Control system of bulk material conveying system in butt joint with environmental protection monitoring data

A control system and environmental monitoring technology, applied in the control system field of bulk material conveying system, can solve the problems of powder leakage, particle pollution, unenvironmental protection, etc., to solve the problem of poor monitoring timeliness, solve incomplete monitoring, and be beneficial to the environment protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

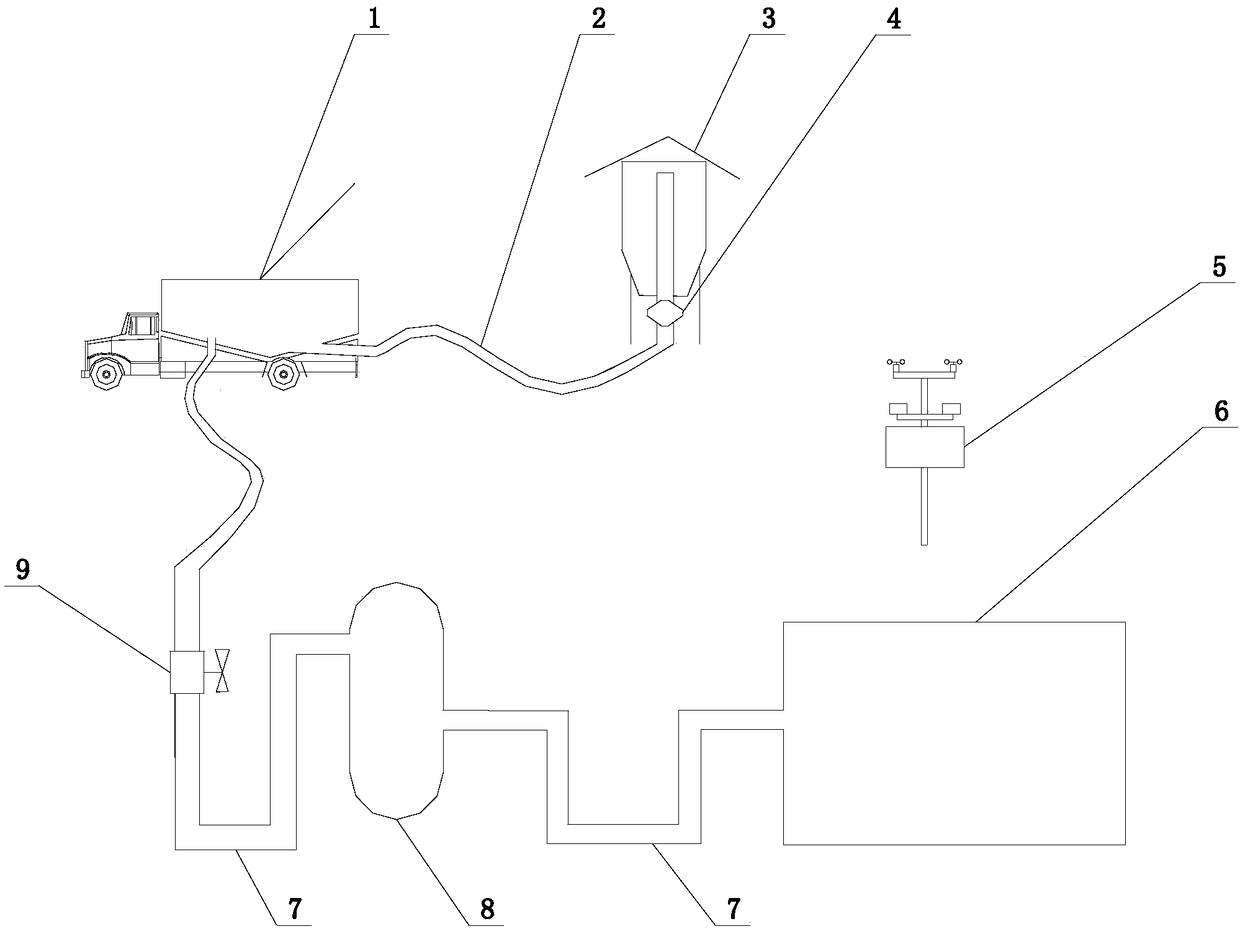

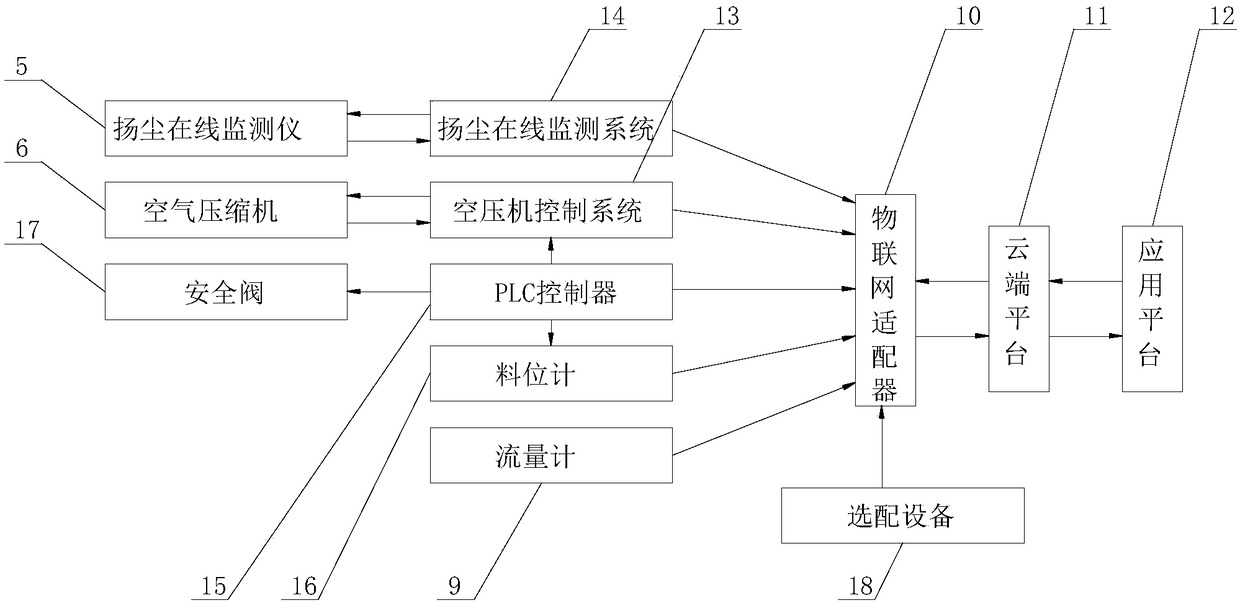

[0040] A control system of a bulk material conveying system connected with environmental monitoring data, including an Internet of Things adapter 10, a cloud platform 11, an application platform 12, an air compressor control system 13, an online dust monitoring system 14, a feed valve 4, and PLC control device 15; the Internet of Things adapter 10 is used to obtain the operating status data of the air compressor 6, the dust online monitor 5 and the process action valve in the bulk material conveying system, and upload the operating status data to the cloud platform 11; the PLC controller 15 Communicatively connected with the Internet of Things adapter 10, the PLC controller 15 is used to control the action of the process action valve in the air compressor control system 13 and the bulk material conveying system; the process action valve includes a feed valve installed at the feed port of the silo 3 4; the cloud platform 11 is connected to the Internet of Things adapter 10 throu...

Embodiment 2

[0043] A control system of a bulk material conveying system connected with environmental monitoring data, including an Internet of Things adapter 10, a cloud platform 11, an application platform 12, an air compressor control system 13, an online dust monitoring system 14, a feed valve 4, and PLC control device 15; the Internet of Things adapter 10 is used to obtain the operating status data of the air compressor 6, the dust online monitor 5 and the process action valve in the bulk material conveying system, and upload the operating status data to the cloud platform 11; the PLC controller 15 Communicatively connected with the Internet of Things adapter 10, the PLC controller 15 is used to control the action of the process action valve in the air compressor control system 13 and the bulk material conveying system; the process action valve includes a feed valve installed at the feed port of the silo 3 4; the cloud platform 11 is connected to the Internet of Things adapter 10 throu...

Embodiment 3

[0057] A control system of a bulk material conveying system connected with environmental monitoring data, including an Internet of Things adapter 10, a cloud platform 11, an application platform 12, an air compressor control system 13, an online dust monitoring system 14, a feed valve 4, and PLC control device 15; the Internet of Things adapter 10 is used to obtain the operating status data of the air compressor 6, the dust online monitor 5 and the process action valve in the bulk material conveying system, and upload the operating status data to the cloud platform 11; the PLC controller 15 Communicatively connected with the Internet of Things adapter 10, the PLC controller 15 is used to control the action of the process action valve in the air compressor control system 13 and the bulk material conveying system; the process action valve includes a feed valve installed at the feed port of the silo 3 4; the cloud platform 11 is connected to the Internet of Things adapter 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com