Novel man-machine comfort verification mechanism

A comfort, human-machine technology, applied in the field of new human-machine comfort verification institutions, can solve the problems of high cost and inaccurate results, and achieve accurate test results, comprehensive test data, and real and reliable test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

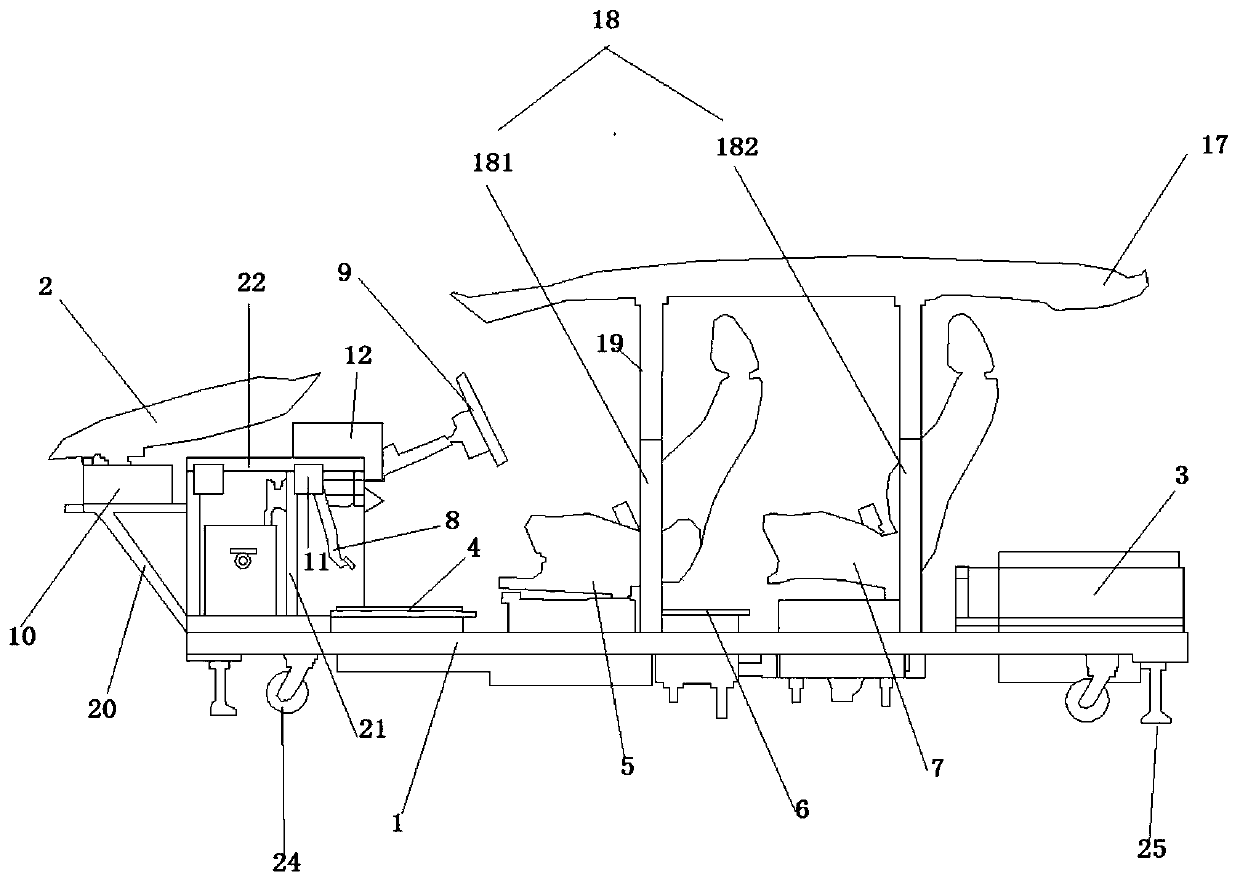

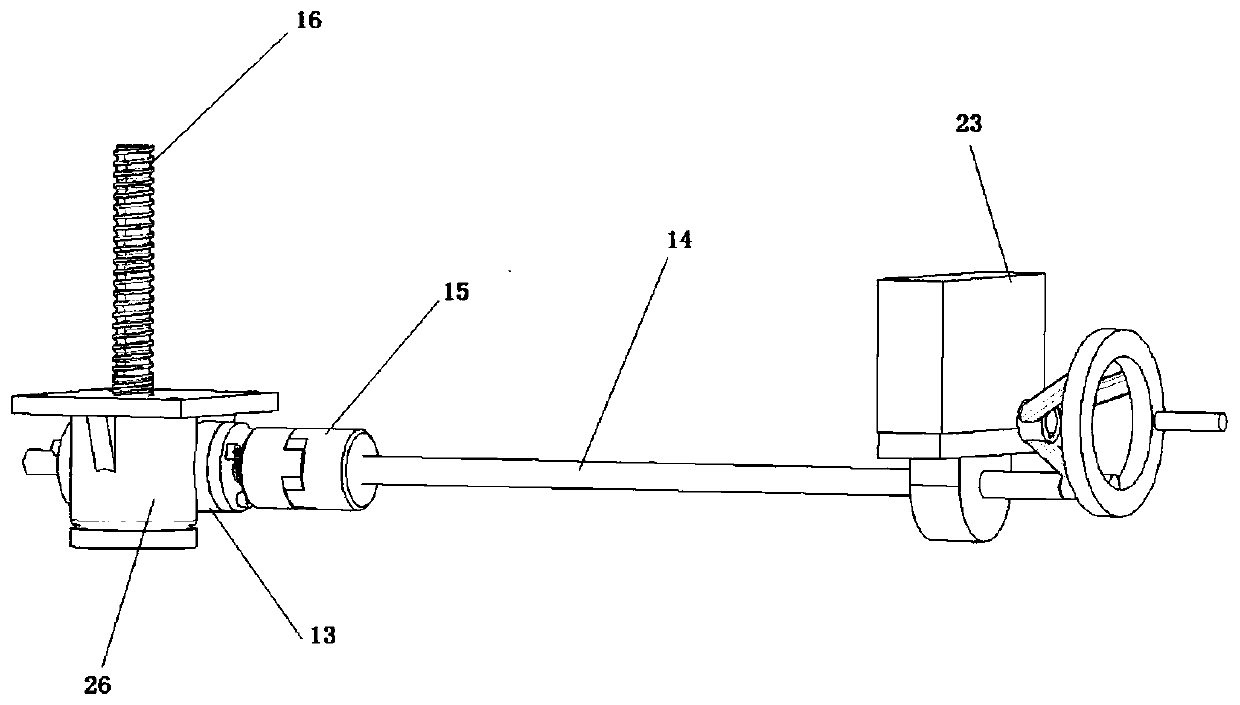

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0033] like figure 1 As shown, the new human-machine comfort verification mechanism includes a base plate 1, an engine compartment cover 2 arranged at the front end of the base plate, a luggage compartment 3 arranged at the rear end of the base plate, and a front floor is arranged in sequence between the engine compartment cover 2 and the luggage compartment 3 adjuster, front row seat adjuster, rear row floor adjuster and rear row seat adjuster and these structures all contain mounting holes adapted to the bottom plate, front row floor 4, front row seat 5, rear row floor 6 and rear seat 7 can move horizontally on the front floor adjuster, front seat adjuster, rear floor adjuster and rear seat adjuster respectively;

[0034] A pedal 8 is also arranged above the front floor, and a steering wheel 9 is arranged between the pedal 8 and the front sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com