Petrochemical RO concentrated brine treatment system and method thereof

A petrochemical and treatment system technology, applied in the field of concentrated brine treatment, to achieve the effects of convenient operation, meeting the demand for dissolved oxygen, and convenient cost

Pending Publication Date: 2020-02-18

北京翰祺环境技术有限公司

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the TN concentration in the effluent of the monitoring pool of the concentrated brine discharge facility has gradually decreased to less than 30 mg/L after the renovation of the biochemical section is completed, it is

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

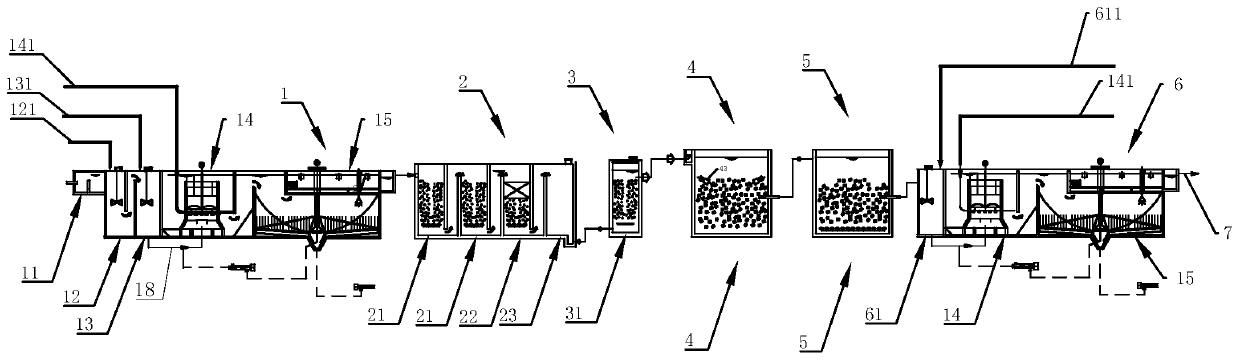

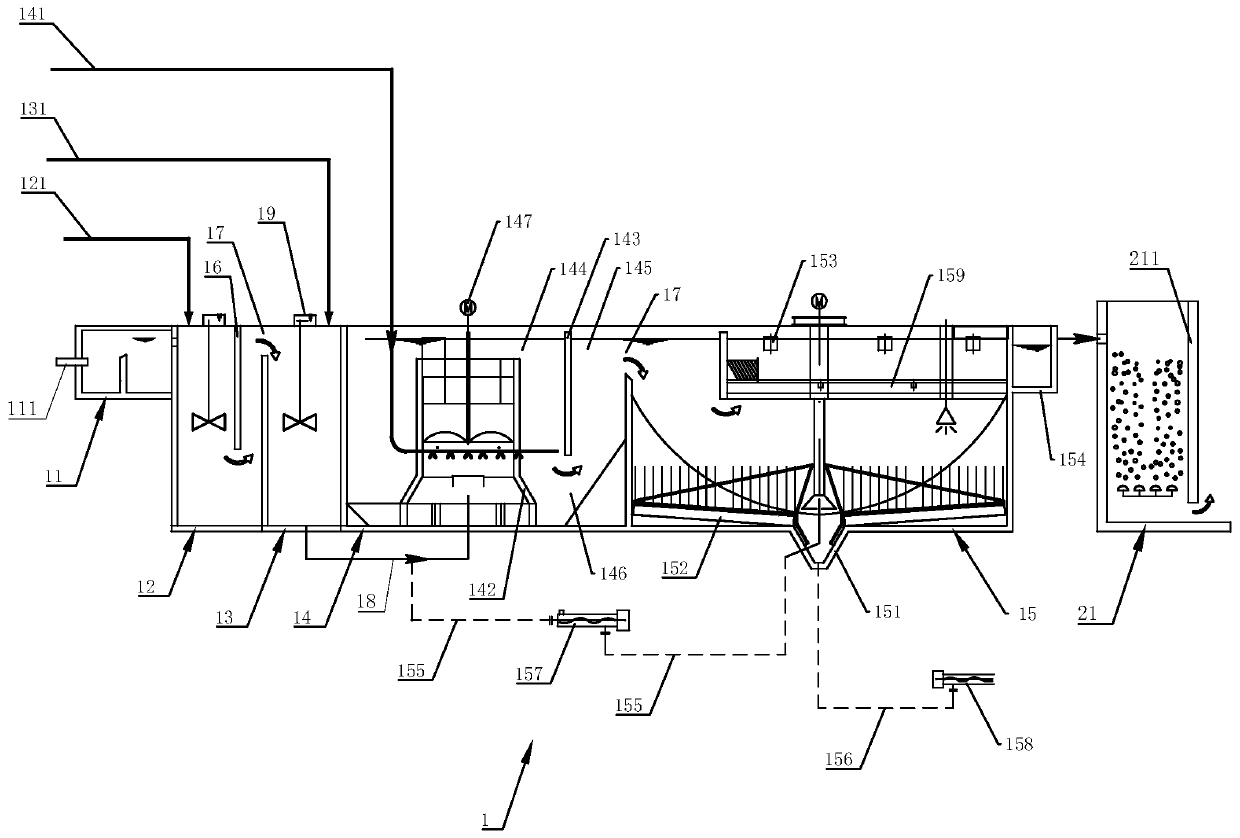

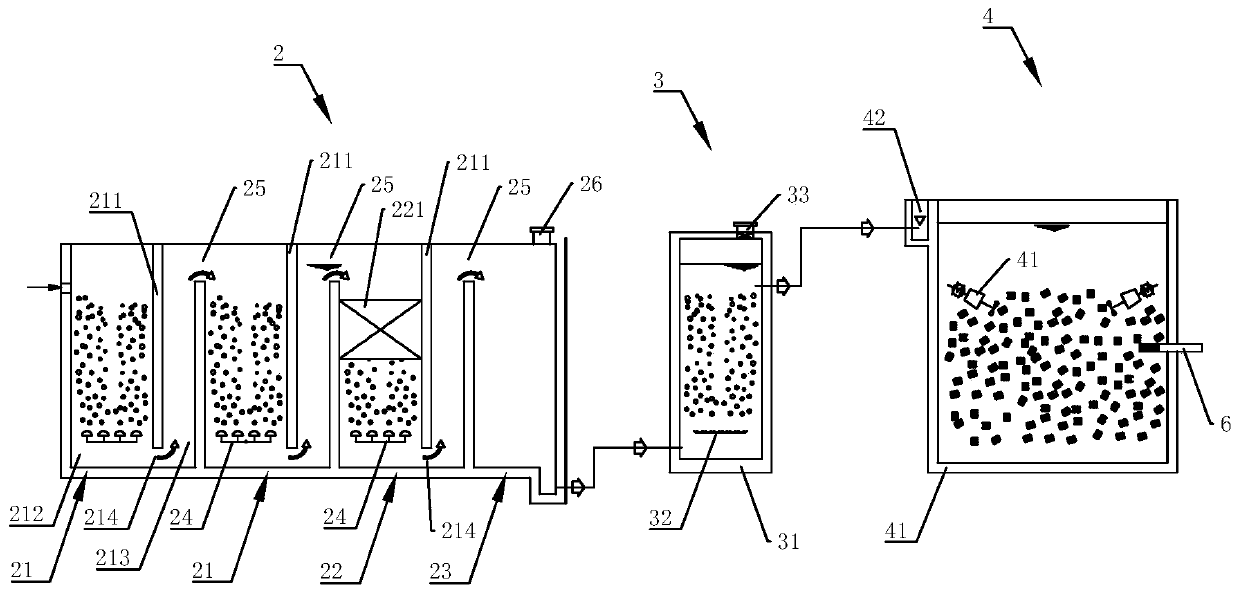

The invention relates to a petrochemical RO concentrated brine treatment system and a method thereof. The system comprises a first high-efficiency precipitation unit, an ozone catalytic oxidation unit, a blowing-off unit, a denitrification unit, an MBBR aerobic unit and a second high-efficiency precipitation unit which are sequentially communicated along the flow direction of concentrated brine, the first high-efficiency precipitation unit is used for removing hard and suspended substances, and the second high-efficiency precipitation unit is used for removing phosphorus and substances, the first high-efficiency precipitation unit is connected with a water inlet pipe, the second high-efficiency precipitation unit is connected with a first water outlet pipe, and the blowing-off unit comprises a blowing-off tank, wherein a blowing-off piece for introducing nitrogen into the concentrated brine in the blowing-off tank is arranged in the blowing-off tank; the treatment method comprises: hard substance removal, coagulation, flocculation, precipitation separation, ozone oxidation, nitrogen stripping, MBBR treatment and phosphorus removal and precipitation. The petrochemical RO concentrated brine treatment system has the advantages that the RO concentrated brine can be treated, COD, total phosphorus, hardness, alkalinity and total nitrogen in the RO concentrated brine are reduced, so that the RO concentrated brine can be discharged up to standard, especially nitrate nitrogen in the concentrated brine can be obviously reduced, and the total nitrogen in the discharged concentrated brine is less than or equal to 10 mg/L.

Description

technical field [0001] The invention relates to the technical field of concentrated brine treatment, in particular to a petrochemical RO concentrated brine treatment system and a method thereof. Background technique [0002] At present, RO treatment technology has been widely used in many fields such as electronics, chemical industry, and seawater desalination, and has irreplaceable advantages. Using RO technology to treat concentrated brine and wastewater will produce about 1 / 3 of concentrated brine, which contains mostly harmful The concentration of refractory biodegradable organic substances in a healthy and ecological environment exceeds the discharge standard, so the treatment of concentrated brine has become a hot spot for the widespread use of RO. [0003] Especially petrochemical RO concentrated brine has the characteristics of high chloride ions, high COD that is difficult to degrade, total nitrogen (mainly nitrate nitrogen, less ammonia nitrogen), total phosphorus,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/14

CPCC02F9/00C02F5/02C02F1/5281C02F1/78C02F1/725C02F1/20C02F3/302C02F1/58C02F1/283C02F1/001C02F2209/08C02F2209/055C02F2209/07C02F2209/16C02F2209/10

Inventor 王晓阳巨春燕汪德罡郝瀚谢晓朋王寿鹤

Owner 北京翰祺环境技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com