Method for fast evaluating dispersibility of gasification ash water dirt dispersion agent

A scale-inhibiting dispersant, gray water technology, applied in the direction of analysis of materials, instruments, etc., can solve the problem that the evaluation of the dispersing ability of the agent cannot be achieved, and achieve the effect of objective and accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

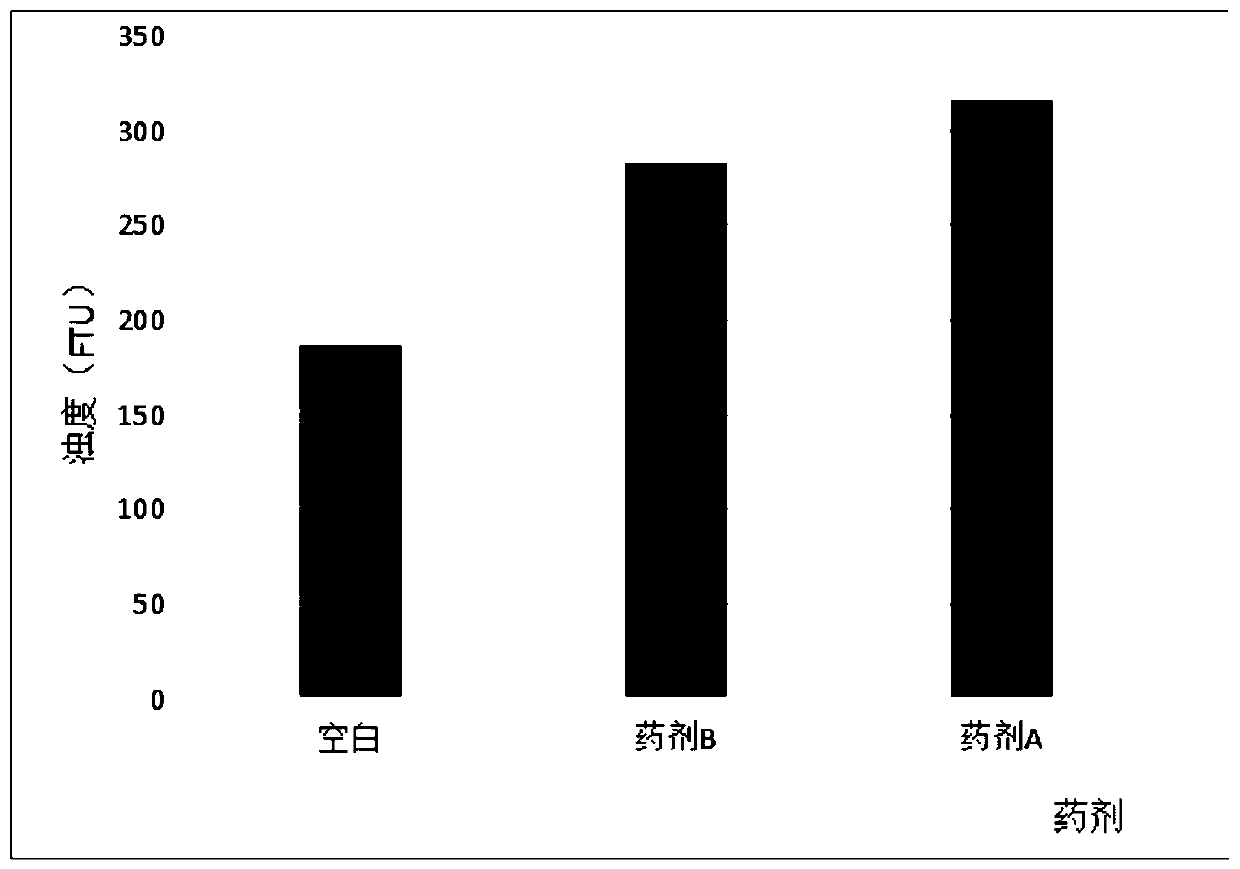

[0041] Example 1 A method for quickly evaluating the dispersibility of gasified gray water scale inhibitors and dispersants of the present invention is used to compare and evaluate the medicaments. The case is as follows:

[0042] 1) Coal ash particle size adjustment: adjust the fired coal ash particle size so that its particle size distribution matches the fine ash particle size distribution in black water. The particle size distribution of the suspension coal ash is shown in Table 1:

[0043] Table 1 Coal ash particle size distribution data table

[0044] <10%

<25%

<50%

<75%

<90%

4.242μm 12.20μm 27.12μm 49.51μm 60.61μm

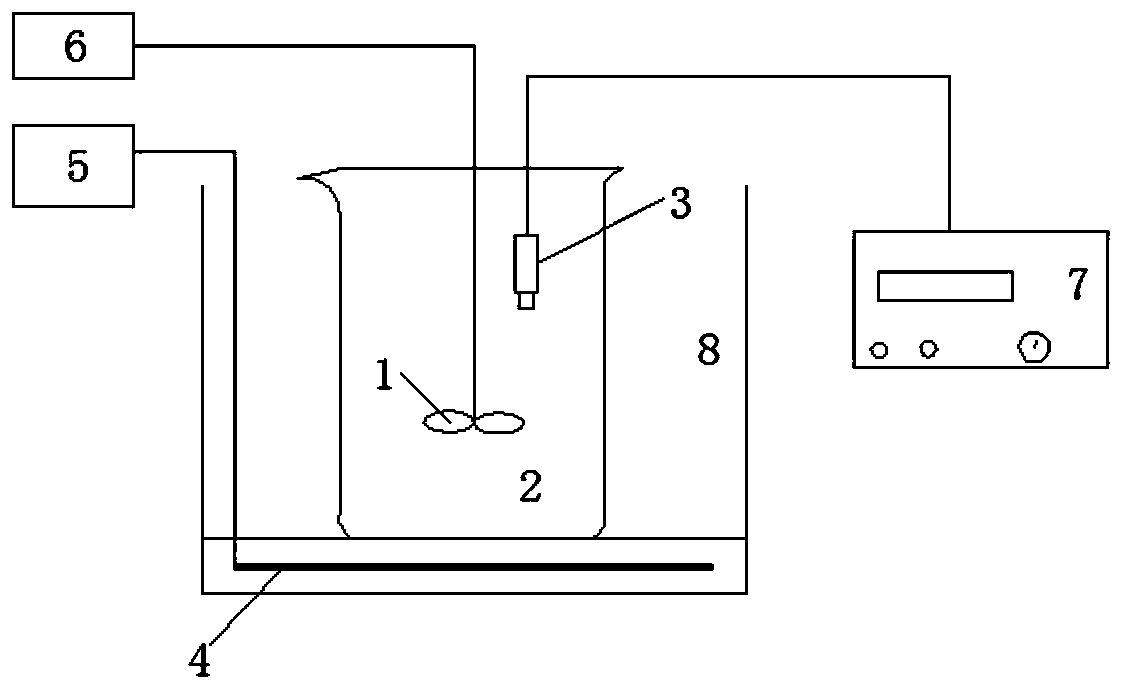

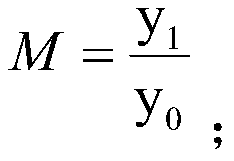

[0045] 2) Configure experimental water: weigh 5g of prepared coal ash particles and pour them into a beaker, then add 500ml of water into the experimental beaker to ensure that the solid content of the prepared suspension is 1%, and put the prepared suspension solution into the water bath Heating in the pot at a constan...

Embodiment 2

[0058] Example 2 A method for quickly evaluating the dispersibility of gasified gray water scale inhibitors and dispersants of the present invention is used to compare and evaluate the medicaments. The case is as follows:

[0059] 1) Coal ash particle size adjustment: adjust the fired coal ash particle size so that its particle size distribution matches the fine ash particle size distribution in black water. The particle size distribution of the suspension coal ash is shown in Table 5:

[0060] Table 5 coal ash particle size distribution data table

[0061] <10%

<25%

<50%

<75%

<90%

5.695 13.56 35.52 74.08 160.6

[0062] 2) Configure experimental water: weigh 5g of prepared coal ash particles and pour them into a beaker, then add 500ml of water into the experimental beaker to ensure that the solid content of the prepared suspension is 1%, and put the prepared suspension solution into the water bath Heating in the pot at a constant temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com