Double-channel heating device

A heating device, dual-channel technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of lack of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

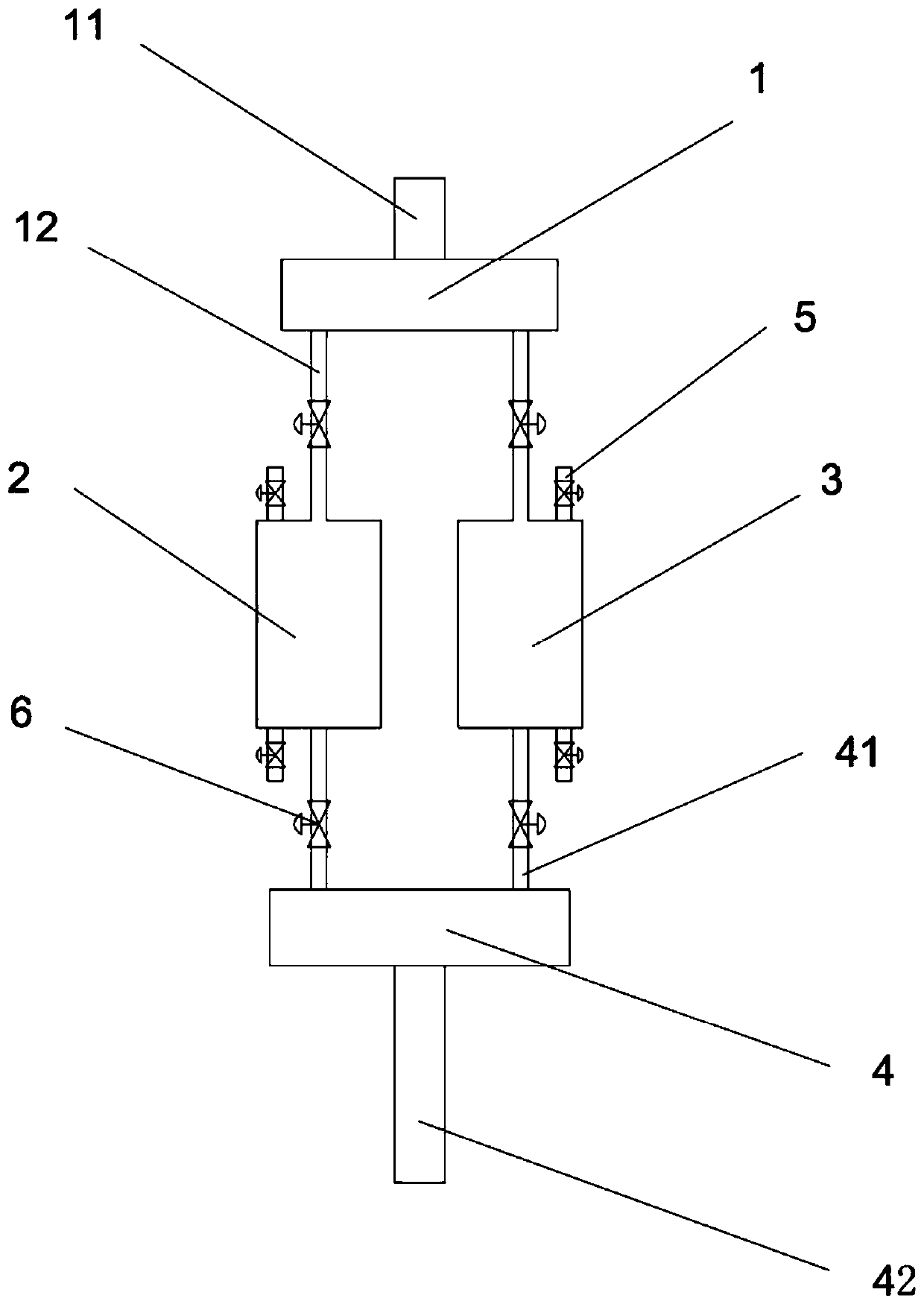

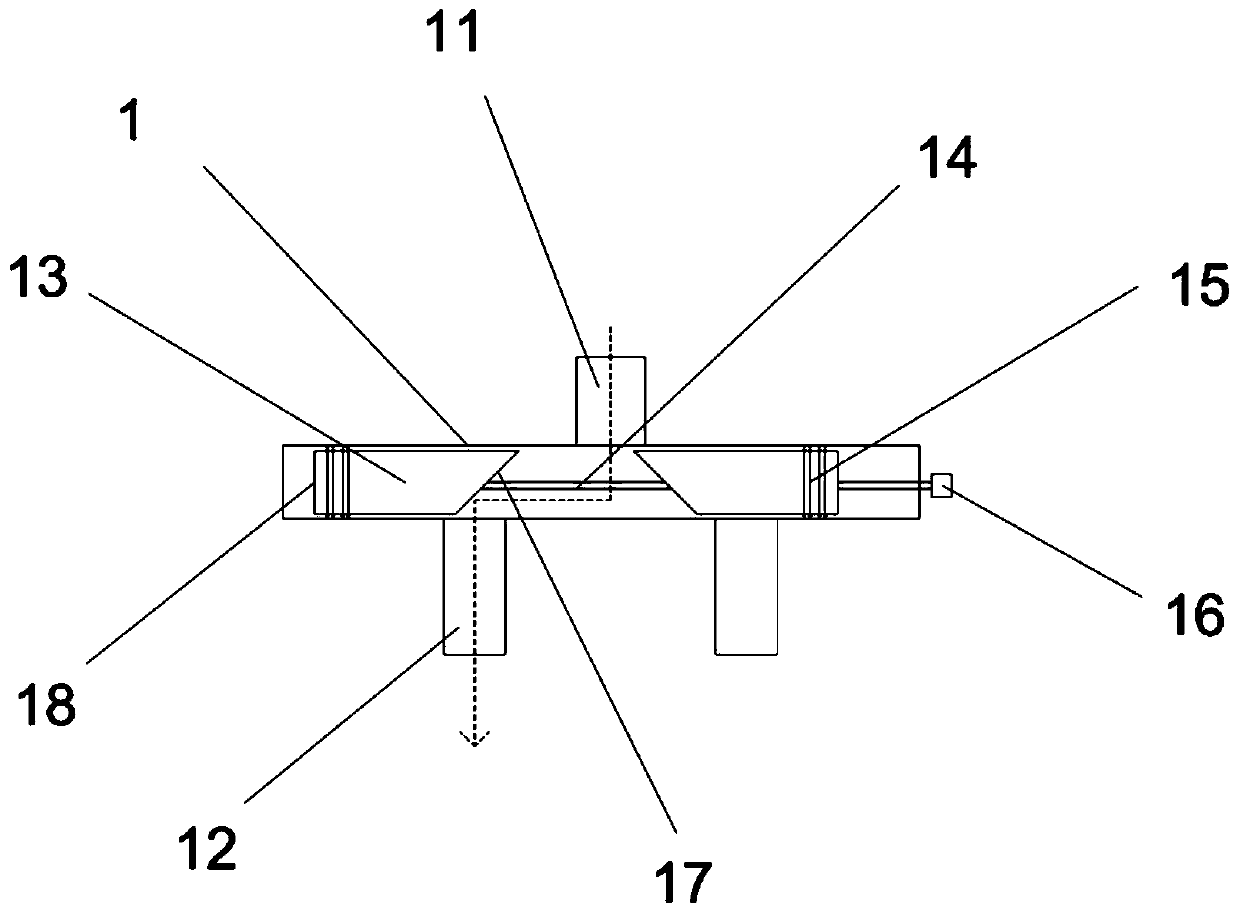

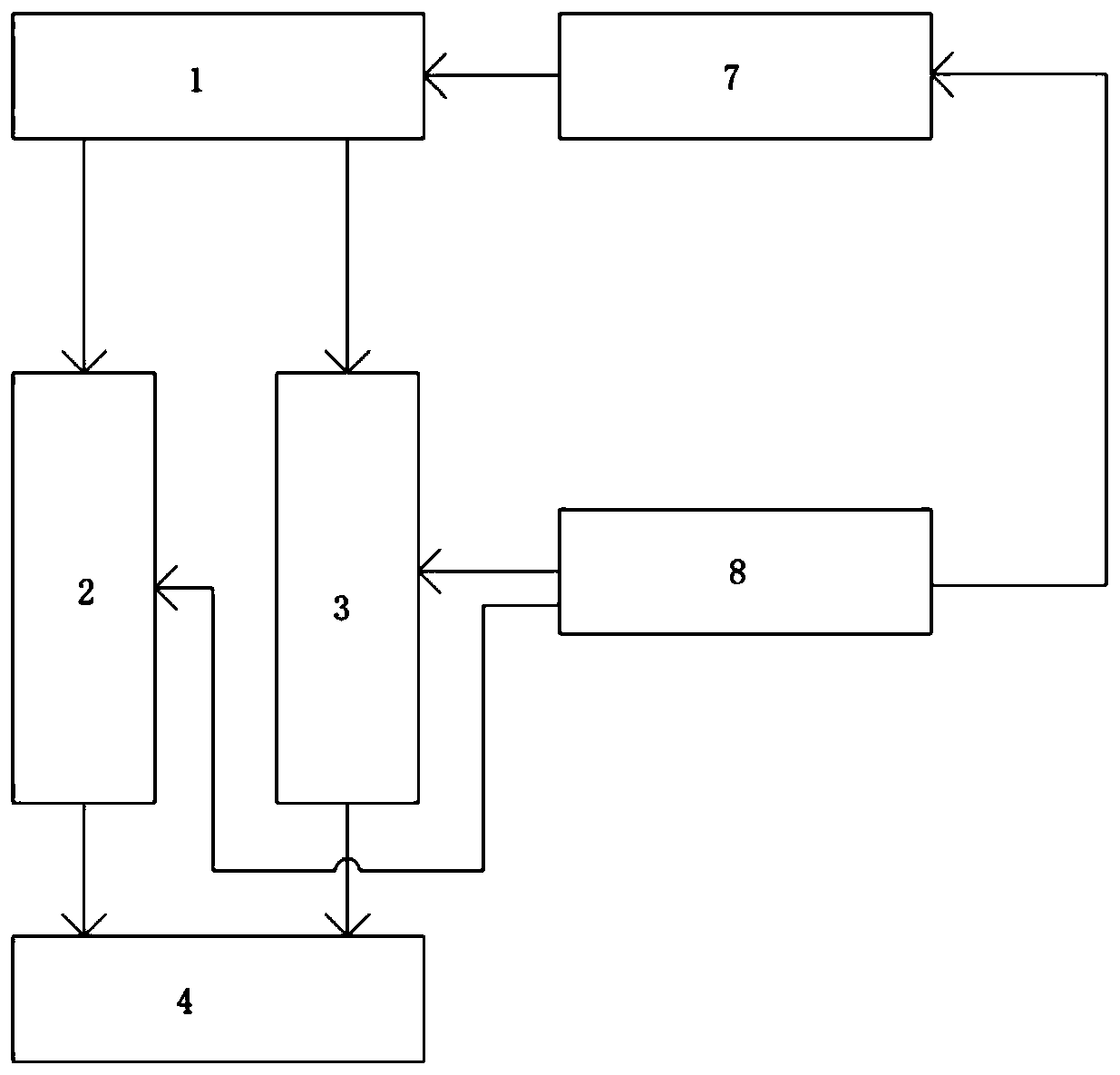

[0022] Such as Figure 1-2 As shown, a dual-channel heating device includes a body and a three-way valve 1, a heating furnace, and a three-way mixer 4 arranged on the body. It is characterized in that: the heating furnace includes a first heating furnace 2 and a second heating furnace. Furnace 3; The body is provided with an airflow controller 7 and a temperature controller 8 connected; the airflow controller 7 is connected to the three-way valve 1; the temperature controller 8 is connected to the first heating furnace 2, the second The heating furnace 3 is connected; the three-way valve 1 includes an inlet flange 11 and two outlet flanges 12, and the two outlet flanges 12 are respectively connected to the air inlets of the first heating furnace 2 and the second heating furnace 3; The gas outlets of the first heating furnace 2 and the second heating furnace 3 are respectively connected to the two mixing inlet pipes 41 of the three-way mixer 4; the first heating furnace 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com