Powder tank and material level control method thereof

A technology of powder tanks and powder materials, which is applied in the field of powder tanks of mixing stations, can solve the problems of inability to accurately control the amount of powder materials, and achieve the effects of avoiding insufficient materials, prolonging service life, and avoiding production stoppage due to lack of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

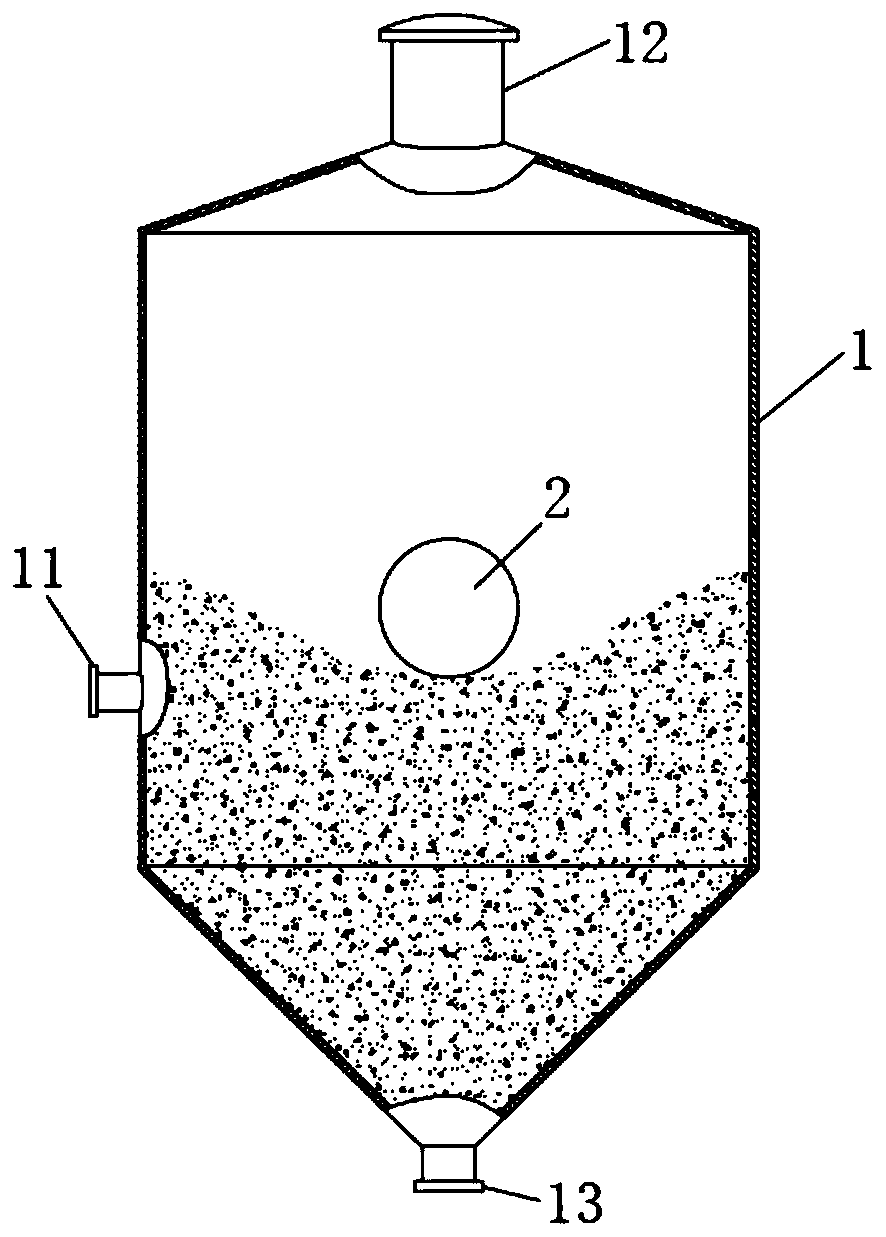

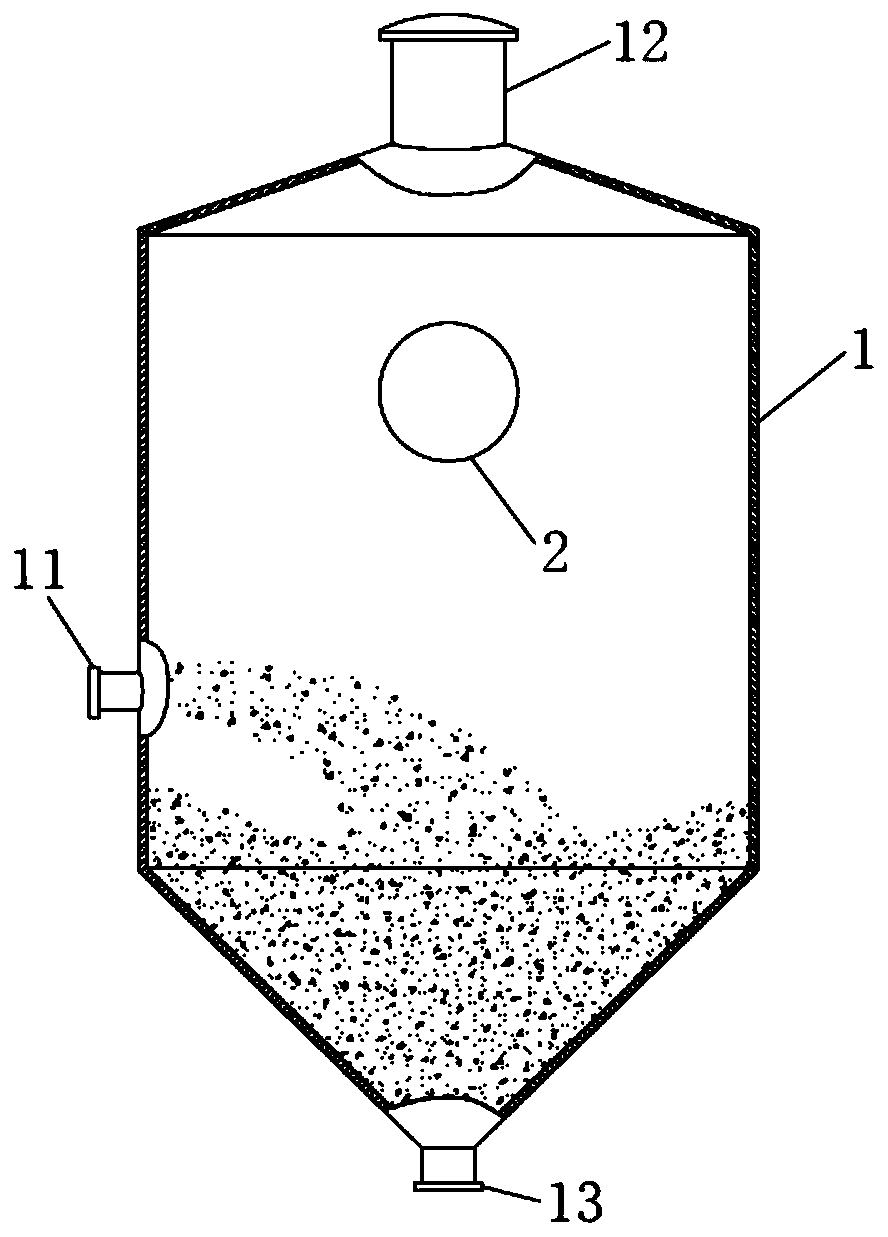

[0039] Such as figure 1 with figure 2 As shown in , a powder tank in this embodiment includes a powder tank body 1, a feed port 11 is provided at the waist, a discharge port 13 is provided at the bottom, and a dust collector 12 is provided at the top; it also includes a floating ball The material level device 2 floats on the surface of the powder in the powder tank body 1 to collect and feed back the material level of the powder in the powder tank body 1 in real time. The ratio of the gravity of the float level device 2 to the buoyancy of the air is 1:0.7-0.9, which ensures that it can float when it is impacted by the injection air flow, so as to avoid being submerged by the injected powder; Finally, because its own gravity is greater than the received buoyancy, it can ensure that it slowly falls to the surface of the powder, thereby collecting the material level height of the powder in the powder tank body 1. In this embodiment, the ratio of the gravity of the float level ...

Embodiment 2

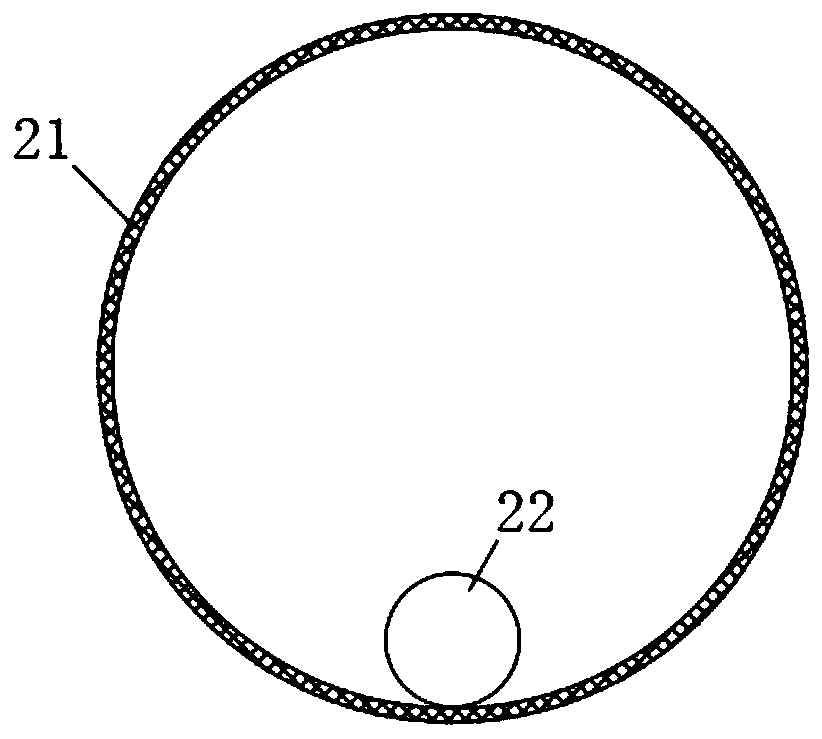

[0048] The powder tank in the present embodiment is basically the same as in Embodiment 1, the differences and improvements are as follows: Figure 4 As shown in , the side wall of the sphere 21 includes an airtight layer 211 , a puncture-resistant layer 212 and a wear-resistant layer 213 from inside to outside. The airtight layer 211 is arranged on the innermost layer of the sphere 21 to form a seal inside the sphere 21 to prevent the light gas inside the sphere 21 from leaking, and the innermost layer will not touch hard object, and then will not be worn and punctured, and the sealing performance is always better after long-term use; The airtight layer 211 is used to prevent the sphere 21 from being pierced after hitting a hard object; the wear-resistant layer 213 is arranged outside the puncture-resistant layer 212 to increase the wear resistance of the surface of the sphere 21 , to prevent the ball 21 from being worn out after long-term use.

[0049] Such as Figure 4 A...

Embodiment 3

[0053] The powder tank in the present embodiment, basic structure is the same as embodiment 2, difference and improvement are, as Figure 4 As shown in , the sphere 21 is provided with a gas injection nozzle 23 for filling the sphere 21 with light gas.

[0054] After long-term use, the light gas in the sphere 21 will permeate out of the sphere 21, causing the float level device 2 to fail because it is not easy to float, so it is necessary to replace the float level device 2 regularly, resulting in Waste of cost.

[0055] In this embodiment, by setting the gas injection nozzle 23 on the sphere 21, when the float level gauge 2 fails to float, take out the float level gauge 2 from the powder tank body 1 , and then supplement the light gas into the sphere 21 through the gas injection nozzle 23, so that the float level device 2 can be used repeatedly and the replacement cost can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com