Bottom-layer burner

A burner and underlying technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve problems affecting the combustion effect of the combustion system, and achieve the effects of ensuring environmental sanitation and safety, sufficient and effective combustion, and removal of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. One or more embodiments of the present invention are exemplarily shown in the drawings, so as to make the understanding of the technical solutions disclosed in the present invention more accurate and thorough. However, it should be understood that the present invention can be implemented in various forms and is not limited to the embodiments described below.

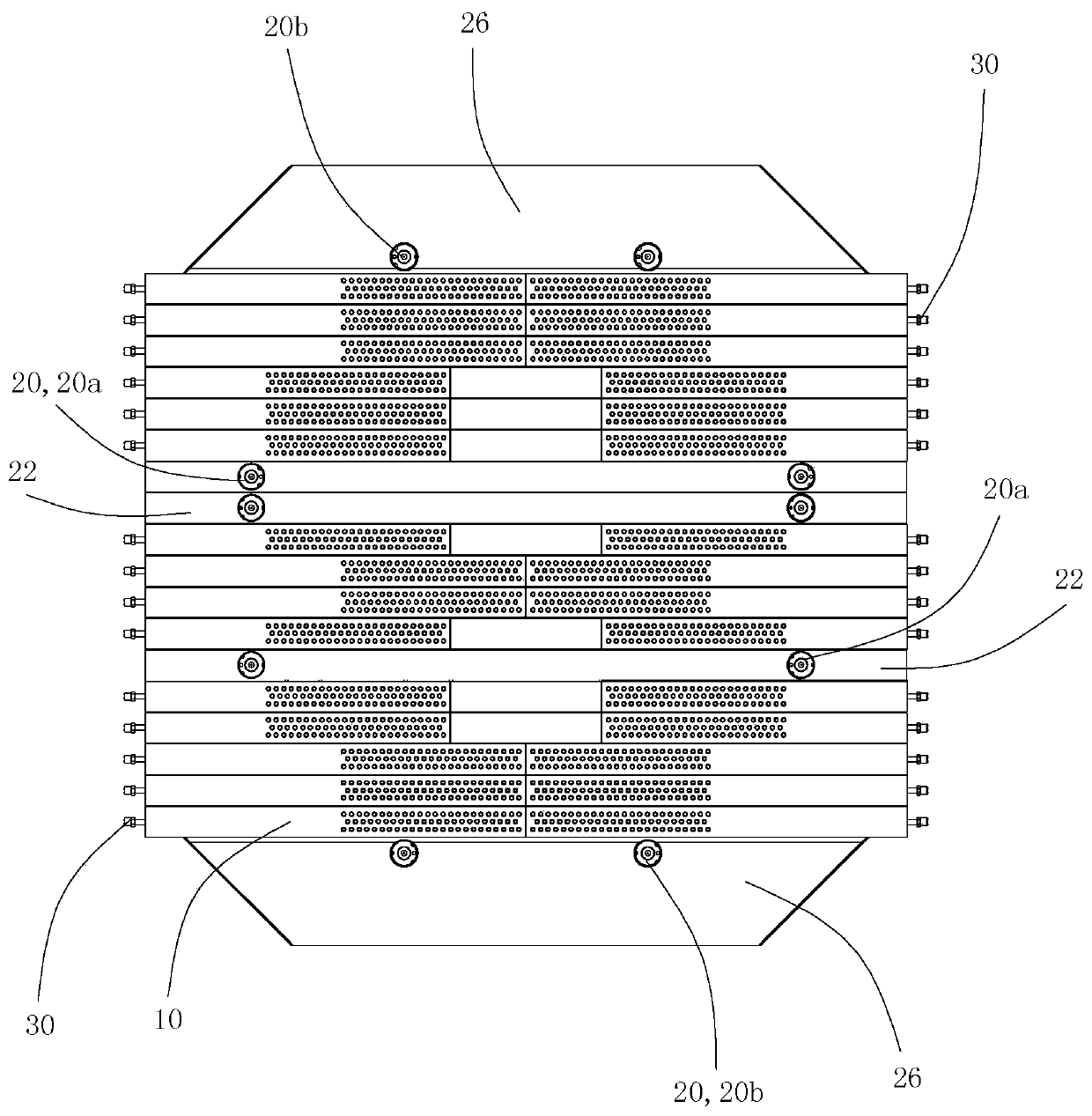

[0021] Such as figure 1 As shown, the bottom burner 10 of the present invention includes a burner 10 , an pilot light 20 , and a nozzle 30 .

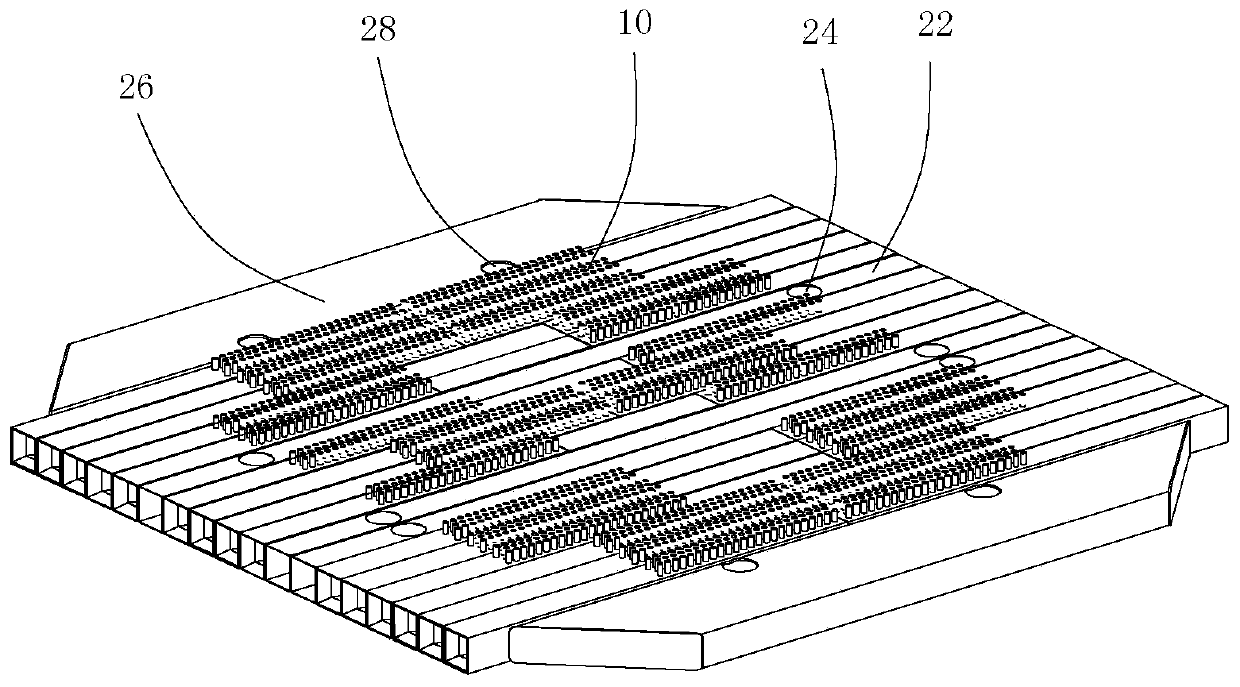

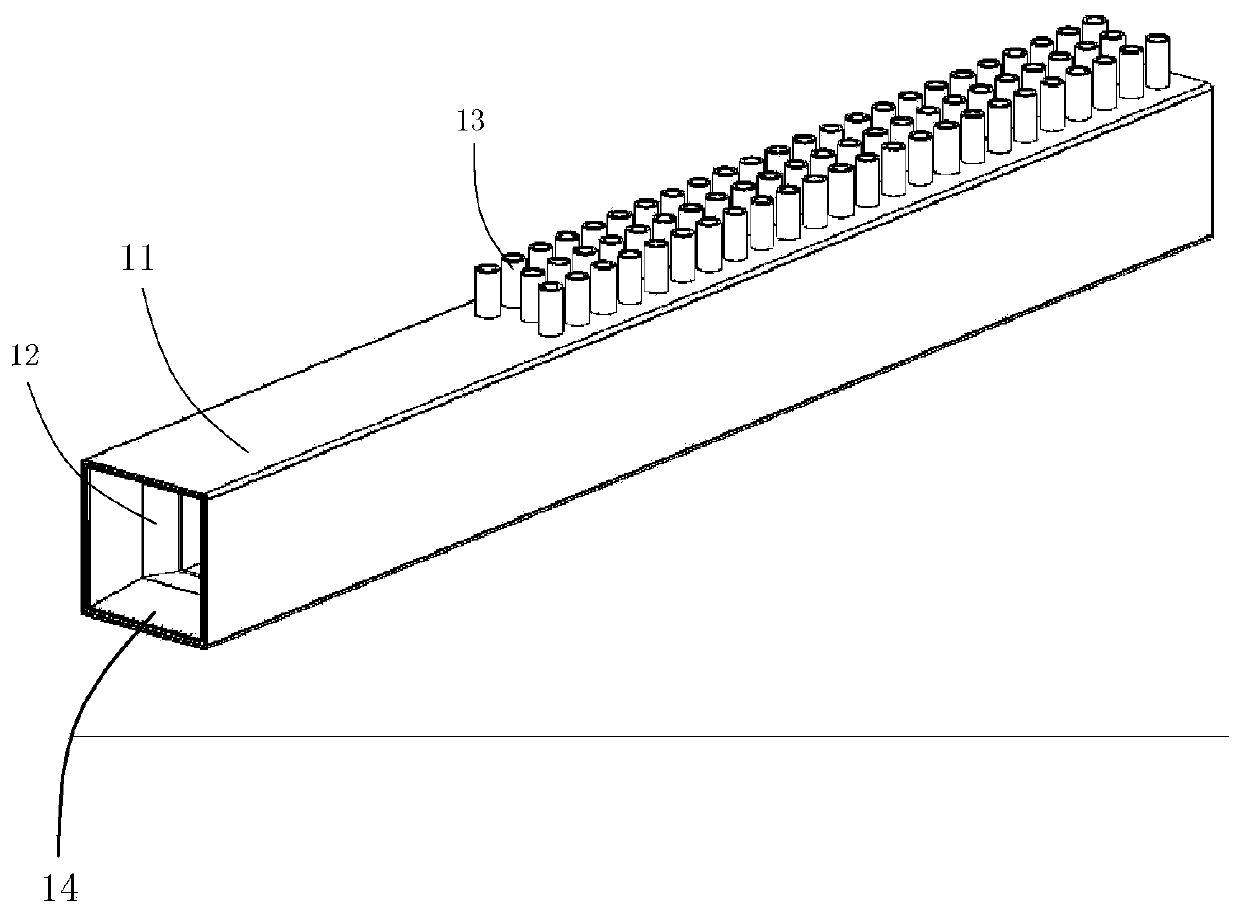

[0022] There are multiple burners 10 arranged in an array. Please also see figure 2 and image 3 , the burners 10 are all venturi burners, and each burner 10 includes a casing 11 , a venturi pipe 12 formed in the casing 11 , and a combustion head 13 formed on the casing 11 . The casing 11 is a longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com