A sorting system and process for plate-type customized furniture

A furniture and panel technology, applied in the field of panel customized furniture sorting systems, can solve the problems of low work efficiency and high error rate, and achieve the effects of improving material utilization, preventing warehouse explosion, and reducing sorting error rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

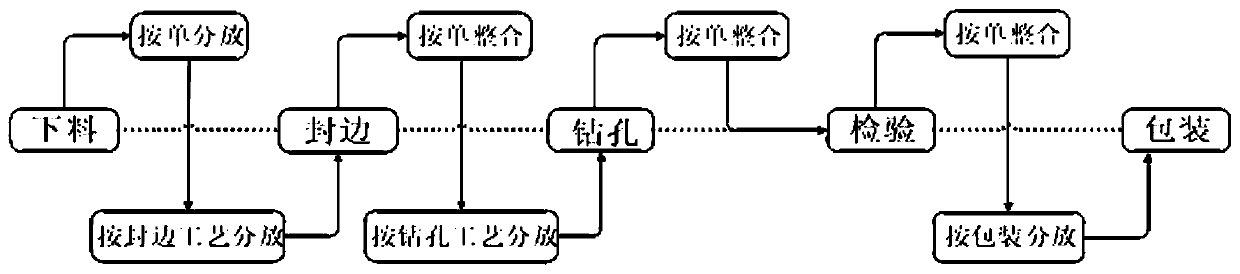

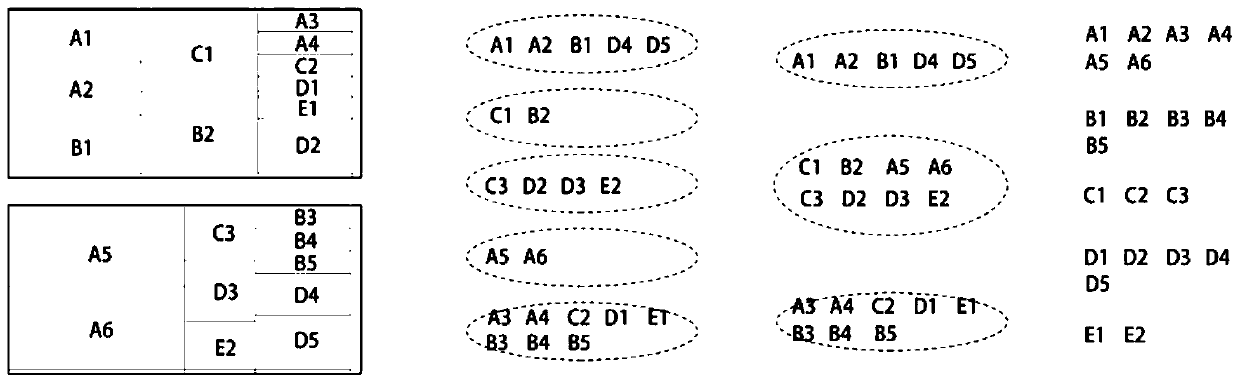

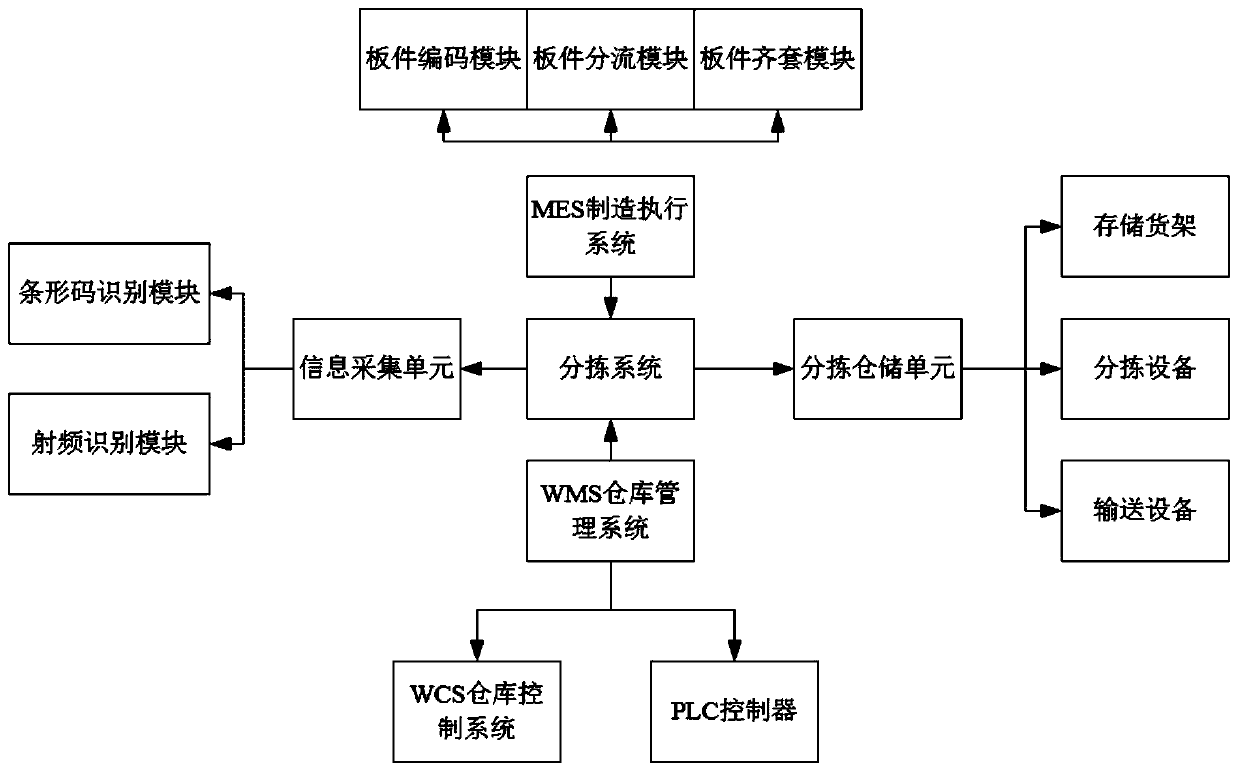

Method used

Image

Examples

Embodiment 1

[0060]A panel-type custom-made furniture company, first of all, according to the difference in the length of the panels, it is divided into small panels with a length between 300mm and 1000mm and large panels with a length greater than 1000mm, and correspondingly set up ring shelves 5 and vertical shelves 7, and designed Position size standard. Secondly, considering the storage capacity of the shelf, the storage capacity requirement of the ring shelf 5 is 580 pieces per batch, designed according to 3 layers per group, 20 positions on each layer, and a total of 6 groups. The storage capacity of a ring shelf 5 is 20×3×6, that is, 360 pieces. Therefore, the company plans to have two ring-shaped shelves with a storage capacity of 720 pieces to meet the company's existing and future production needs. The storage capacity requirement of the vertical shelf 7 is 220 pieces per batch. According to data calculations, more than 90% of the long pieces have a width of no more than 600mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com