A multi-strand cable laying spacer

A spacer and cable technology, applied in the direction of electrical components, etc., can solve the problems of maintenance and replacement, inability to tension cables, and high laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

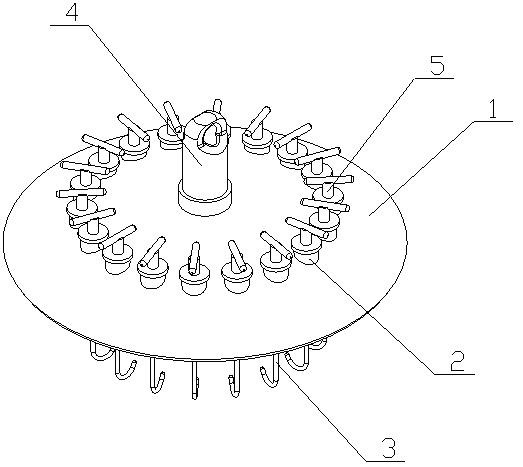

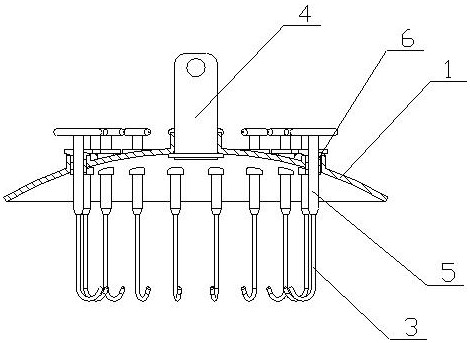

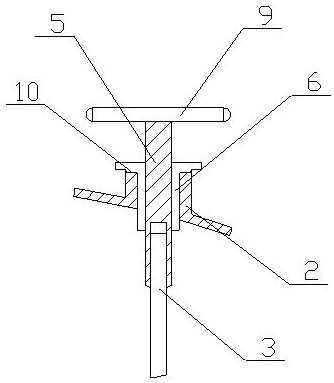

[0017] A multi-strand cable laying spacer of the present invention is realized in this way: a multi-strand cable laying spacer of the present invention consists of a main disc body 1, a fixing sleeve 2, a pulling rod 3, a main fixing column 4, and a main pulling rod 5 , screw sleeve 6, fixed ring 7, limit card slot 8, deflection rod 9 and limit boss 10, the fixed ring 7 is placed in the middle of the main disc body 1 and runs through the main disc body 1, the main fixed column 4 is placed In the fixing ring 7, one end is clamped on the main disk body 1 through the limit ring, and the other end protrudes from the main disk body 1. The other end of the main fixing column 4 has a fixed installation hole, and the main disk body 1 is Spherical crown structure, a plurality of fixed sleeves 2 are placed on the main disk body 1, the fixed sleeves 2 are distributed in a circle, the end surface of the fixed sleeve 2 is radially opened with a limit card slot 8, and a plurality of screw sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com