A kind of steel keel support system of building wooden formwork beam plate and its reinforcement method

A support system and construction technology, which is applied in construction, building structure, formwork/formwork/work frame, etc., can solve the problems of low beam formwork support work efficiency, consumption of wood construction waste, easy occurrence of exploding formwork, etc., to avoid The effect of producing a large amount of construction waste, improving the reinforcement efficiency, and preventing the expansion of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

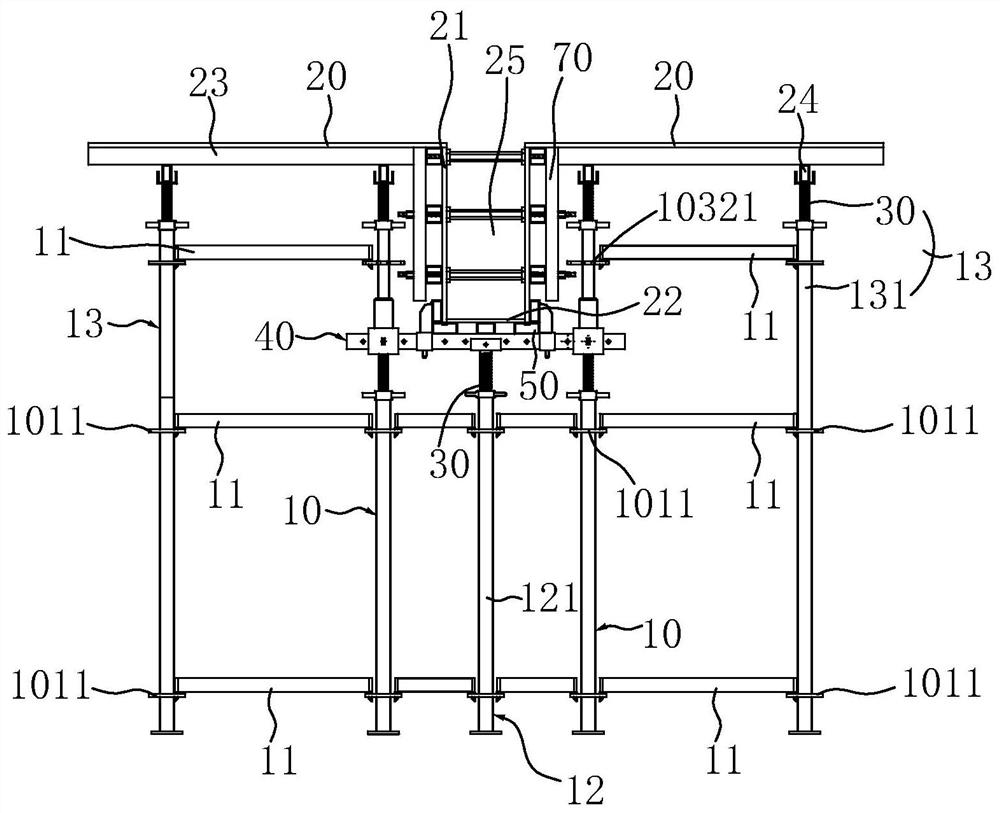

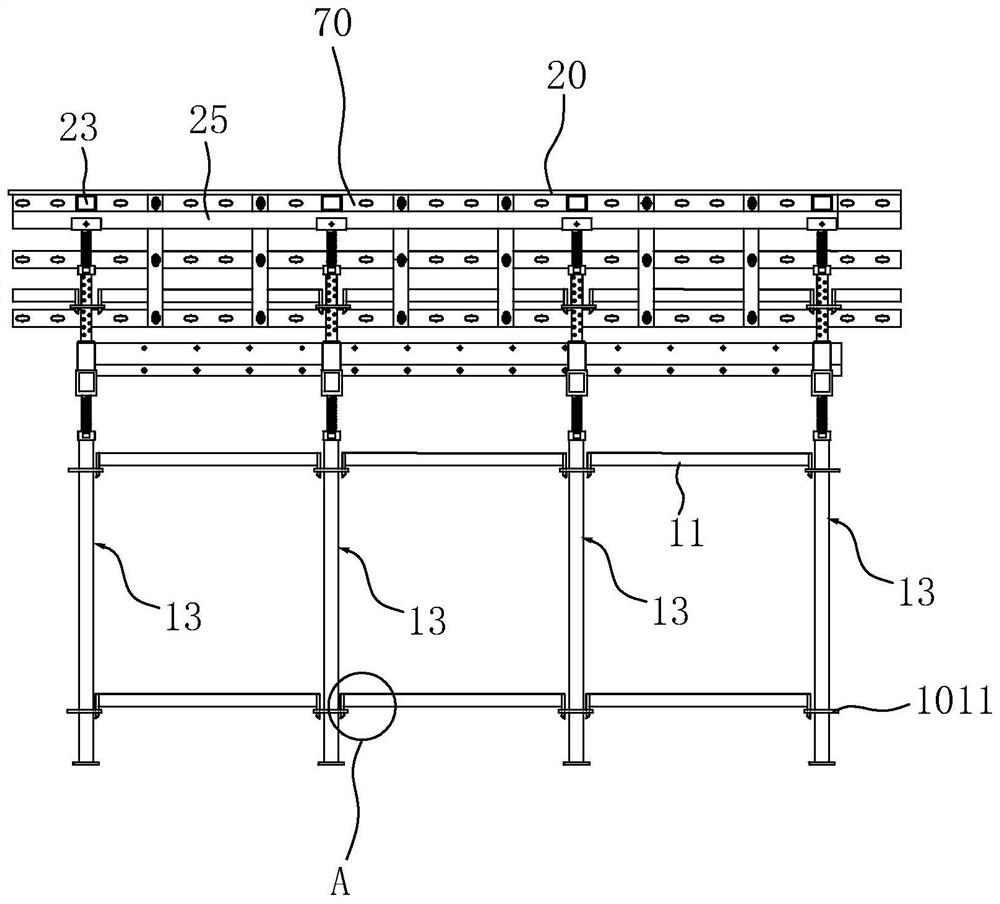

[0040] refer to figure 1 and figure 2, the present invention provides a steel keel support system for building wood formwork beam slabs, including multiple sets of support rod assemblies, the top of which is provided with a formwork; the formwork includes a horizontally arranged top plate 20, and two beam side plates 21 and a beam bottom plate 22 is a beam formwork groove-shaped structure 25, where the roof 20 is assembled on the top of the support rod assembly by keels, and the keels include roof sub-keels 24 and roof main keels 23 arranged in a matrix, and the roof main keels 23 are arranged on the roof sub-keels. Keel 24 top.

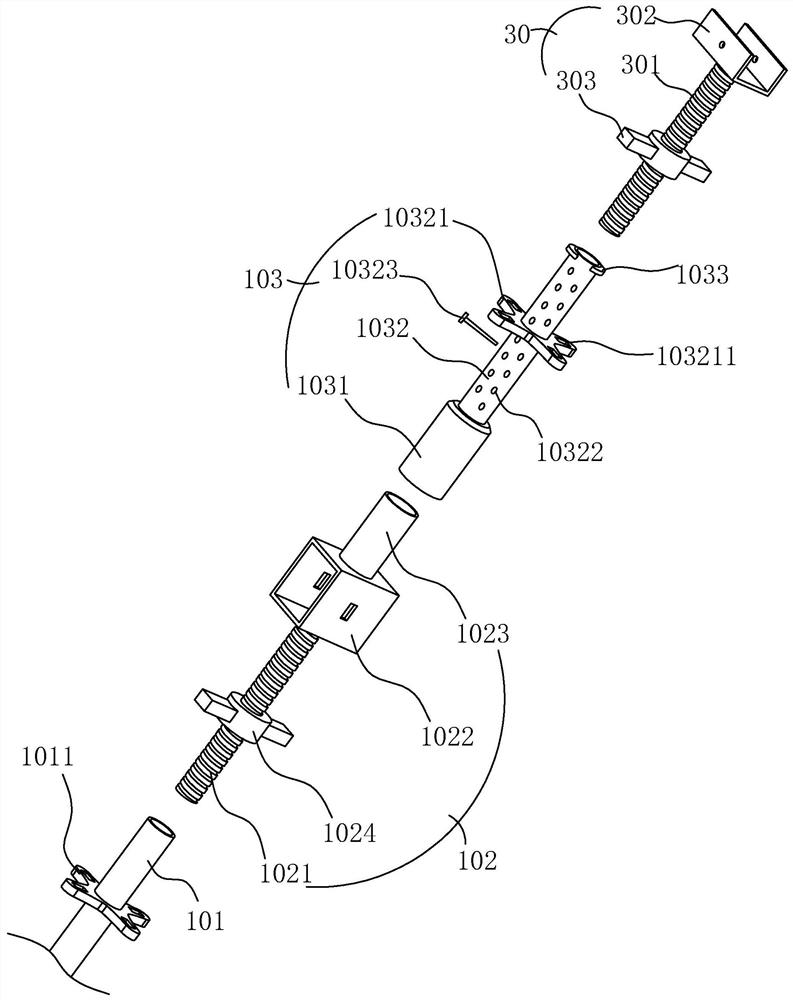

[0041] The support rod assembly includes a plurality of vertical rod support assemblies 10 on both sides of the main girder; the vertical rod support assemblies 10 on both sides of the main girder are used to support the sub-keel 24 of the roof, and are arranged on both sides of the groove-shaped structure 25 of the beam template; image 3 , the v...

Embodiment 2

[0057] For the present invention to provide a method for strengthening the steel keel of the wooden formwork beam slab, based on the steel keel support system of the wooden formwork beam slab in Embodiment 1, the specific steps for strengthening the main girder are:

[0058] S10: Arranging the vertical rod support assemblies 10 on both sides of the main girder and the adjacent top plate vertical rod increase assemblies 13 in a matrix at equal intervals, and installing the additional vertical rods 12 at the bottom of the beam in the middle of the vertical rod support assemblies 10 on both sides of the main girder;

[0059] S11: Adjust the movable buckle plate 10321 to the hole position corresponding to the cross row of holes on the same horizontal plane as the fixed buckle plate 1011 of the adjacent vertical pole, on the extended vertical pole piece 1032, the movable buckle plate 10321 Insert the buckle at the bottom to fix it on the designated hole, and then weld the bump 1033 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com