A method for testing the heat transfer performance of lubricating grease for rv reducers

A technology of heat transfer performance and testing method, applied in the field of testing the heat transfer performance of grease for RV reducer, can solve the problem of not involving the evaluation of heat transfer performance of RV reducer grease, the test method is not scientific and rigorous, affecting the RV reducer, etc. To achieve the effect of convincing evaluation results, simple test results and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

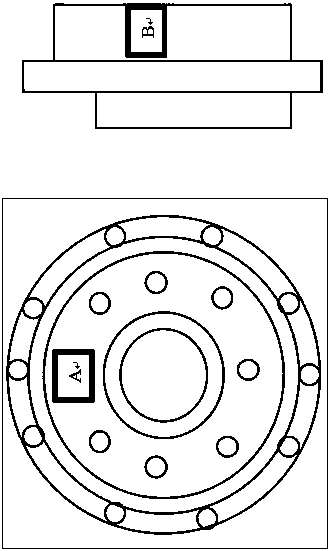

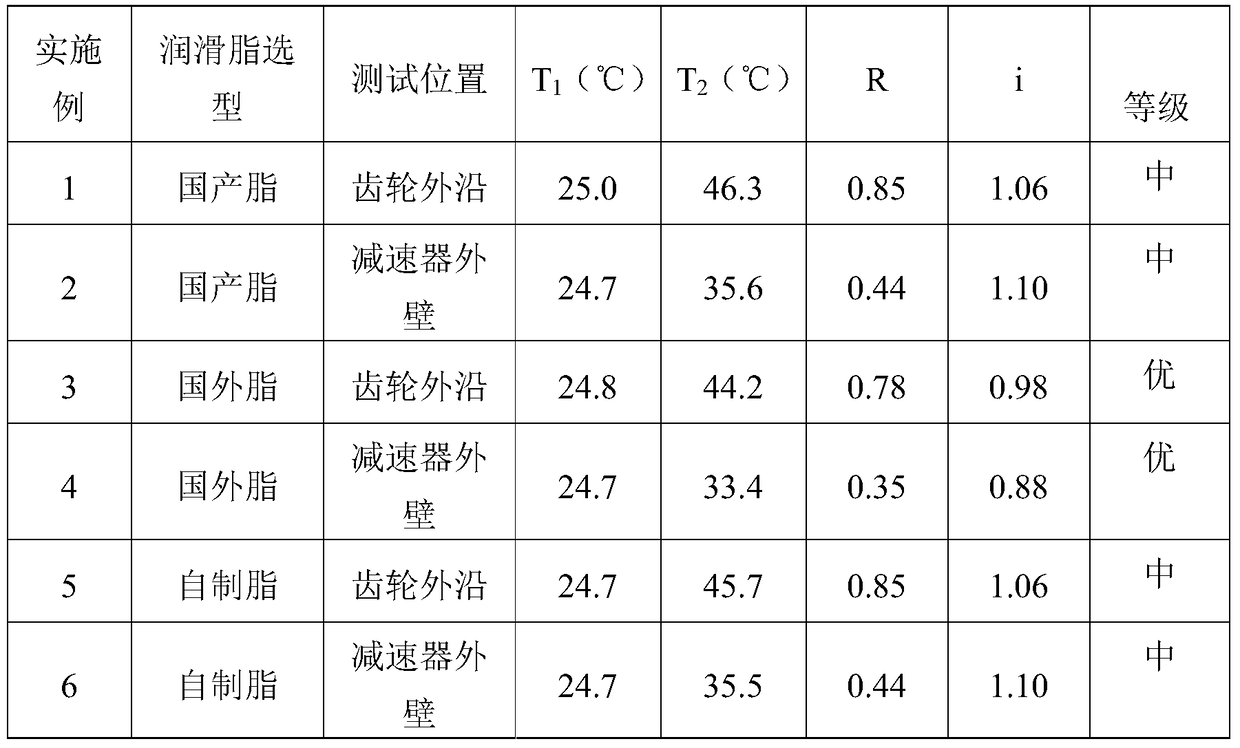

[0026] According to the grease selected in Table 1, apply the grease to be tested to a certain type of RV reducer, and use a temperature tester to test the temperature of the outer wall of the RV reducer and the temperature of the outer edge of the gear of the RV reducer after installation. Selected from the outer edge of RV reducer gear (such as figure 1 middle point A) or the outer wall of the reducer (such as figure 1 Point B) in a certain position, the test results are analyzed by temperature distribution processing software, and the average temperature T of the test surface is calculated 1 . After running for 24 hours, stop running, use temperature testing equipment to test the temperature of the same position above, and analyze the test results with temperature distribution processing software to calculate the average temperature T of the test surface 2 , according to R=(T 2 -T 1 ) / T 1 ;i=R / R T , according to the range of the value of i, evaluate the heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com