Method for preparing antifouling curtain by inorganic foaming finishing

An inorganic foaming and anti-fouling technology, which is applied to window decorations, anti-coloring and pollution/anti-fouling fibers, curtains, etc., can solve the problem that inorganic particles cannot be directly applied to anti-fouling curtains, etc. Dense, easy-to-wet fabric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

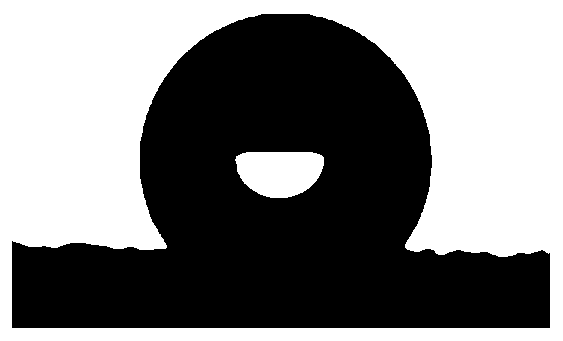

Image

Examples

Embodiment 1

[0040] The preparation method of oxidized nano-carbon black, weighing about 3g of carbon black raw material N234 into a round bottom flask, adding 100mL of hydrogen peroxide, the oxidation process is: treatment in a water bath at 60°C for 8 hours, during the treatment, if no bubbles are released, it means Hydrogen peroxide reacts completely. The reacted mixture needs to settle carbon black, and then pour out the solvent to obtain primary oxidation nano-carbon black; add 100mL hydrogen peroxide to the primary oxidation nano-carbon black, repeat the aforementioned oxidation process twice, then filter the mixture, at 100°C Drying under low temperature to obtain oxidized nano-carbon black.

Embodiment 2

[0042] A method for preparing antifouling curtains by inorganic foaming finishing, the steps are as follows:

[0043] (1) A mixture of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and γ-methacryloxypropyltrimethoxysilane with a mass ratio of 1:1, Fluorine-containing acrylate and diethylenetriamine pretreat the product of Example 1 to obtain modified oxidized nano carbon black. The pretreatment process is: first disperse the oxidized nano carbon black in N- In the aqueous solution of the mixture of (β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and γ-methacryloxypropyltrimethoxysilane, add fluorine-containing acrylate, di Ethylenetriamine is stirred evenly, wherein, the consumption of oxidized nano-carbon black is 6g / L, and the mass ratio is 1:1 of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and The dosage of the mixture of γ-methacryloxypropyltrimethoxysilane is 0.5g / L, the dosage of fluorine-containing acrylate is 10g / L, and the dosage of diethylenetriamine...

Embodiment 3

[0066] A method for preparing antifouling curtains by inorganic foaming finishing, the steps are as follows:

[0067] (1) A mixture of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and γ-methacryloxypropyltrimethoxysilane with a mass ratio of 1:1, FUR-616E and diethylenetriamine on nano-SiO 2 Pretreatment to obtain modified nano-SiO 2 , the pretreatment process is: first nano-SiO 2 Dispersed in an aqueous solution of a mixture of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and γ-methacryloxypropyltrimethoxysilane with a mass ratio of 1:1 , and then add FUR-616E and diethylenetriamine and stir evenly, among them, nano-SiO 2 The dosage is 7g / L, and the mass ratio of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane to γ-methacryloxypropyltrimethoxysilane is 1:1. The dosage of the mixture is 1g / L, the dosage of FUR-616E is 15g / L, the dosage of diethylenetriamine is 3.5g / L; nano-SiO 2 The average particle size is 10nm;

[0068] (2) will be made of modified na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap