An underground sludge pipeline dredging device for building construction

A technology for building construction and land use, which is applied in the direction of cleaning sewer pipes, buildings, water supply devices, etc., and can solve problems such as difficulty in dredging sewage pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

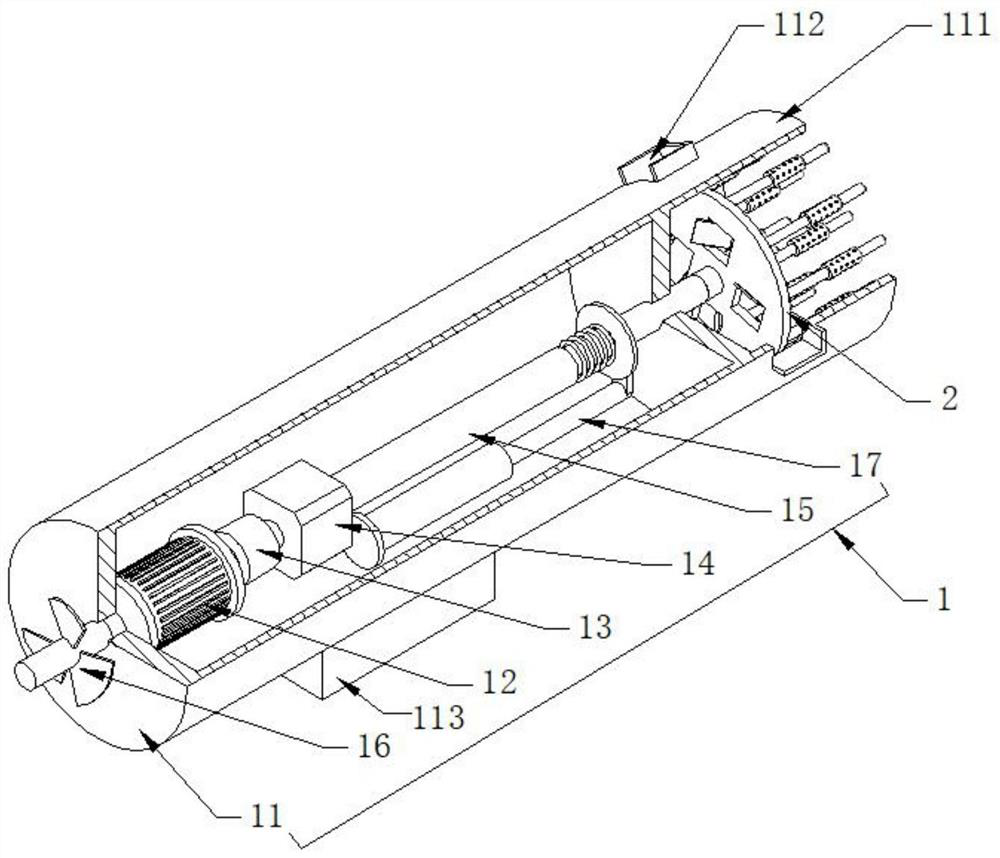

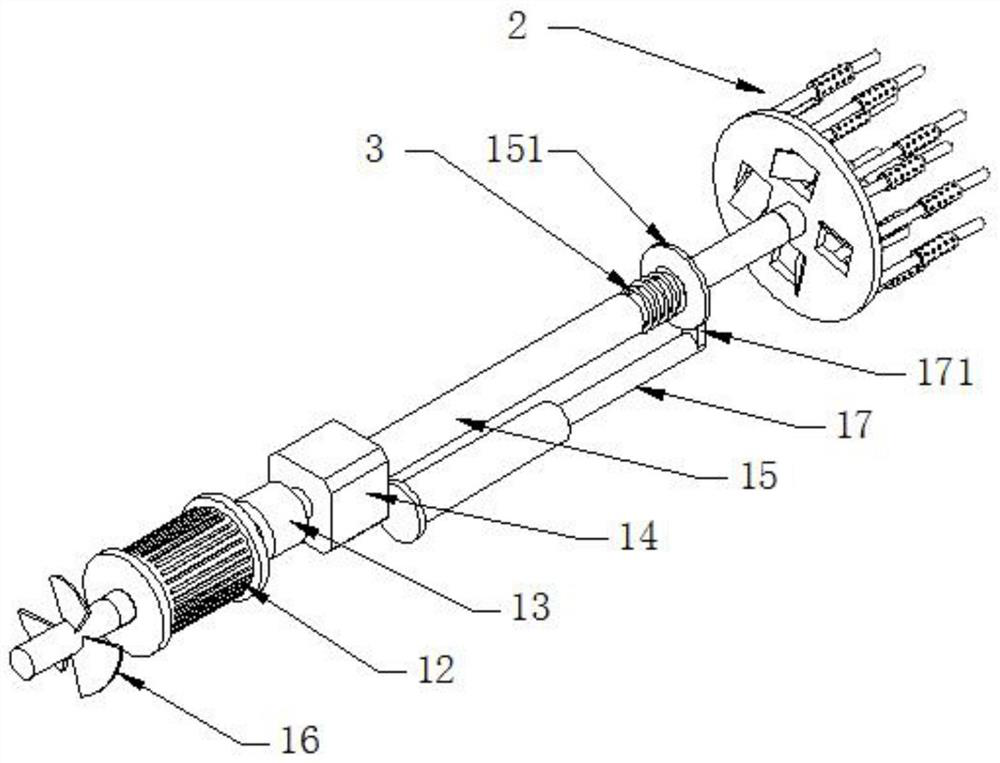

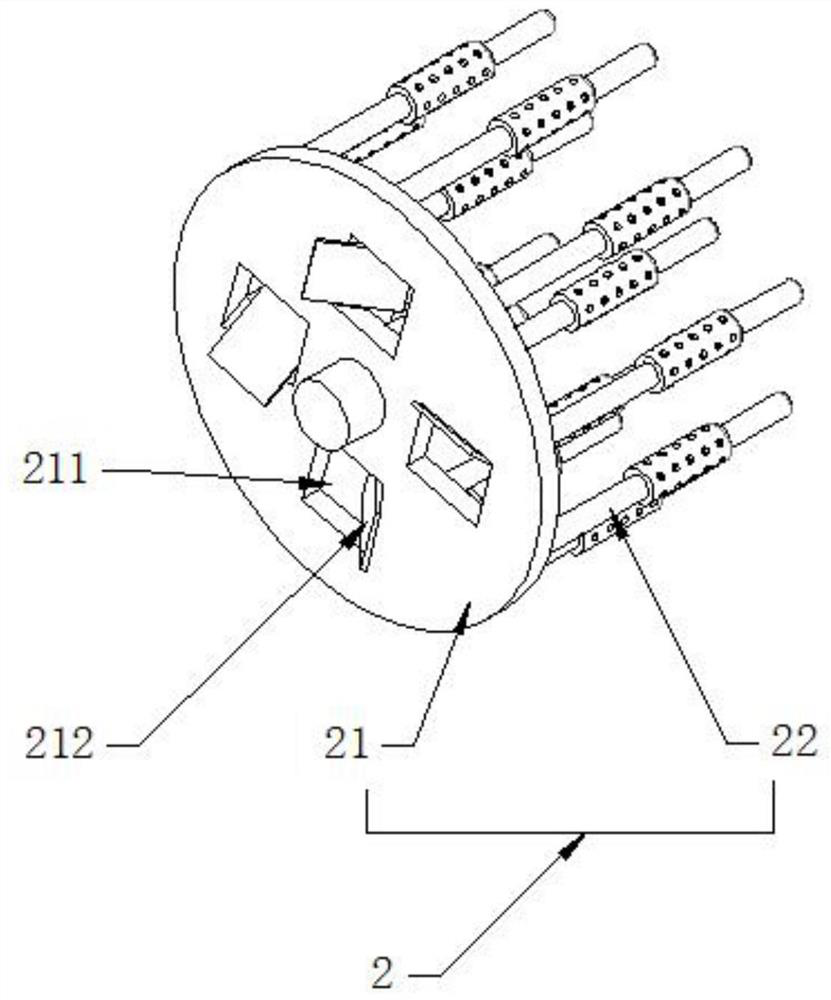

[0037] see Figure 1-5, an underground sludge pipeline dredging device for building construction, comprising a diving part 1 and a loose part 2 arranged at one end of the diving part 1, the diving part 1 includes a diving cylinder 11, a double-head motor 12, an electric clutch 13, and a gear reversing box 14. Telescopic rod 15, cylinder 17 and impeller 16. The impeller 16 is rotated and arranged at one end of the diving tube 11 to provide power for diving and walking. The bottom of the diving tube 11 is fixedly provided with a counterweight box 113. The heavy block is used to adjust the position of the whole diving part 1 in the water. The double-headed motor 12, the electric clutch 13, the gear reversing box 14 and the telescopic rod 15 are all arranged in the diving tube 11 and connected successively along the axial direction. The cylinder 17 is located at Inside the diving tube 11 and its extension shaft is used in conjunction with the action shaft of the telescopic rod 15....

Embodiment 2

[0039] see figure 2 The difference from Embodiment 1 is that the spring 3 is sleeved on the action shaft and on one side of the limit ring plate 151, the traction plate 171 is located on the other side of the limit ring plate 151, and the traction plate 171 is located far away from the spring 3 On one side, when the action shaft shrinks, the spring 3 is in a compressed state. With this structure, after the cylinder 17 is released, the action shaft will protrude outward under the action of the spring 3, and then drive the entire loose part 2 to protrude quickly. The protective limit sleeve 111 and the insertion shaft 2222 on the loose part 2 are inserted into the blockage, and the elastic buffering effect of the spring 3 effectively protects the loose part 2 .

Embodiment 3

[0041] see Figure 4 The difference from Embodiment 1 is that the evaporation part 223 includes a tungsten shaft 2231 located inside and a ceramic sleeve 2232 sleeved outside the tungsten shaft 2231. The ceramic sleeve 2232 and the injection sleeve 222 have a clearance fit, and the tungsten shaft 2231 adopts a metal tungsten shaft 2231. The material has the effect of high temperature resistance. The ceramic sleeve 2232 has good thermal conductivity and can also protect the tungsten shaft 2231.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com