Surfactant for development of low-permeability oil reservoir and preparation method of surfactant

A low-permeability, catalyst technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problems of poor stability, adsorption, precipitation, chromatographic separation, etc., and achieve the effects of low production cost, good dissolution, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

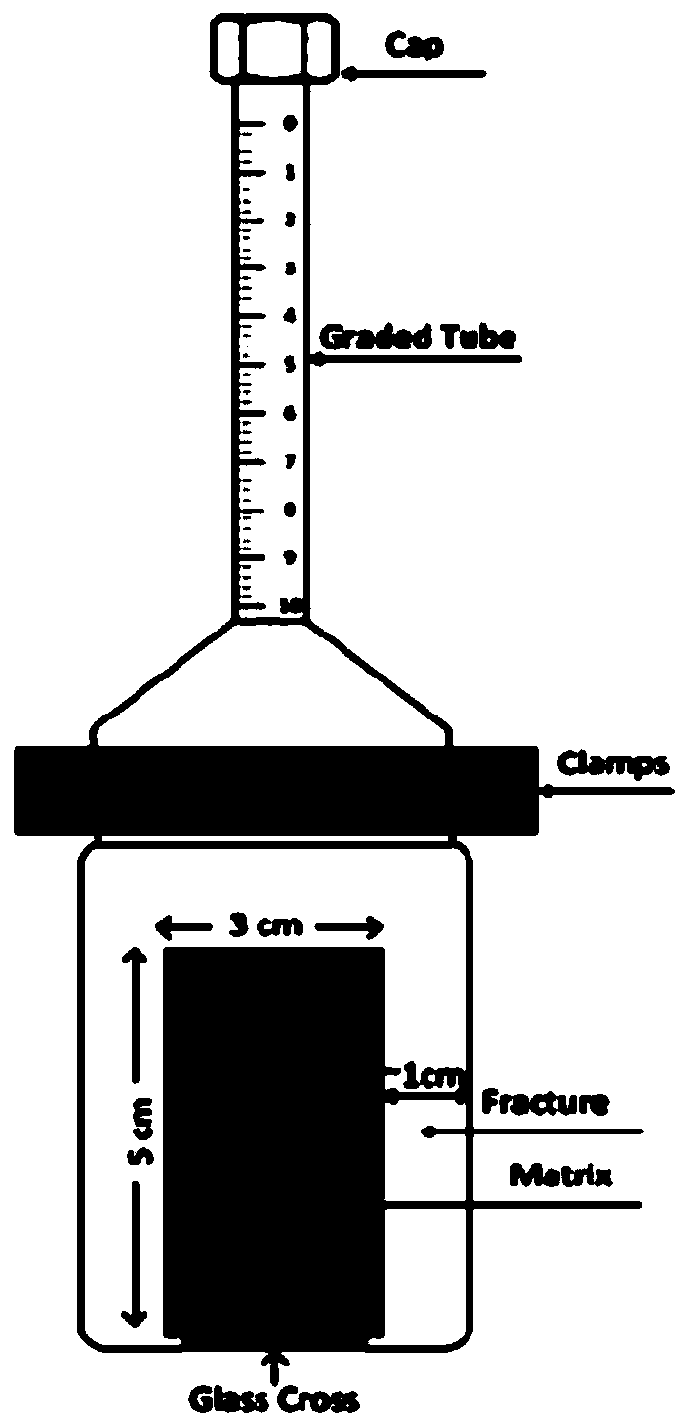

Image

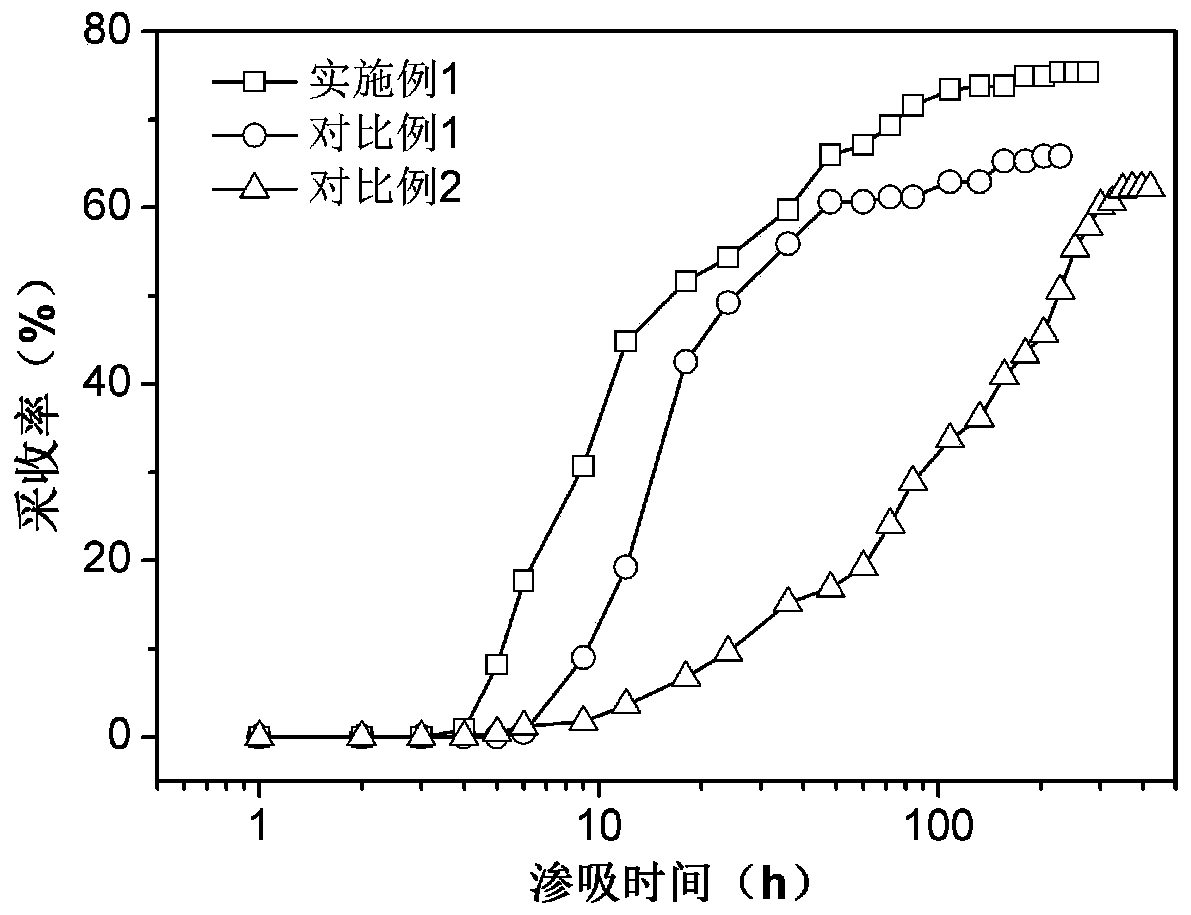

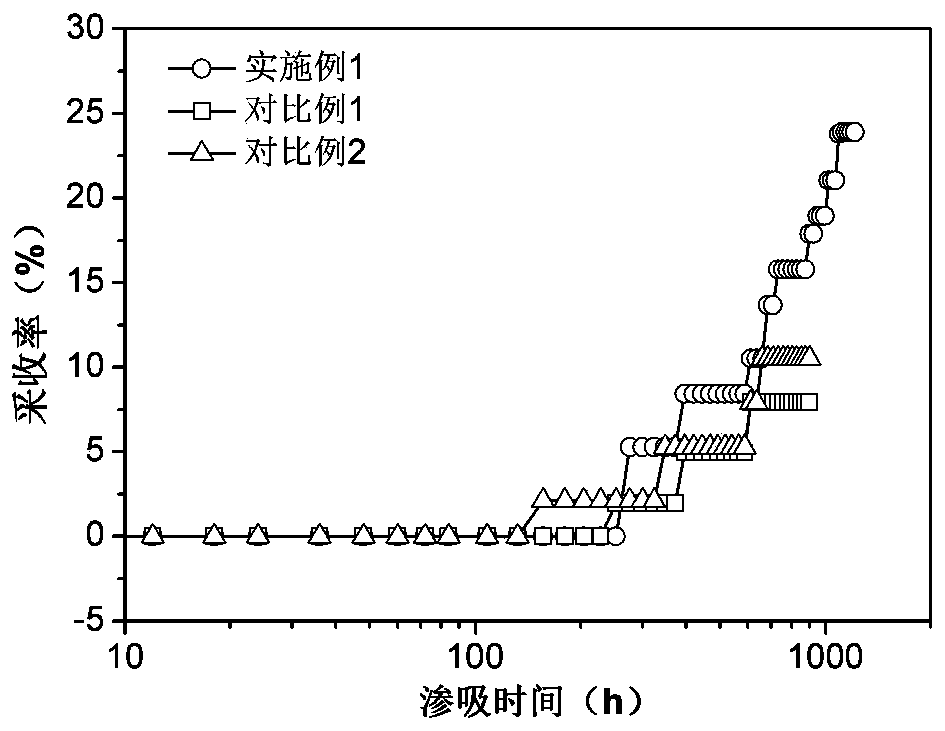

Examples

Embodiment 1

[0059] (1) Preparation of amidation product

[0060] Add 120g palmitic acid, 100g 1-(4-hydroxyphenyl)piperazine, and 0.9g sodium fluoride into a four-necked glass bottle equipped with a stirrer, nitrogen pipe, drying pipe and thermometer, heat up and stir until all The raw materials were dissolved, and nitrogen gas was introduced for 20 minutes, the reaction temperature was controlled at 170°C, the reaction was carried out for 12 hours, and the volatile components were removed by distillation under reduced pressure at 180°C to obtain the amidation product shown in formula IV;

[0061]

[0062] In the formula IV, R is C 15 h 31 ;

[0063] (2) Preparation of polyoxyethylene segment product shown in formula III

[0064] Add 150g of the amidation product and 0.6g of potassium hydroxide into the autoclave, seal it and vacuumize to -0.1MPa while raising the temperature, continue vacuuming to 100°C, add 100g of ethylene oxide, control the reaction temperature at 120°C, and the ...

Embodiment 2

[0078] As described in Example 1, the difference is that the organic acid is capric acid in the step (1), and the addition amount is 135g.

Embodiment 3

[0080] As described in Example 1, the difference is that the organic acid in step (1) is behenic acid.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap