Heating regenerative type deodorization method and device for air cleaner

An air purifier, heating and regeneration technology, applied in separation methods, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve the problems of reducing the effect of catalyst regeneration, difficult catalyst temperature, weak regeneration ability, etc., and achieve structural operation Simple, efficiency-enhancing, and convenient disassembly later

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

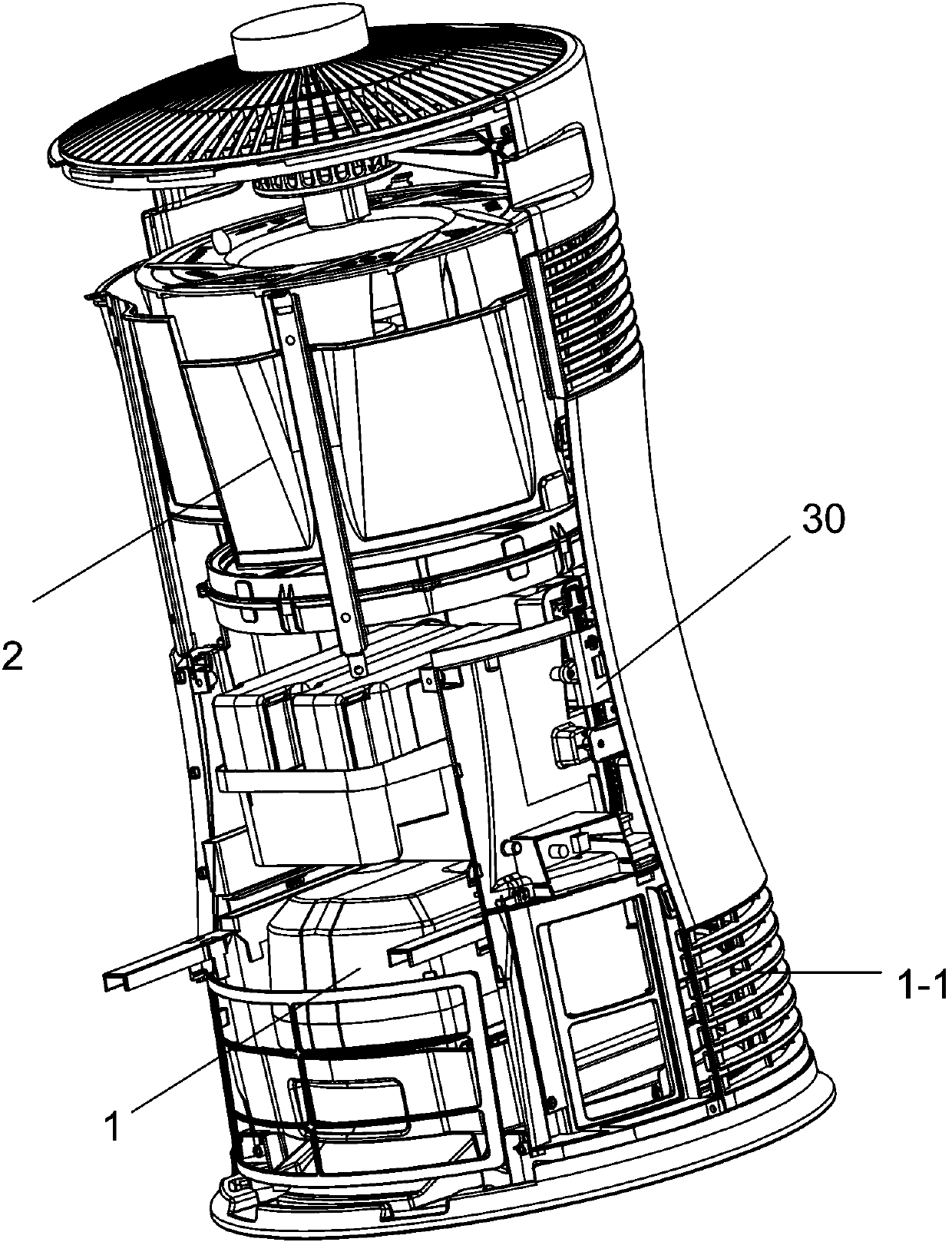

[0035] This embodiment discloses a heating regeneration deodorization method for an air purifier. When it is necessary to regenerate the catalyst to restore the deodorization performance of the catalyst, the catalyst is moved and the heat source is in direct contact with the catalyst to transfer heat. When the catalyst does not need to be regenerated and heated , the mobile catalyst is not in contact with the heat source.

[0036] Further, for the convenience of operation, the contact and non-contact states of the heat source and the catalyst are realized by using a motor to drive the catalyst to rotate and drive the heat source to move up and down.

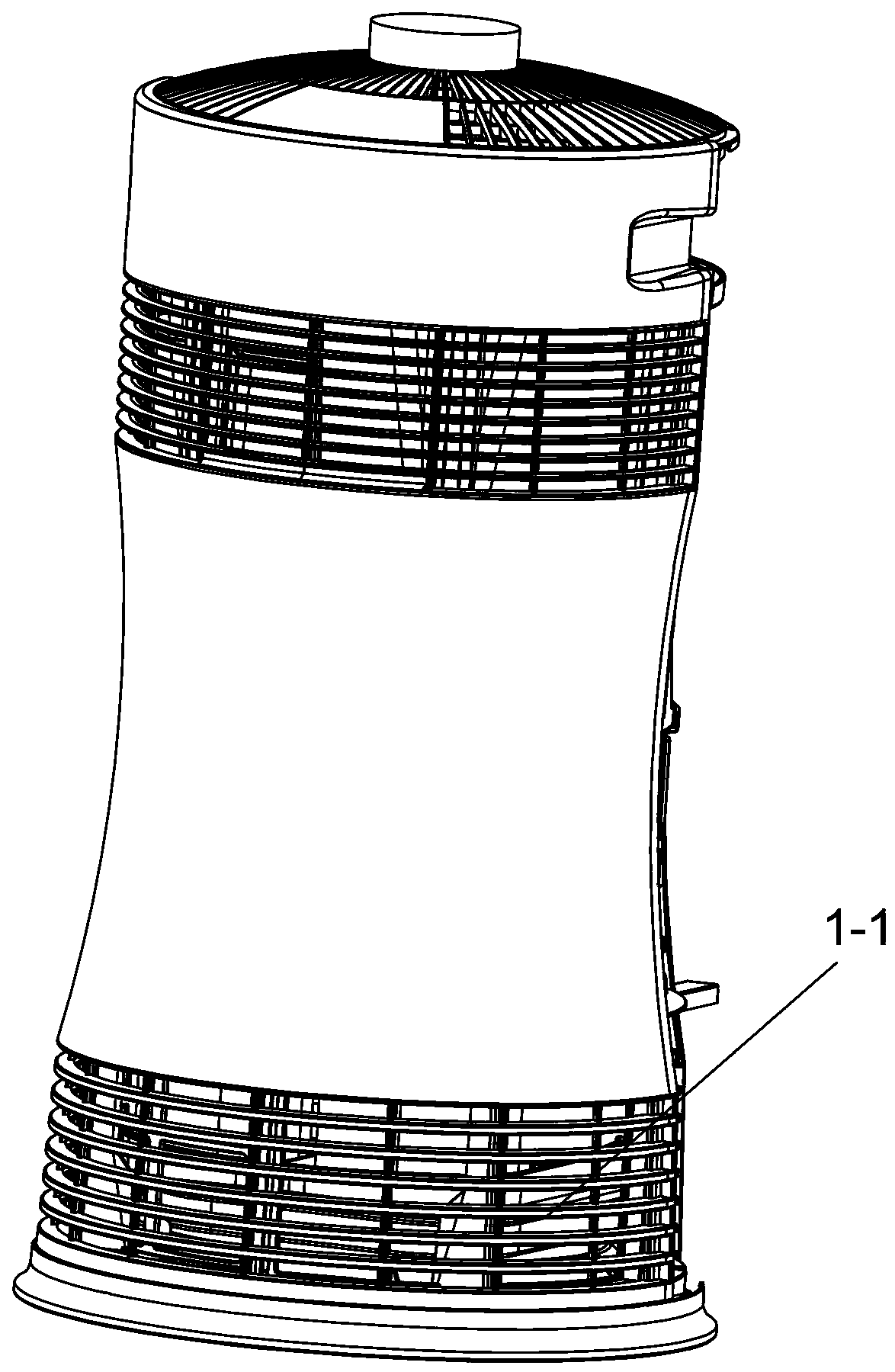

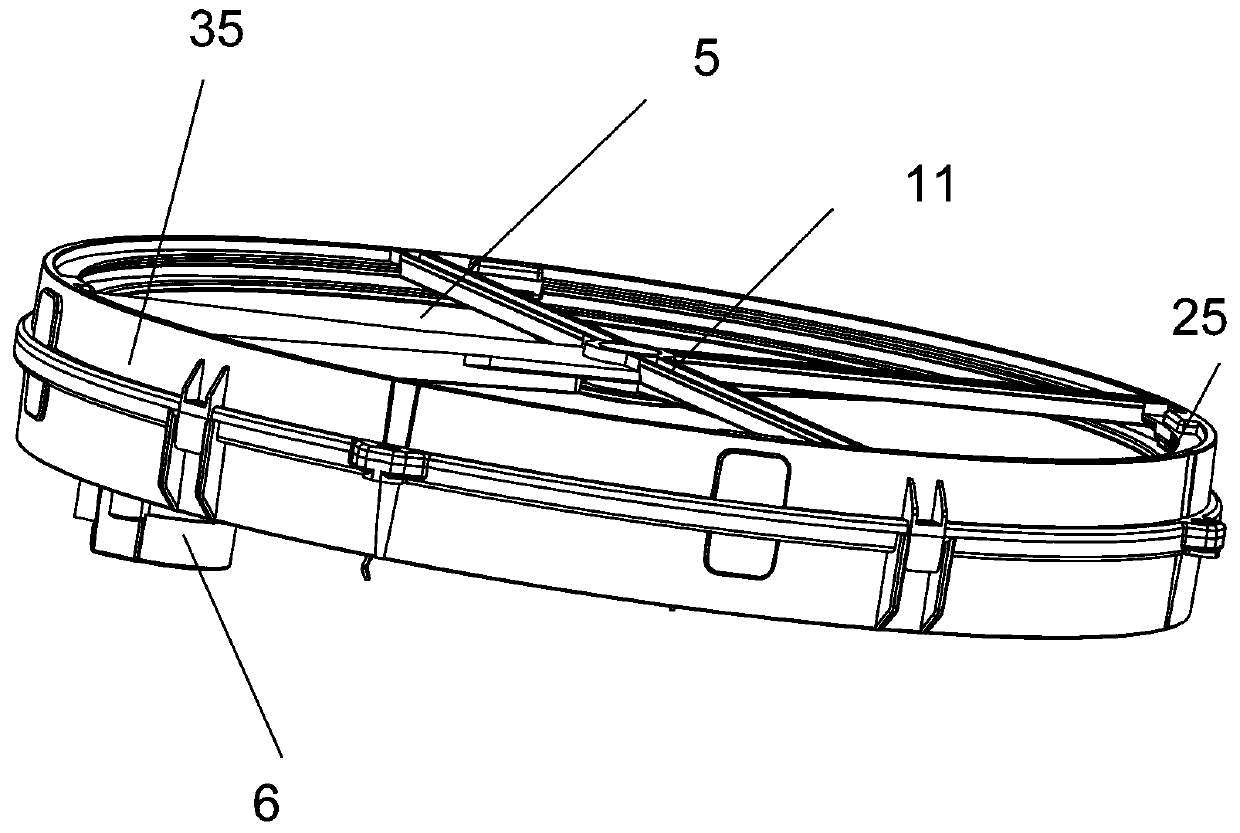

[0037] Such as Figure 1-12As shown, the present embodiment also provides a heating regeneration type deodorization device for an air purifier, which includes a ring fixing frame 35 with a through hole in the center, and a ring-shaped catalyst bracket 4 is sleeved in the ring fixing frame 35. Disc-shaped catalyst 5 is fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com