A bulge design method for suppressing high-speed impulse noise of helicopter rotor

A helicopter rotor and high-speed pulse technology, which is applied in design optimization/simulation, sustainable transportation, geometric CAD, etc., can solve problems such as bulging design methods that have not been studied by anyone, and achieve simple structure, shock wave weakening, and convenient technical implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

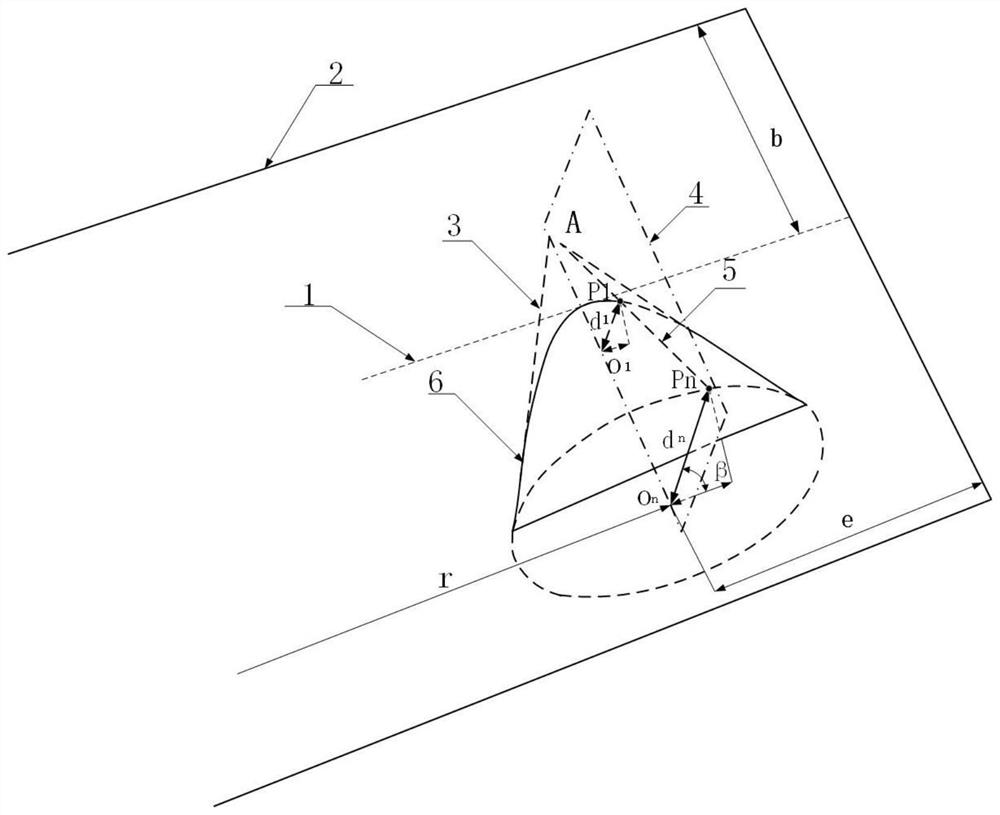

[0029] The following examples will be further described with reference to the accompanying drawings.

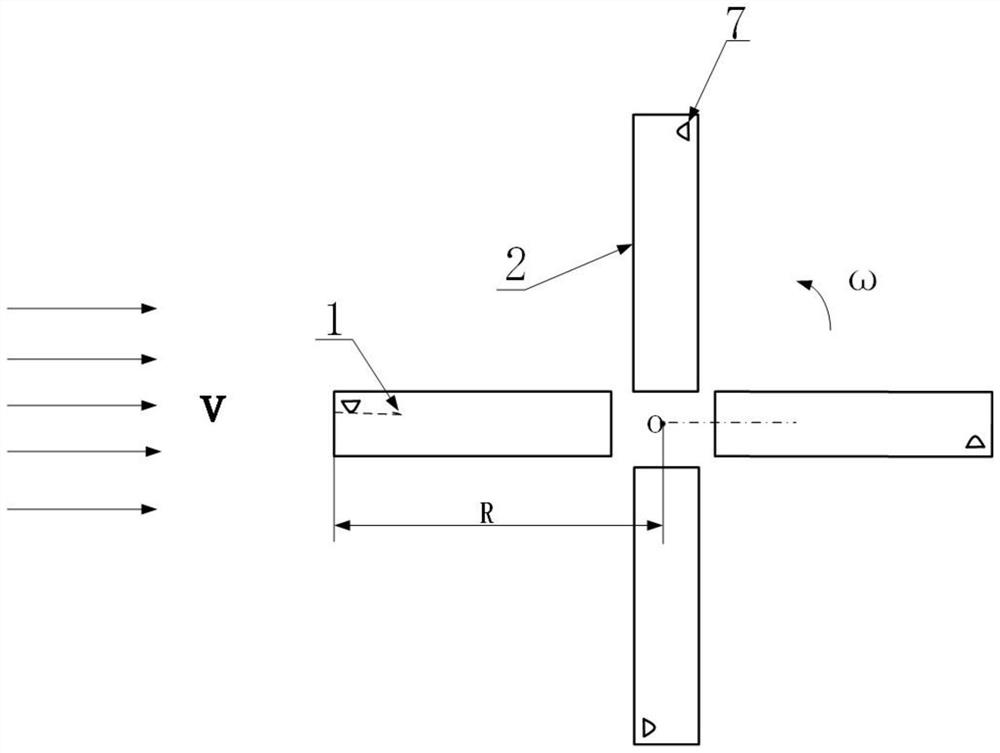

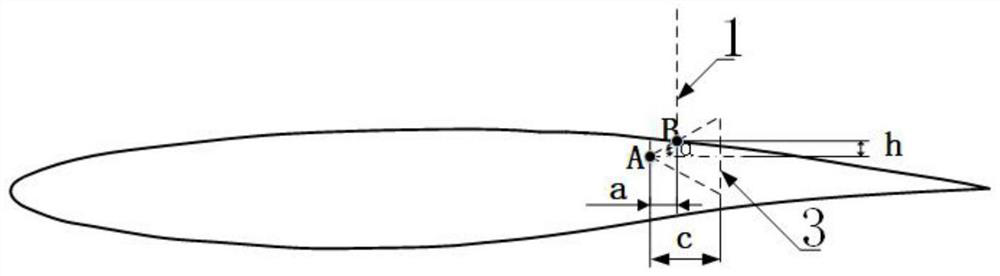

[0030] The rotor model of the embodiment of the present invention is as figure 1 As shown, the embodiment of the present invention proposes a method of suppressing a rotor high-speed pulse noise in a rotor bladed pin design drum bag, and the specific embodiment includes the following steps:

[0031] 1) Determine the design point status of the rotor blade drum bag

[0032] The rotor high-speed pulse noise occurs on the hippower of the rotor, the forward paddle tip speed is a superposition of the rotor itself rotational speed and the helicopter front speed. The design point state of the rotor pip drum bag of the present invention is a reference, m = (v + ωr) / A0, where V is a helicopter speed, ω is a rotor rotation angle velocity of the helicopter. , R is the radius of rotor blades 2, and A0 is a sound speed. The design point status of the rotor blade drum bag is m = 0.9-1.05.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com