Dynamic weighing detection device with self-learning function

A technology of dynamic weighing and detection devices, which is applied in the field of product packaging production, can solve problems such as the failure to update the working mode and parameters in time, the shutdown of the production line, and complicated working conditions, so as to reduce frequent manual adjustment interventions, prolong service life, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

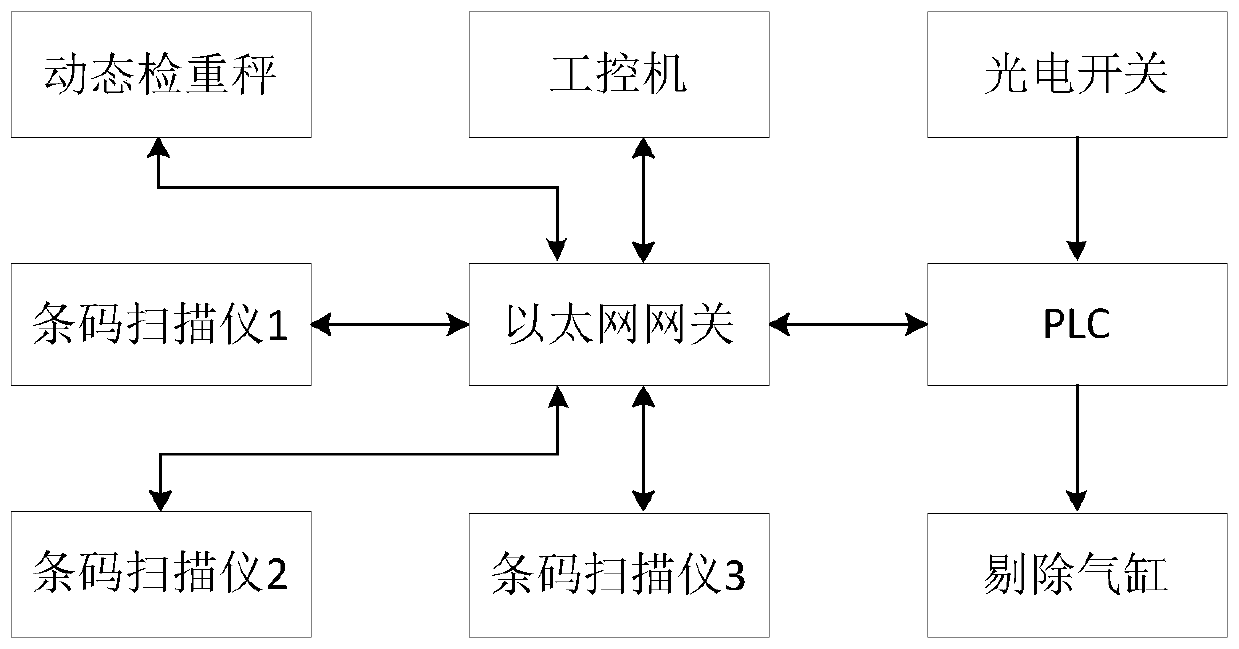

[0022] Such as figure 1 As shown, a dynamic weighing detection device with self-learning function includes dynamic checkweigher, industrial computer, programmable logic controller and several barcode scanners, dynamic checkweigher, industrial computer, programmable logic controller and The barcode scanner communicates with each other through the Ethernet gateway, the digital input port of the programmable logic controller is connected with the entrance photoelectric switch signal, and the digital output port is connected with the rejection cylinder.

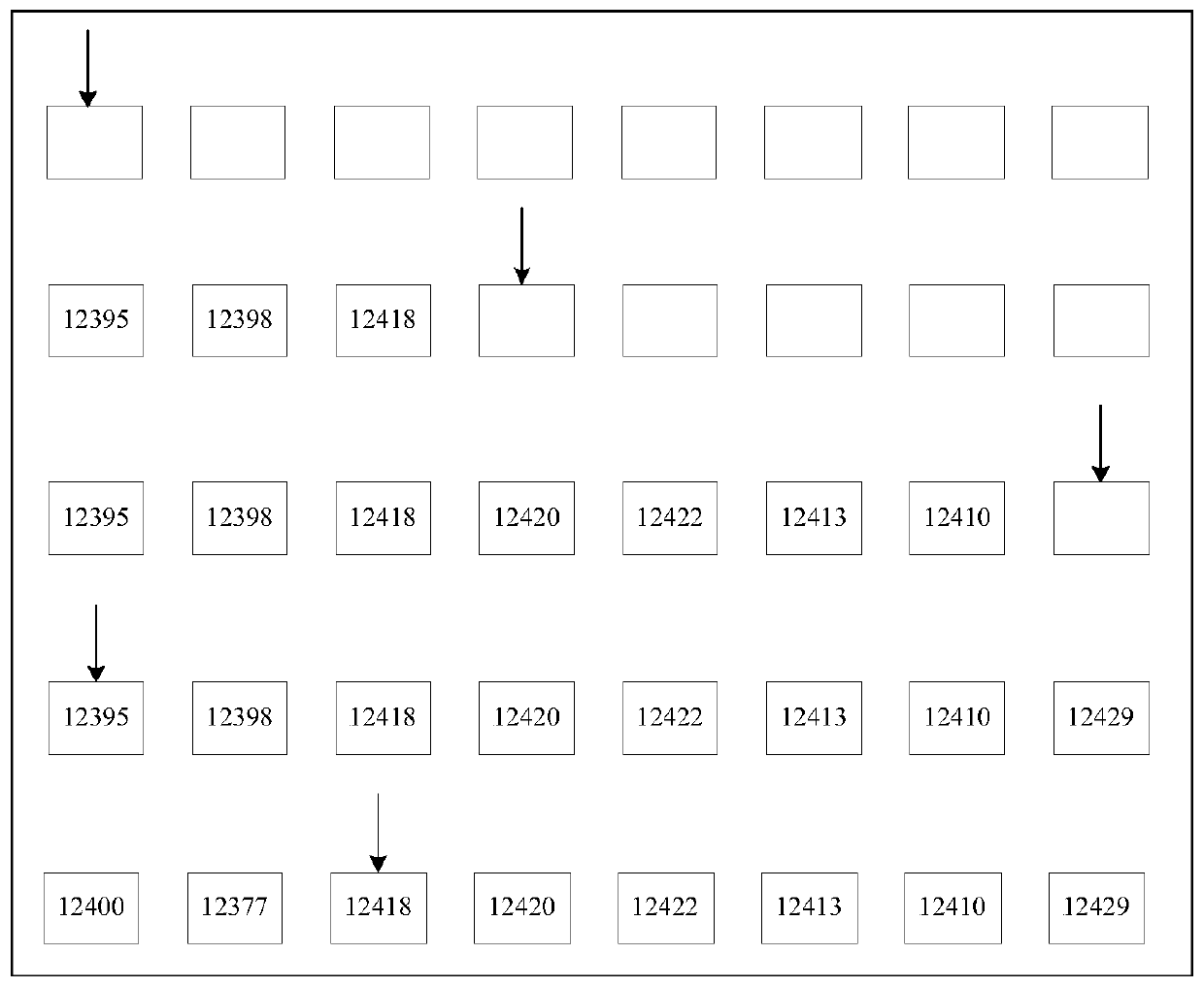

[0023] The device is installed on the product conveying line. When the product on the product conveying line passes through the device, two barcode scanners scan the project code and box code at the same time. When both barcodes can be scanned, the working mode is set to carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com