Inner supporting device of pipeline buckling joint and full-bore buckling connection method

A connection method and a technology of pipe joints, which are applied in the field of pipe joints, can solve problems such as affecting the safety performance of pipelines, difficulty in accurately controlling mechanical strength, and complex structure levels, so as to improve service life and work quality, and are not easy to fall off or break , The effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure and working principle of the inner supporting device of a pipe crimping joint provided by the present invention will be further described in detail below with reference to the accompanying drawings.

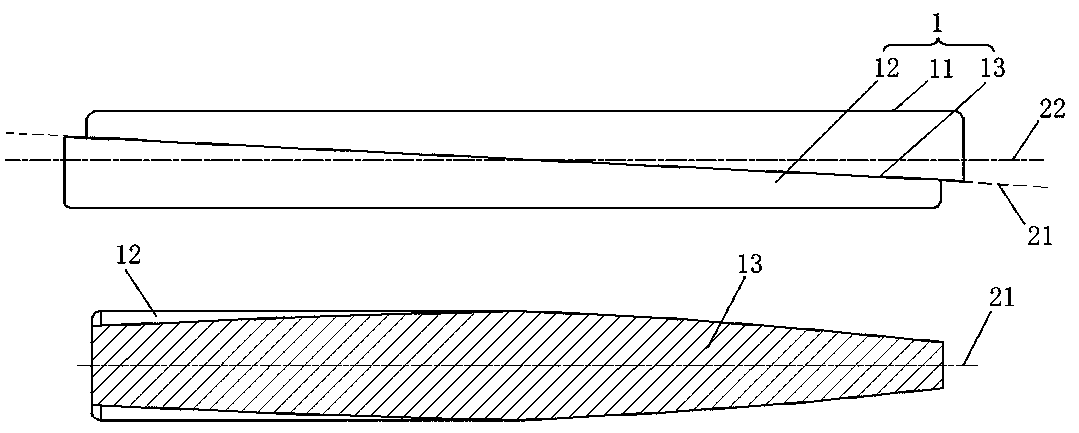

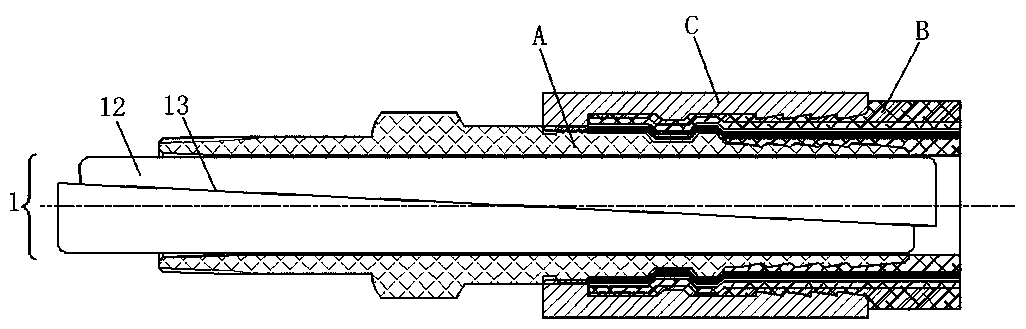

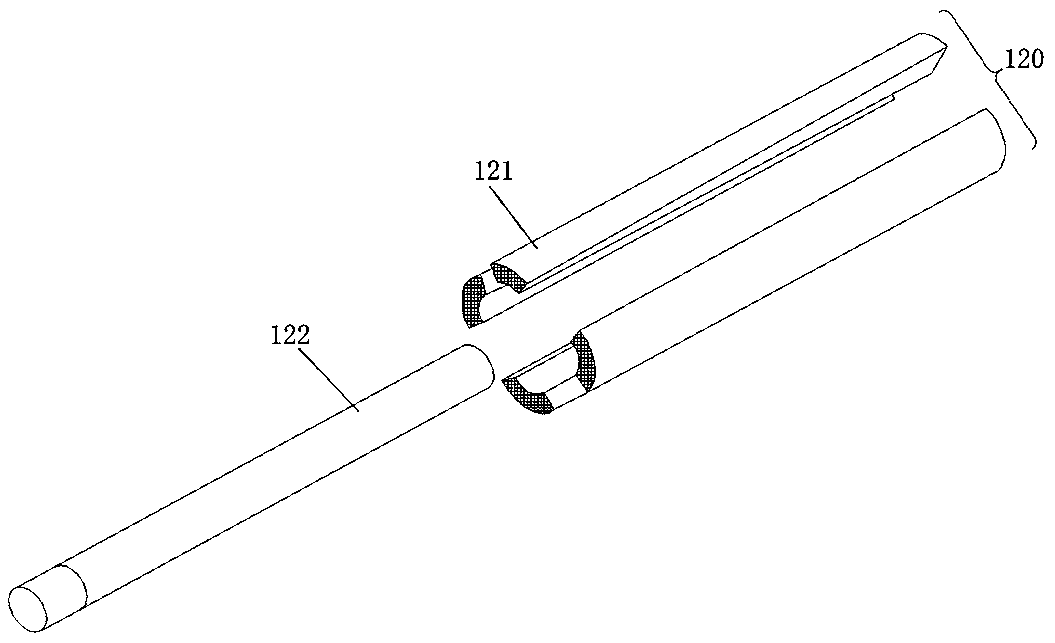

[0026] see figure 1 , is a schematic diagram of an internal support device for a pipe crimp joint provided by the invention. The structure constituting the inner support device mainly includes a support body 1 arranged in the joint core tube A, the surface 11 of the support body 1 is attached to the inner wall of the joint core tube A, wherein the support body 1 is composed of two or more support bars 12 Assembled, the support bar 12 has a wedge-shaped splicing surface 13 .

[0027] Its working principle is: insert the support strips 12 of the internal support device into the joint core tube A in sequence to form a support body 1. Since the support strips 12 have a wedge-shaped splicing surface 13, for the convenience of operation, firstly insert one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com