Power distribution overhead line grounding wire mounted robot and operating method thereof

An overhead line and robot technology, which is applied to overhead lines/cable equipment, circuits, conductive connections, etc., can solve problems such as inability to go online and offline easily, and achieve the effect of simple structural design principle, improved docking success rate, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

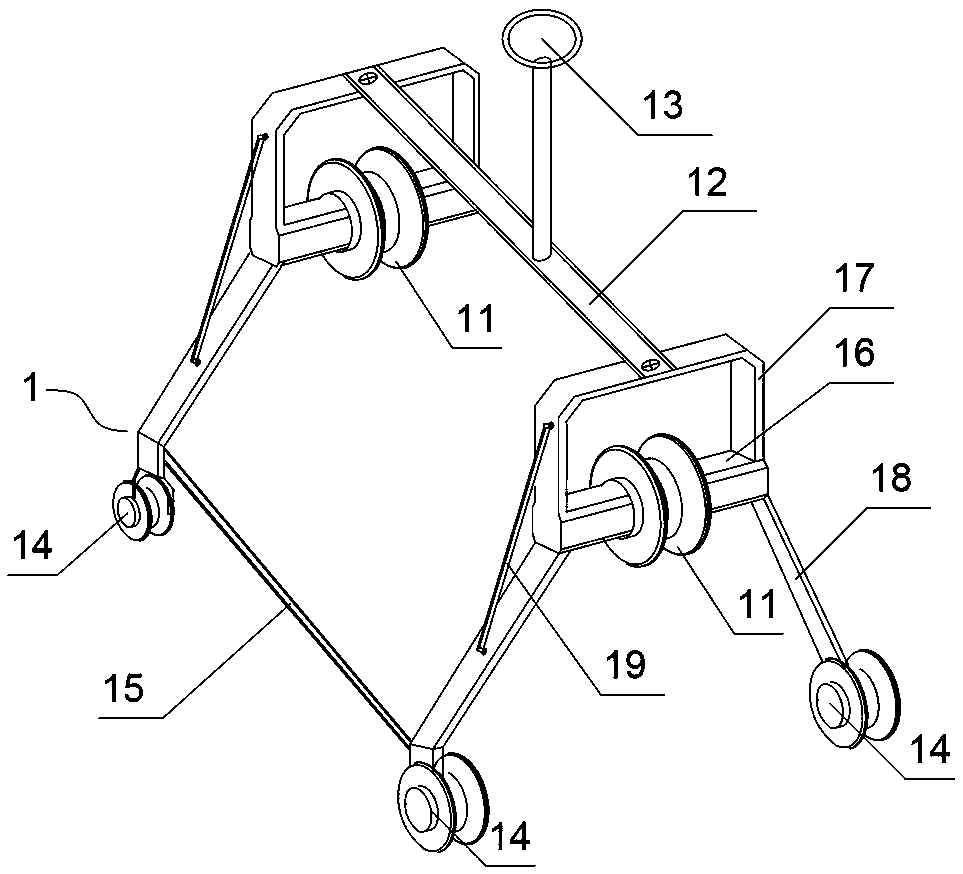

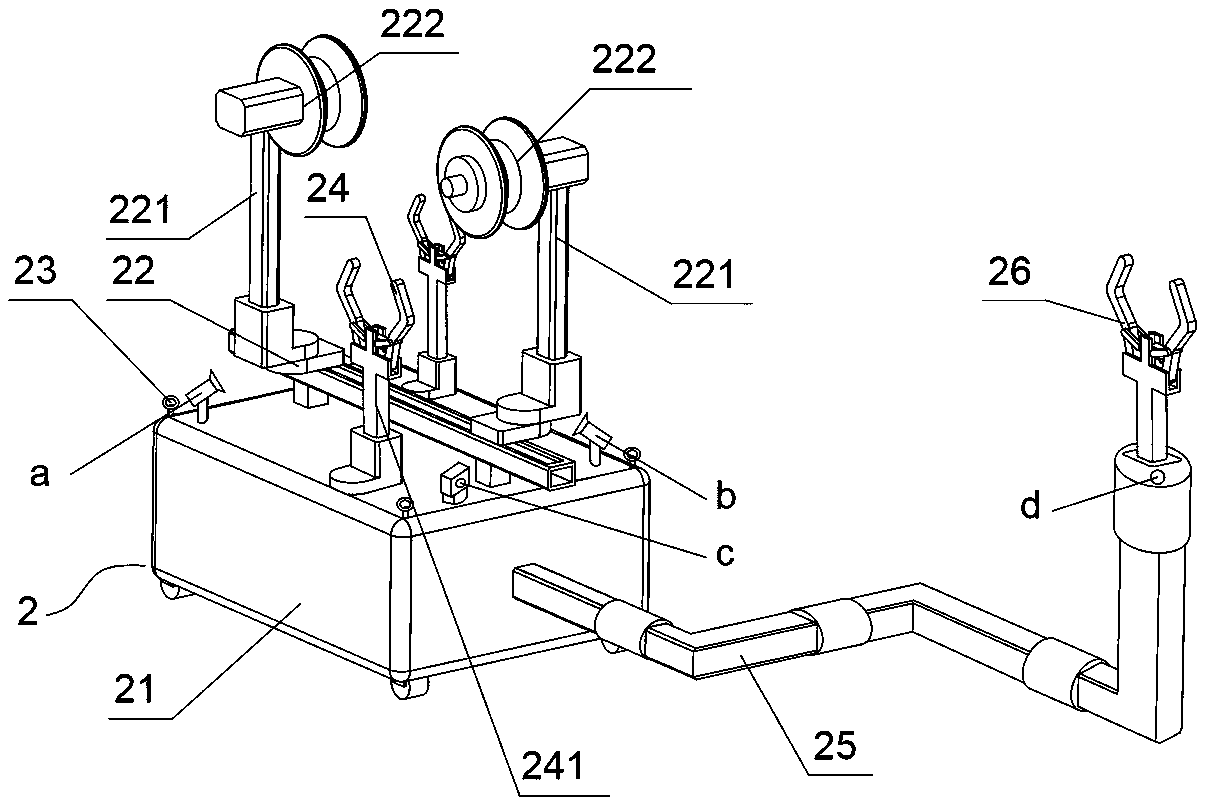

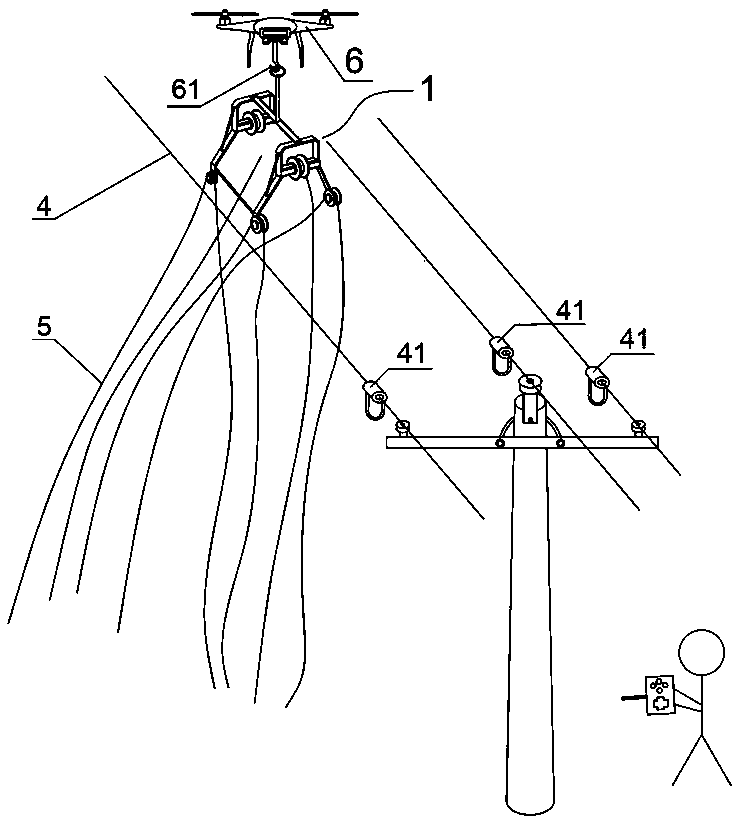

[0045] like figure 1 and figure 2 As shown, the robot for hanging the grounding wire of the power distribution overhead line in this embodiment includes an online traction robot 1 and a working robot 2 for performing the grounding wire hanging operation, and the online traction robot 1 includes a pair of first wires arranged at intervals along the walking direction Walking wheel 11, cross arm 12 is installed between the fixed support of the first lead wire walking wheel 11, and cross arm 12 is provided with unmanned aerial vehicle articulated ring 13, has a pair of traction pulley 14 that is arranged at intervals on the fixed support, and a The docking shaft 15 for docking with the work robot 2 is connected between the fixed brackets of the first wire walking wheel 11; The working mechanism 26 can conveniently use the insulating rope to hoist the working robot 2 through the traction pulley 14, so as to realize the detachable on-line and off-line operation mode. line puzzle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com