A test method for field of view splicing accuracy of large field of view area array devices

A field of view splicing and precision testing technology, applied in the field of aerospace optical remote sensors, can solve the problems of low installation and adjustment accuracy, difficult engineering realization, etc., and achieve the effect of strong operability and small environmental interference factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

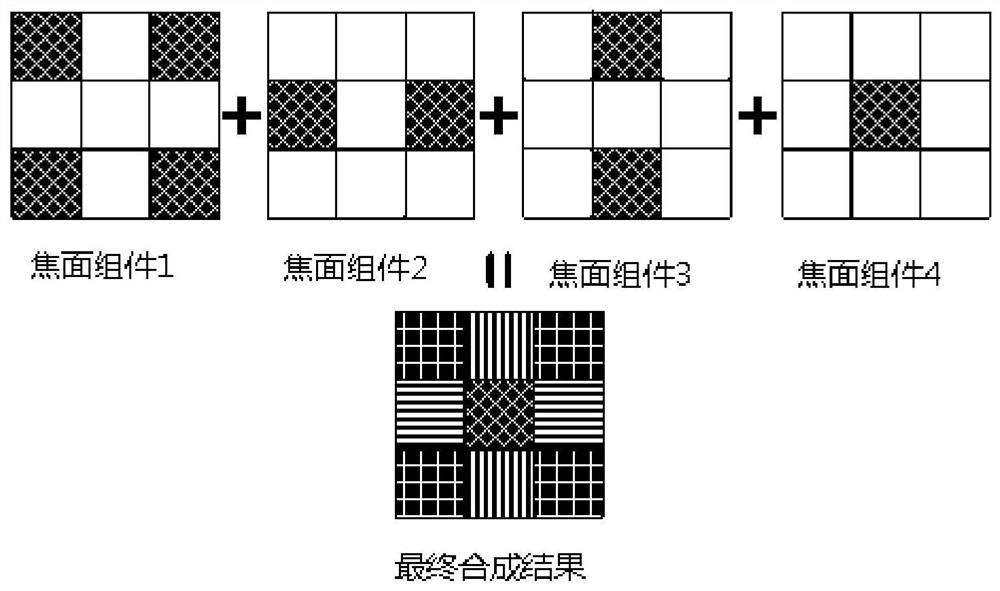

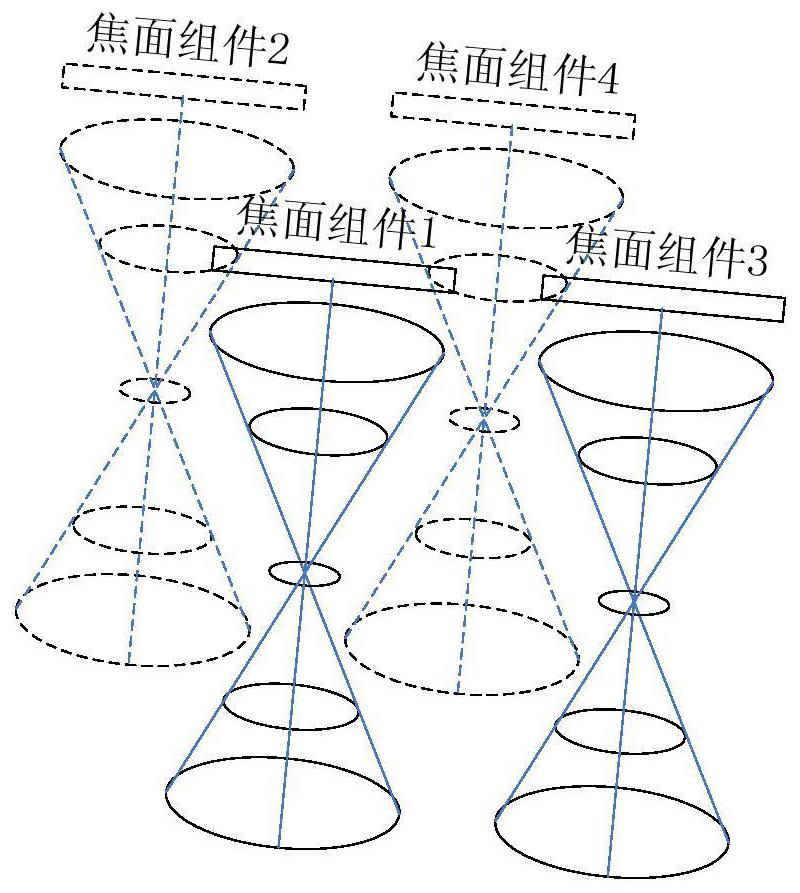

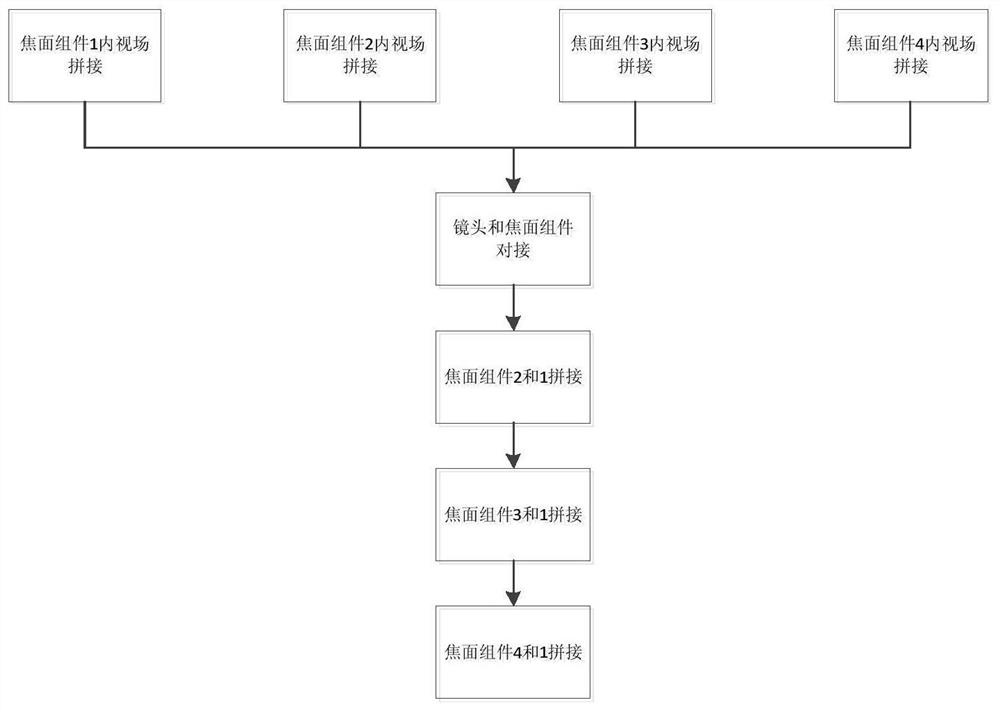

[0052] Set N = 4, M 1 = 4, M 2 = M 3 = 2, M 4 =1. The camera parameters that need field of view stitching are: the entire camera uses 4 sets of optical lenses, and these 4 sets of optical lenses correspond to different numbers of CMOS area array devices with a pixel number of 10k×10k, namely 4, 2, and 2 , 1. Through the mixed stitching method of the inner and outer fields of view, the resulting images are superimposed to achieve 3×3 CMOS digital back stitching, reaching a large format with a total number of pixels of about 30k×30k. The stitching process and the stitching are shown as follows figure 1 shown. The camera optical system and focal plane are composed of figure 2 shown.

[0053] The size of the focal plane of the four groups of lenses is as follows: figure 2 As shown (focal plane 2 and focal plane 3 correspond to the same optical system). In order to ensure the consistency of the optical system as much as possible, the panchromatic optical system correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com