Belt conveyer weight box, weight system and belt correcting method

A belt conveyor and counterweight box technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of difficult to accurately control the counterweight of belt conveyors, avoid excessive loading, and ensure stable operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

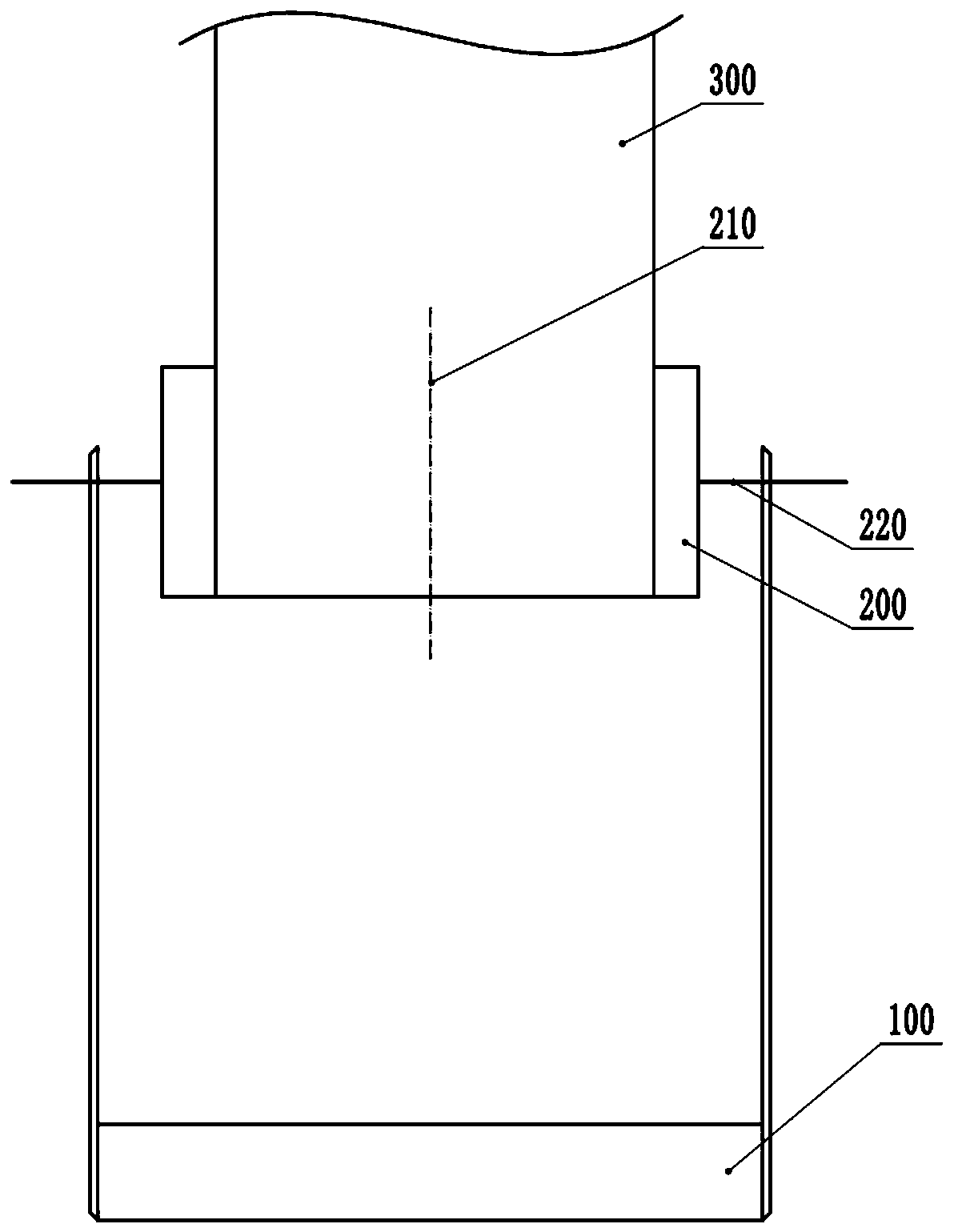

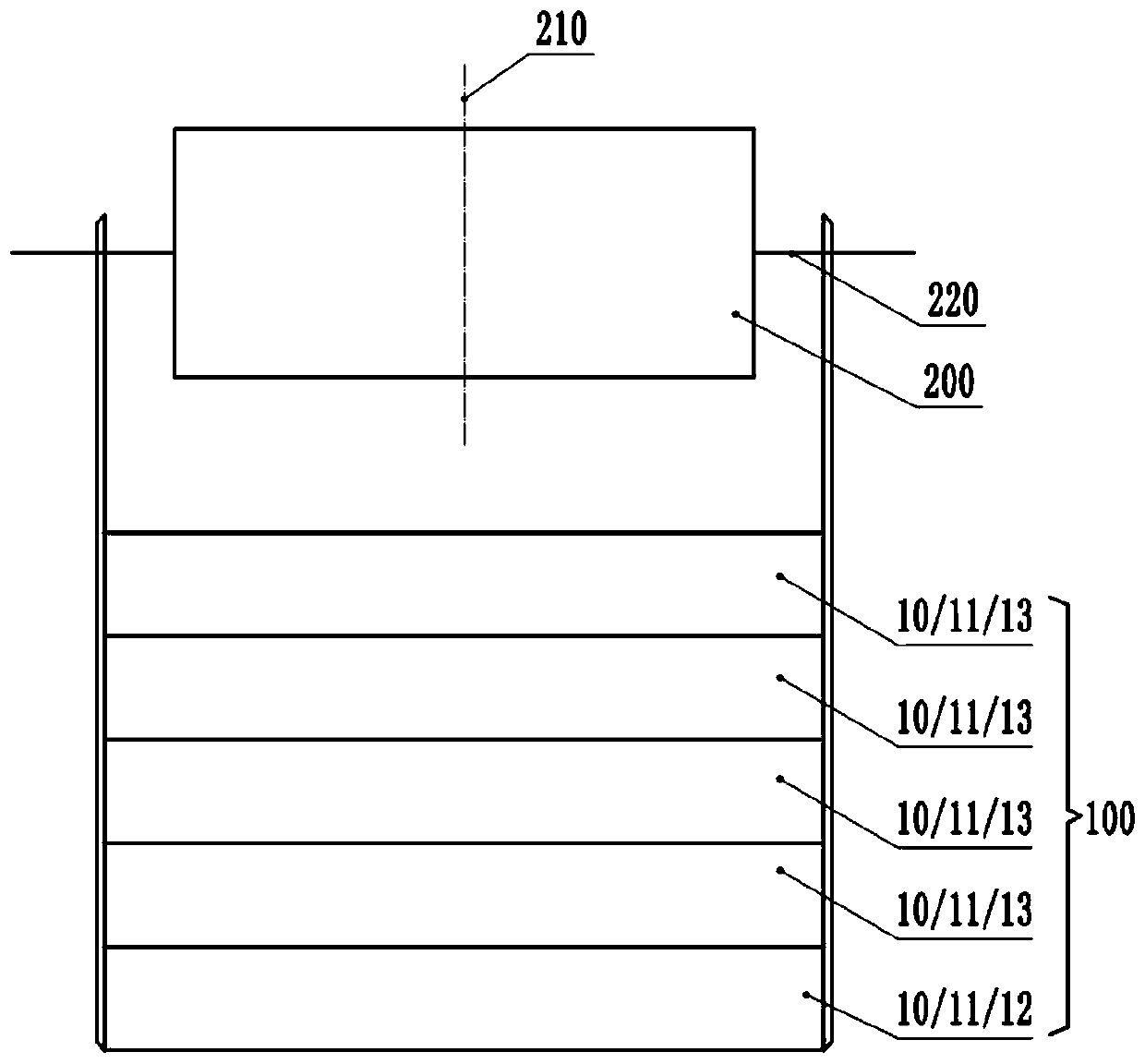

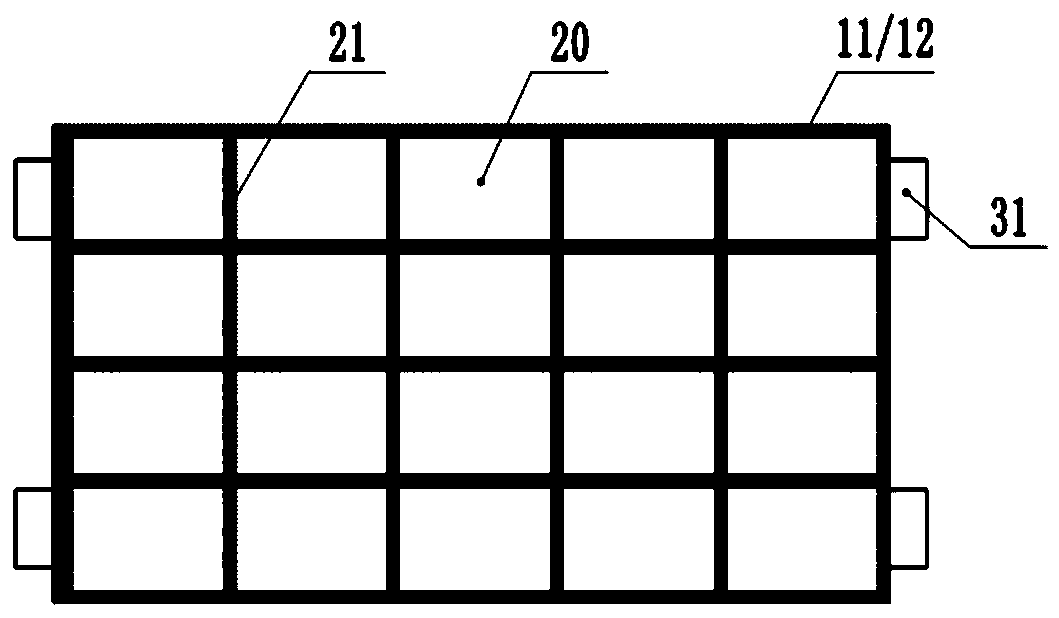

[0048] The invention provides a belt conveyor counterweight box, such as figure 1 and figure 2 As shown, the counterweight box includes: a box body 100, which can be suspended and connected to the roller 200 in the belt conveyor; at least two layers of counterweight layers 10 are arranged in the box body 100, and each counterweight layer 10 is provided with a plurality of The counterweight compartments 20 for accommodating the counterweights 40 are distributed in a matrix.

[0049] When the counterweight box is used, the counterweight 40 matching the counterweight compartment 20 is placed in the counterweight compartment 20 . On the one hand, it is convenient to control the number of counterweights 40 loaded, so as to control the weight of the counterweights more accurately; and, the counterweight box limits the maximum number of counterweights 40 that can be loaded, which can avoid loading In case of overdose.

[0050] On the other hand, the counterweight box is provided ...

Embodiment 2

[0059] The invention provides a belt conveyor counterweight system, such as Figure 6 As shown, the counterweight system includes: a counterweight 40 and the above-mentioned belt conveyor counterweight box, the counterweight 40 is arranged in the counterweight compartment 20 of the counterweight box, and the counterweight box and the roller 200 in the belt conveyor The connection can pull the drum 200 to move in translation; along the axial direction of the drum 200 , the weight layer is provided with at least two weight compartments 20 . By adjusting the distribution of the counterweights 40 in the axial direction of the drum 200, the position of the center of gravity of the counterweight box in the axial direction of the drum 200 can be adjusted, thereby adjusting the force exerted by the counterweight system on the drum 200. tension. Preferably, please refer to figure 2 , the two ends of the counterweight box are respectively suspended and connected to the two ends of th...

Embodiment 3

[0064] The invention provides a method for correcting the belt deviation of a belt conveyor, using the above-mentioned counterweight system of the belt conveyor, such as Figure 9 As shown, the belt deviation correction method includes:

[0065] Step S10, confirming the deviation direction of the belt;

[0066] Step S20, adjusting the distribution positions of the counterweights in the counterweight layer, so that the overall center of gravity of the counterweight box and the counterweights moves along the deviation direction.

[0067] Such as Figure 10 As shown, in some cases, the distribution of the counterweights 40 in the counterweight box is biased to one end, so that the center of gravity of the counterweight box is biased to one end, and the force on both ends of the drum 200 is unbalanced, causing the belt 300 to deviate. Such as Figure 11 As shown, in other cases, the belt 300 will deviate on the roller 200 due to problems such as processing and assembly of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com