A flexible printing high-strength energy-saving and consumption-reducing corrugated box

A flexible printing and corrugated box technology, applied in rigid containers, container handles, transportation and packaging, etc., can solve the problems of insufficient overall strength of corrugated boxes, poor shockproof and high temperature resistance, poor compression resistance, etc., to facilitate unified transportation management , Improve the compression resistance and enhance the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

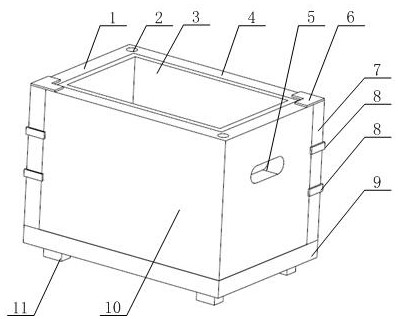

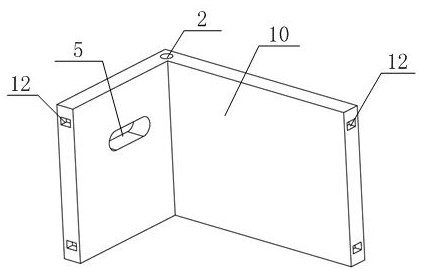

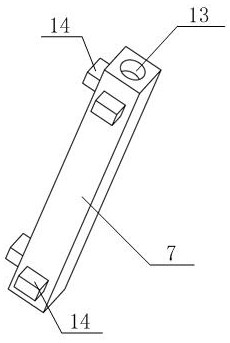

[0037] Such as Figure 1~Figure 6 as shown,

[0038]A flexible printing high-strength energy-saving and consumption-reducing corrugated box, comprising a corrugated box body 1 and a base 9 connected to the bottom, the corrugated box body 1 includes an inner box body 3 and an outer box body 4, and the inner box body 3 is detachably arranged on the outside Inside the box body 4, a corrugated cardboard layer is arranged between the inner box body 3 and the outer box body 4, and the outer box body 4 is composed of two L-shaped connecting plates 10 connected to each other, and two adjacent L-shaped connecting plates 10 They are all connected by plugging columns 7, the top and bottom of the intersection of the L-shaped connecting plate 10 are provided with first connecting holes 2, and the two sides of the L-shaped connecting plate 10 are provided with second card slots near the top and bottom. 12. The top and bottom of the plug-in column 7 are provided with a second connection hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com