Charging control method and device

A charge control method and charge control technology, applied to circuit devices, battery circuit devices, secondary battery charging/discharging, etc., to achieve the effect of lowering temperature and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

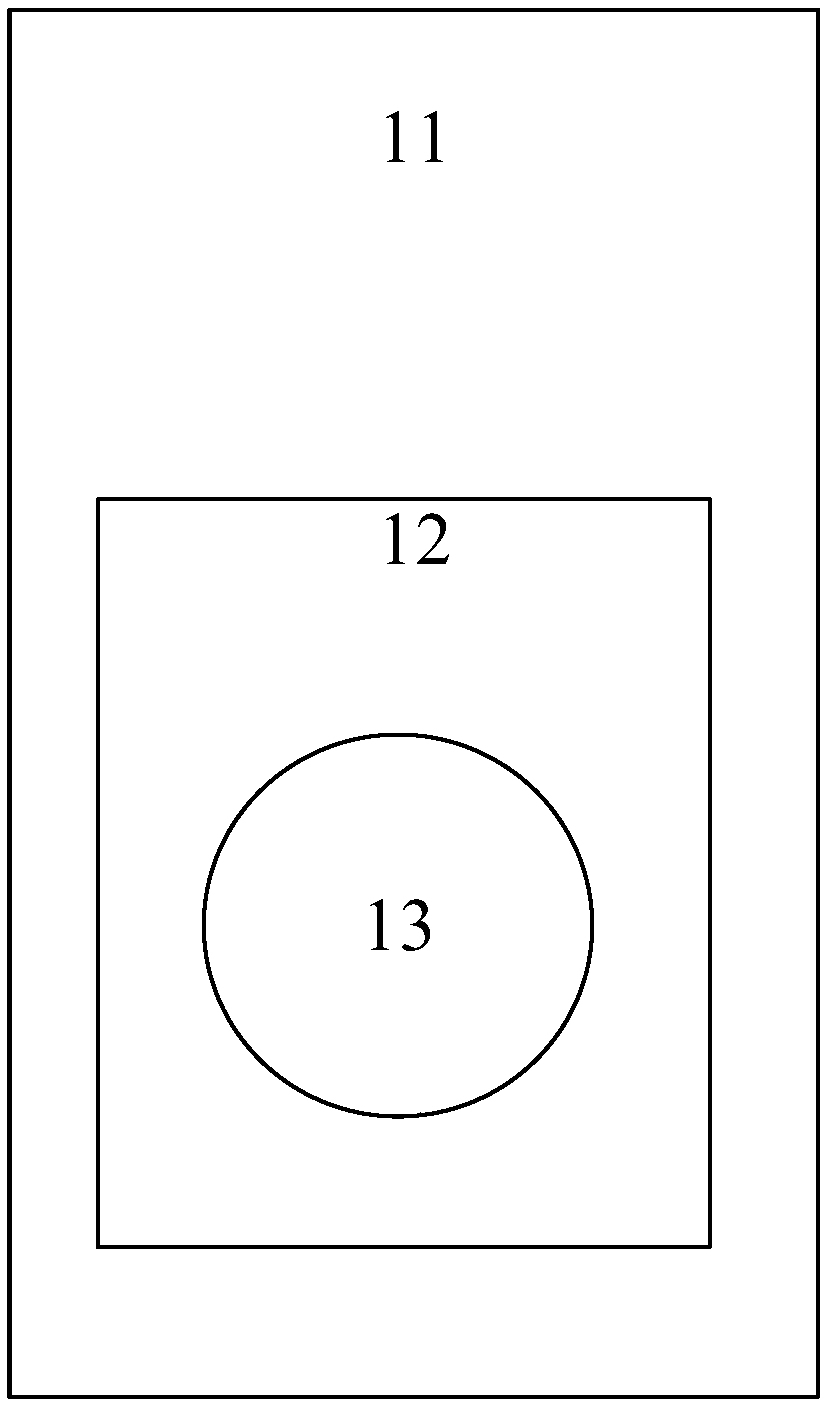

[0067] In order to better explain the present invention, the current charging technology is firstly introduced below.

[0068] Low-power wireless charging (receiving end power less than 5W) has gradually withdrawn from the market due to its slow charging rate and poor user experience. The latest standard of the wireless charging standard (QI) introduces medium-power wireless charging with the power of the receiving end greater than 5W and less than 15W, and this increase in power will be accompanied by serious heating problems in practical applications.

[0069] When researching 5 to 15W wireless charging products, it is found that because the wireless charging terminal only has a higher charging efficiency when it is at the center point of the wireless charging plate, the charging efficiency is about 70%, and the heat generation is relatively small. In order to ensure that the input power of the receiving end remains unchanged, the transmitting end often transmits at a higher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com