Building formwork connecting device and construction method thereof

A technology for connecting device and building formwork, which is applied in the connection parts of formwork/formwork/work frame, formwork/formwork/work frame, construction, etc. Realize problems such as quick installation, and achieve the effect of saving manpower, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

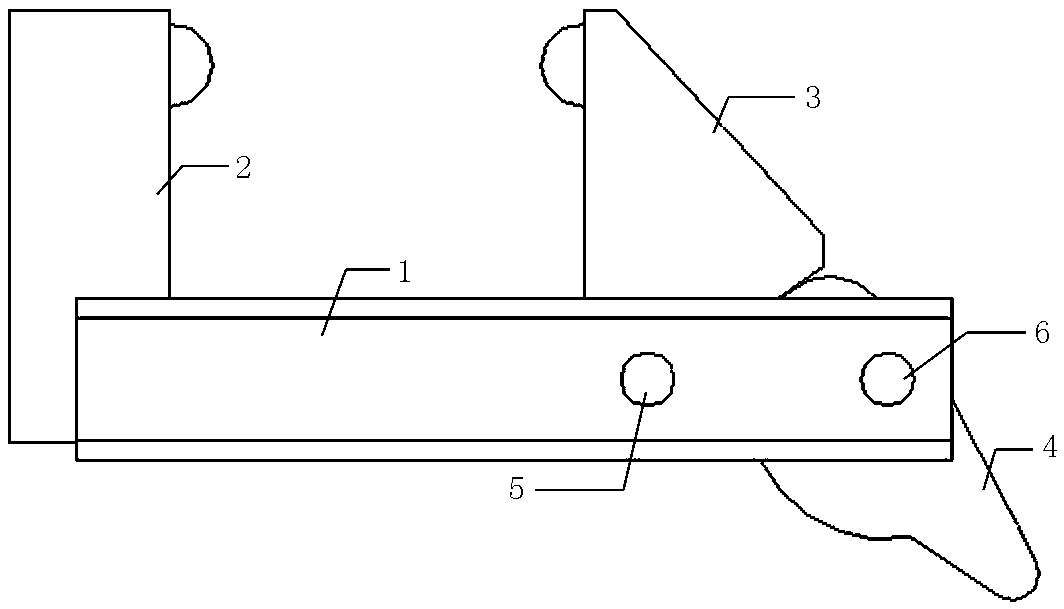

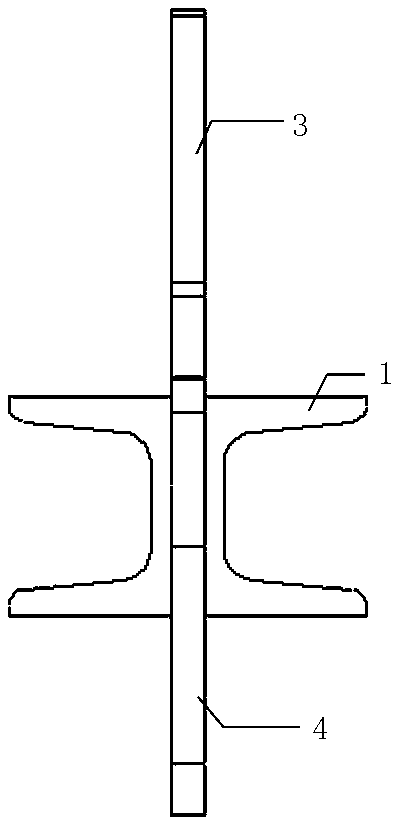

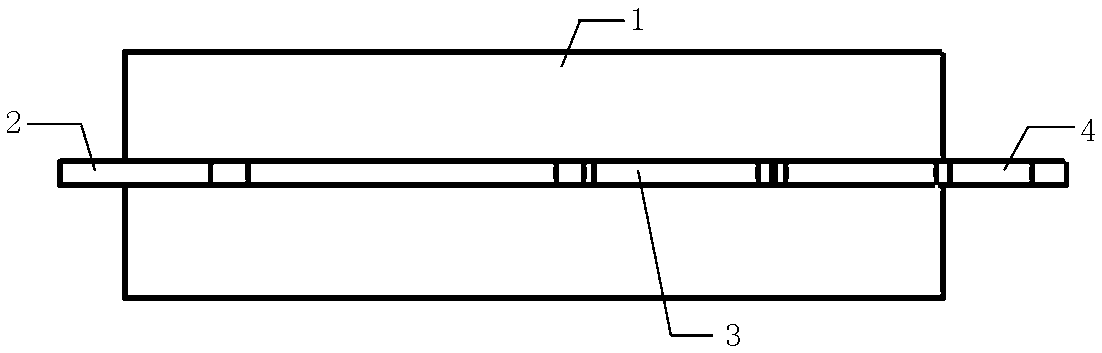

[0051] A building template connection device and its construction method, see Figure 1 ~ Figure 3 As shown, the building formwork connecting device includes a pair of U-shaped main beams 1 arranged in the back direction, a fixed tightening plate 2 fixedly connected between one end of the pair of U-shaped main beams 1, and a pair of U-shaped main beams 1 that are movably connected. The movable tightening plate 3 and the cam tightening piece 4 between the other ends of the shaped main beam 1, the cam tightening piece 4 is located outside the movable tightening plate 3, and the end faces of the two are connected.

[0052] see Figure 4 ~ Figure 6As shown, the fixed tightening plate 2 is a special-shaped plate structure, including a rectangular main board and a semicircular first protrusion protruding outward along the right side of the main board, and the first protrusion is located on the upper part of the main board The height of the main board is 135mm, the width is 50mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com