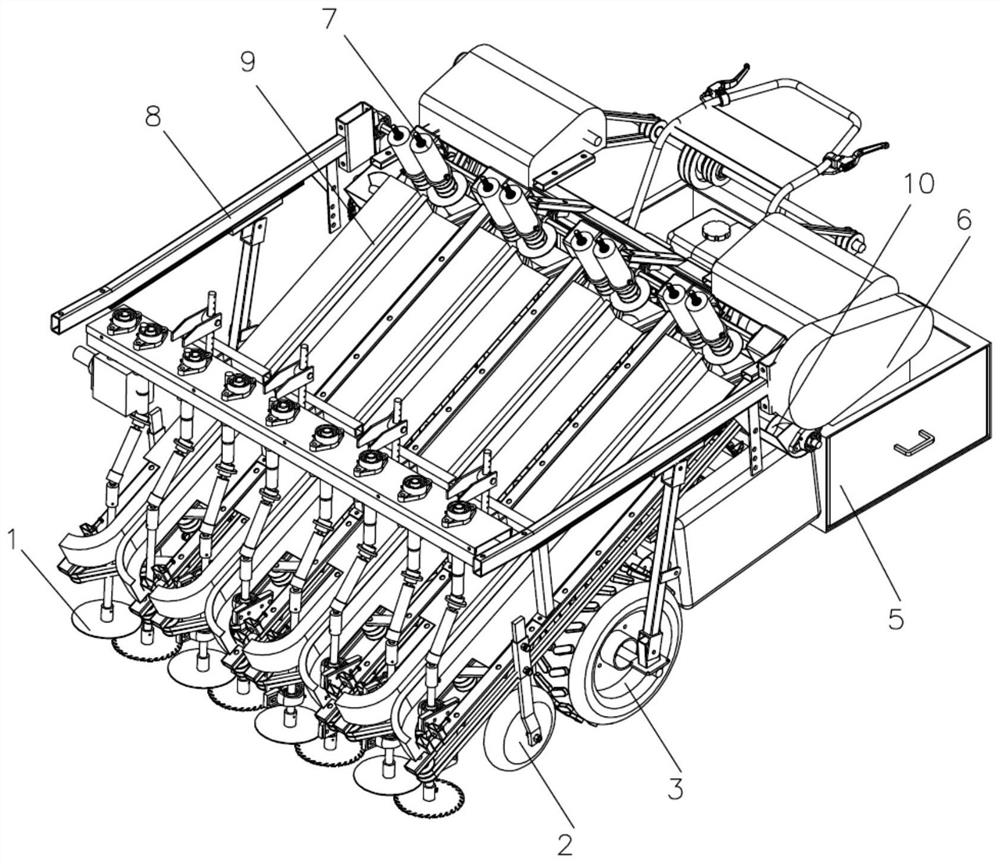

Self-adaptive header of a leaf vegetable combine harvester

A combine harvester and self-adaptive technology, which is applied in harvesting platforms, digging harvesters, harvesters, etc., can solve the problems of root cutting and transportation of green cabbage heads, can not achieve cutting height, and is difficult to ensure the quality of root cutting And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

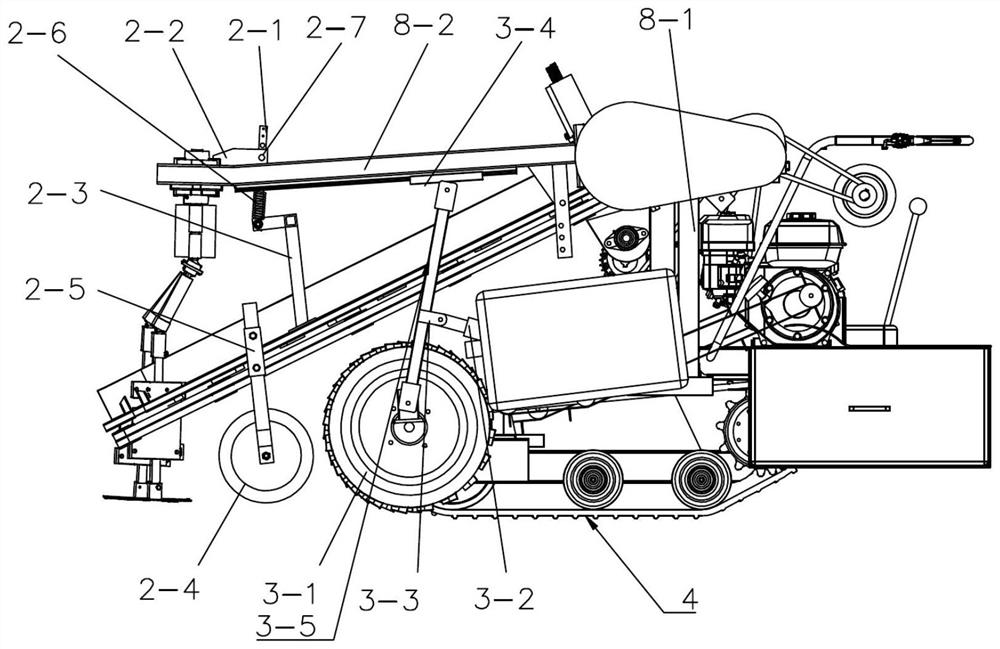

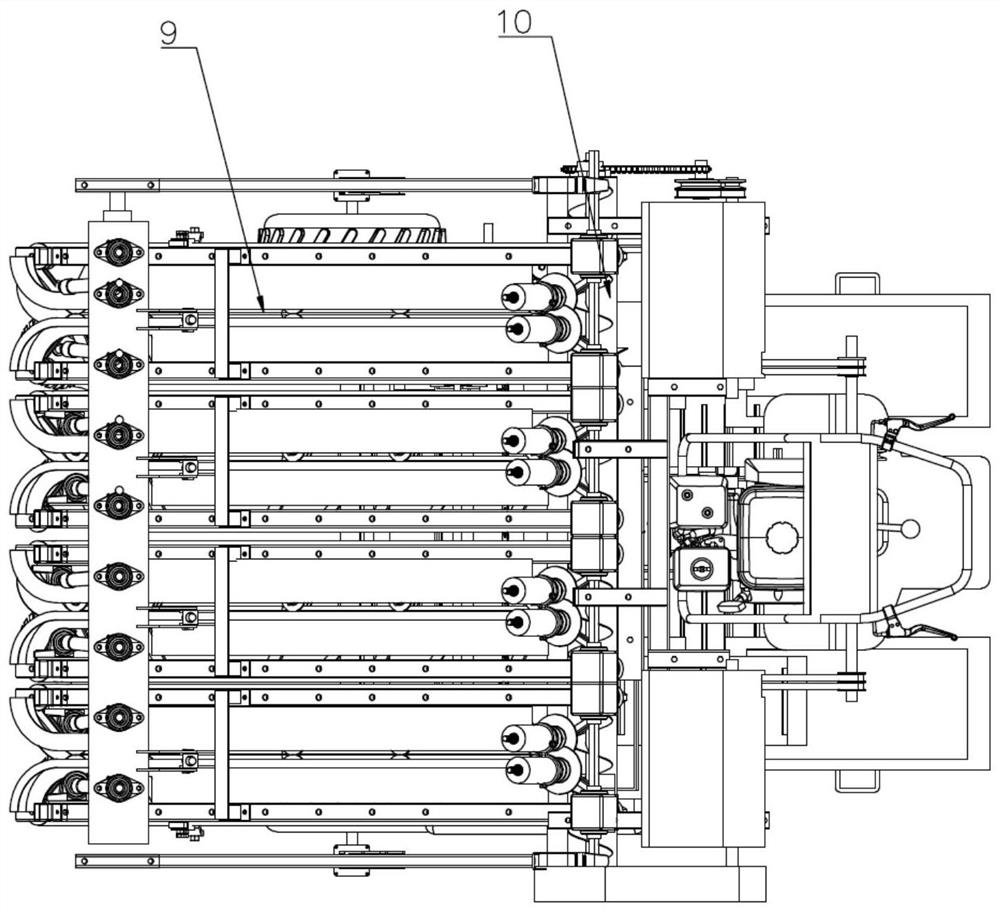

[0028] This embodiment is a four-row cabbage head multi-row combine harvester self-adaptive cutting platform, the specific structure can be found in Figure 1 to Figure 3 , the frame 8 on the crawler chassis 4 has a column 8-1 and a forward arm 8-2, the upper part of the column 8-1 is hinged to support the rear end of the clip blade lifting conveying mechanism 9, and the front end of the forward arm 8-2 is passed through the profiling The adjustment mechanism 2 is connected to the middle part of the clip blade lifting and conveying mechanism 9, the middle part of the front outrigger 8-2 and the upper end of the rubber wheel 3-1 strut form a horizontal movement pair through the slide rail 3-4, and the middle part of the strut is installed through a hinge The seat 3-3 is hinged with the extended end of the electric push rod 3-2 installed on the frame, thus forming a height adjustment mechanism 3, which can easily make the front outrigger 8-2 of the frame relative to the rubber wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com