that the vacuum degree in the reaction chamber is at 120Pa;

[0059] Step 4, the VO(acac) 2 Molecules are injected into the reaction cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com