Peak shaving method of thermal power generating unit

A technology for thermal power units and peak regulation, which is applied in steam generation, lighting and heating equipment, control systems, etc., and can solve problems such as affecting the normal power generation of power plants, tripping of generator sets, and difficulty in adapting to peak regulation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that the embodiments of the present invention and the features of the embodiments can be combined with each other if there is no conflict.

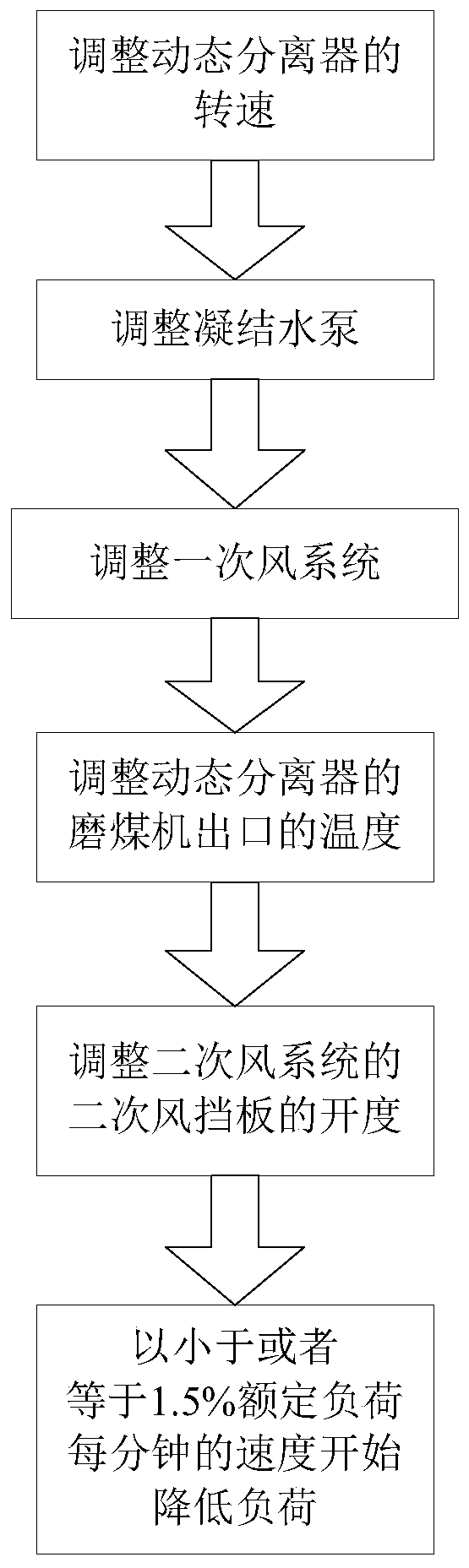

[0041] The present invention provides a method for peak shaving of a thermal power unit. The thermal power unit includes a boiler, a boiler denitration system, a steam turbine, and a steam and water system connecting the boiler and the steam turbine. The boiler includes multiple coal mills, each The coal mill includes a dynamic separator, a burner, and an air supply system, and the air supply system includes a primary air system and a secondary air system, where, see figure 1 ,

[0042] The peak shaving method includes:

[0043] The first step is to adjust the dynamic separator of the coal mill so that the fineness of pulverized coal is less than or equal to the predetermined value of fineness of pulverized coal, so as to ensure that the pulverized coal can be fully and stably burned, and to avoid combustion caused by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com