An intelligent sliding sleeve of multi-stage fracturing electric control switch without bridge plug

A technology of intelligent sliding sleeve and electronically controlled switch, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve problems such as complex construction operations, and achieve the effect of improving fracturing operation efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

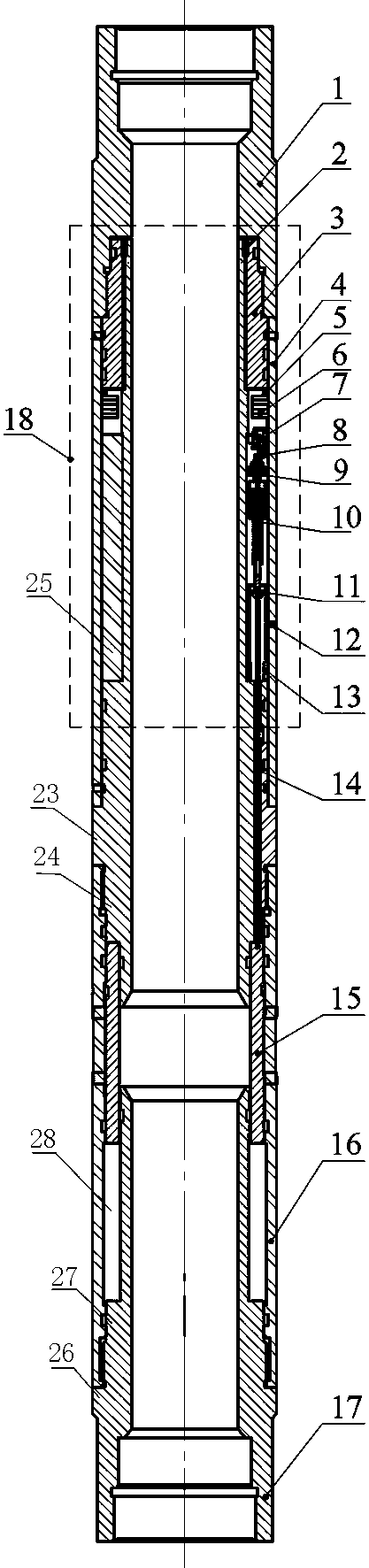

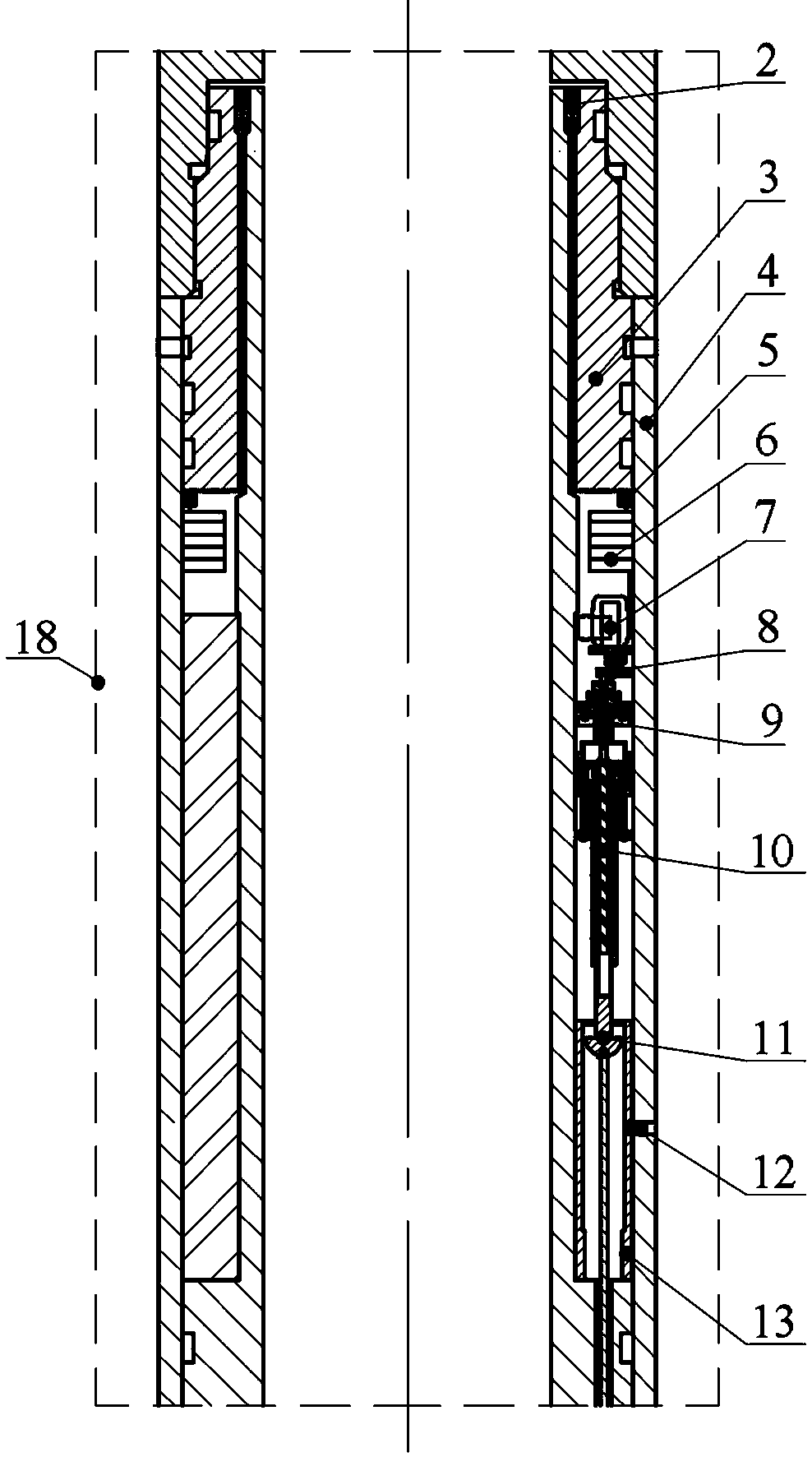

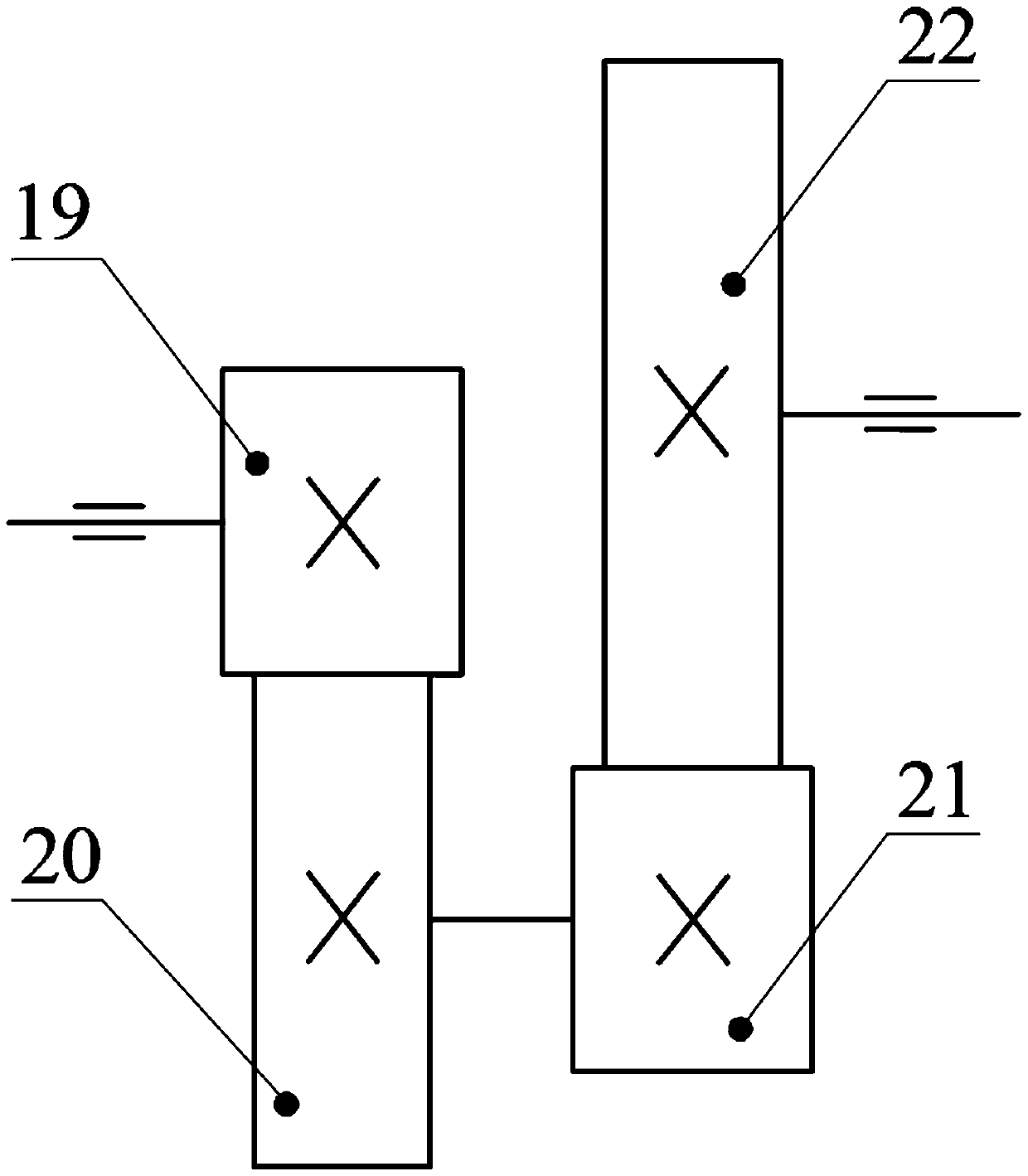

[0023] like figure 1 As shown, a non-bridge plug multi-stage fracturing electronically controlled switch intelligent sliding sleeve includes an upper joint 1, an inner cylinder 3, an outer cylinder 4, a piston 15, a fracturing sleeve 16, a lower joint 17 and a control system 18; The lower end of the upper joint 1 is threadedly connected to the upper end of the inner cylinder 3, the outer cylinder 4 is fixed to the outside of the inner cylinder 3 through threads, the upper end of the fracturing sleeve 16 is threadedly connected to the lower end of the inner cylinder 3, and the lower end of the fracturing sleeve 16 is It is threadedly connected with the upper end of the lower joint 17, the middle part of the inner cylinder 3 is provided with a first step 23, the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com