Composite aluminum-plastic panel curved surface gluing machine

A composite aluminum and gluing machine technology, applied in the field of building materials, can solve the problems that temperature adjustment cannot be independently set, the surface of aluminum-plastic panels is damaged, and the product yield is affected, so as to achieve temperature balance, improve stability, and improve heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

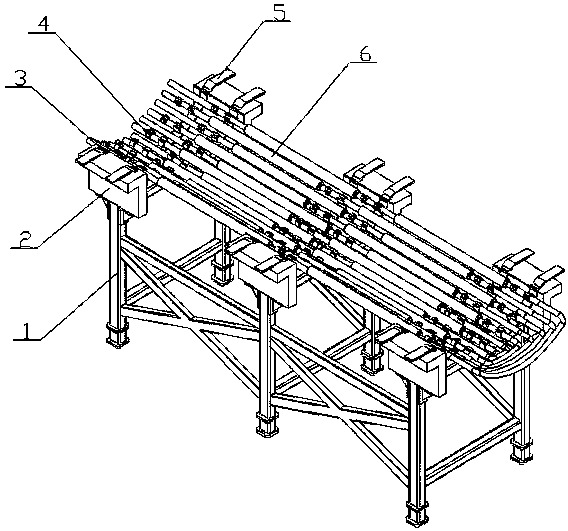

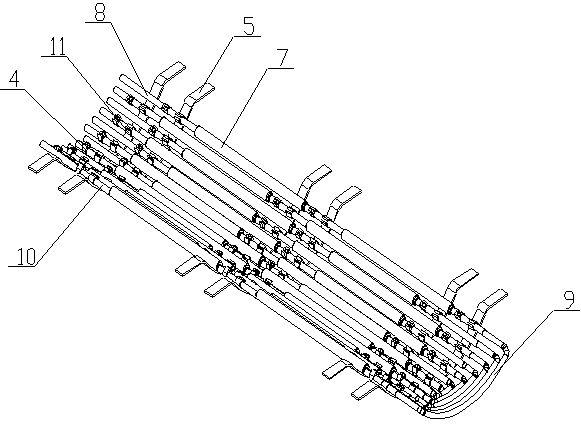

[0033] A composite aluminum-plastic plate curved surface gluing machine of the present invention is realized in this way, and is composed of a main body bracket (1), a heating tube group (6) and a transmission mechanism, and the upper end surface of the main body bracket (1) is a concave arc-shaped bearing The supporting surface, the heating tube group (6) is placed on the arc-shaped supporting surface of the upper end surface of the main body support (1), and the transmission mechanism is detachably placed on the heating tube group (6).

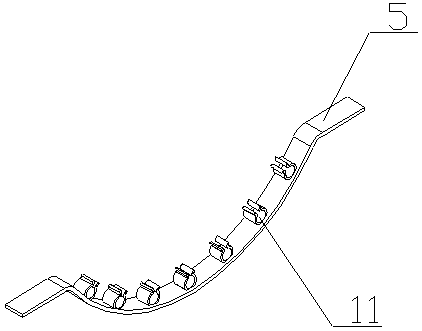

[0034] The main bracket (1) is composed of a bracket body, a bracket (2), a guide groove (3), a support plate (5) and an installation buckle (11). There are multiple groups of brackets (2) equidistant from the bracket body. The frame body is composed of steel profiles, a set of brackets (2) includes two oppositely distributed brackets (2), and a guide groove (3) is opened on the inner side of the bracket (2); the guide groove (3) is an obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com