Fully automatic steamed stuffed bun machine

A steamed stuffed bun machine, fully automatic technology, applied in the field of fully automatic steamed stuffed bun machine, can solve the problems of instability, easy to break the chain, high friction of upgrading, etc., to save production costs, realize fully automatic processing, and eliminate the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following describes the implementation of the present invention with reference to the drawings and preferred embodiments.

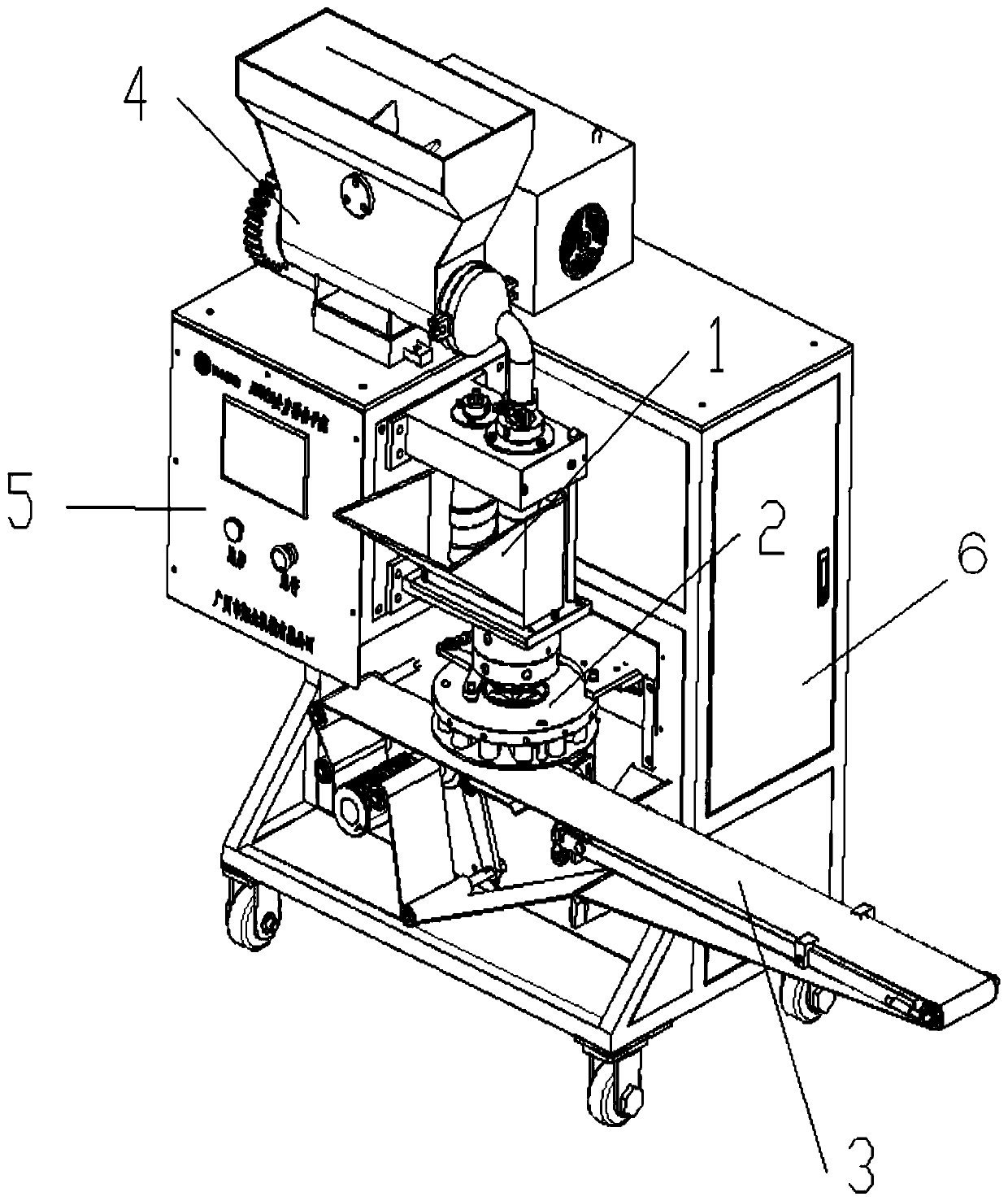

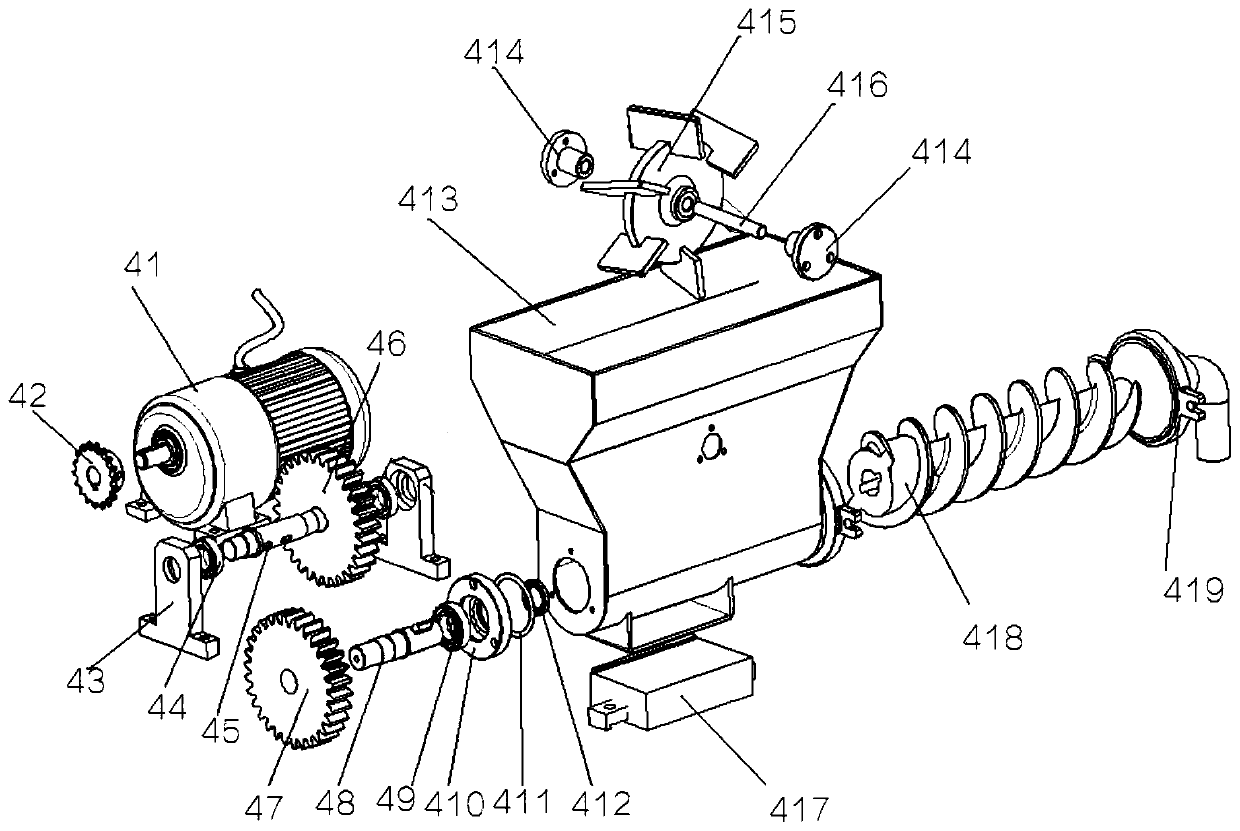

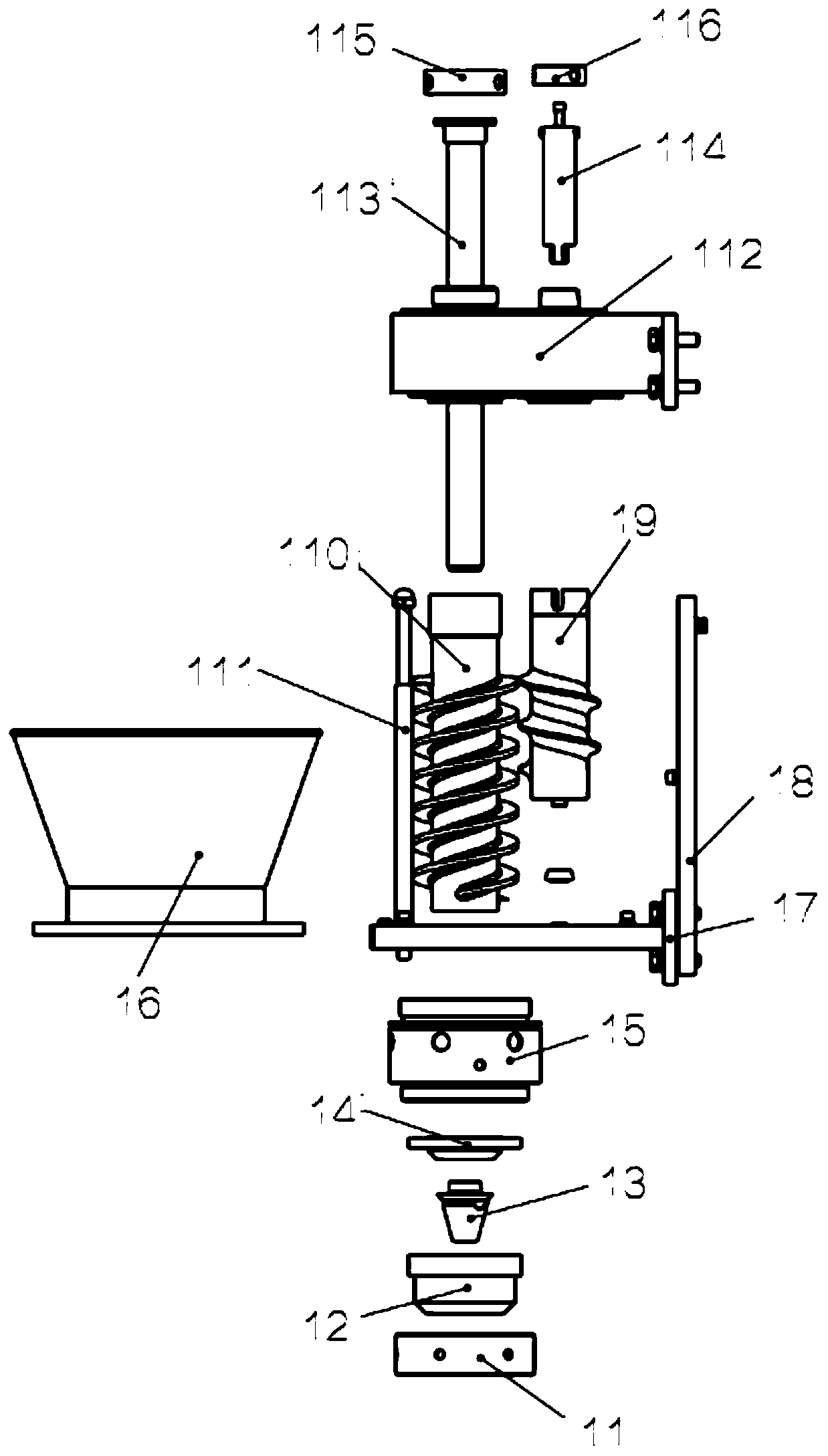

[0018] See Figure 1-Figure 5 As shown in combination, a fully automatic steamed bun machine includes a rack 6, an electric control box 5 is installed on the front side of the rack 6, and a stuffing ejection mechanism 4 is installed above the electric control box 5. A conveying mechanism 3 is installed on the front side of the frame 6, and a forming mechanism 2 is arranged above the output mechanism 3. The filling mechanism 4 and the forming mechanism 2 are connected by the surface mechanism 1. The stuffing mechanism 4 includes a stuffing drive motor 41 installed above the frame 6 and a stuffing hopper 413 installed on the electric control box 5. The power output end of the stuffing drive motor 41 is installed with The motor sprocket 42, the bottom of the filling hopper 413 is provided with a filling screw 418, and the head end of the filling scr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap