Automatic scheduling method and system for non-standard manufacturing process

A manufacturing process and automatic arrangement technology, applied in the field of non-standard parts manufacturing, can solve the problems of improving the full utilization of production equipment, low production planning efficiency, unfavorable production efficiency, etc., and achieve the effect of reasonable production planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

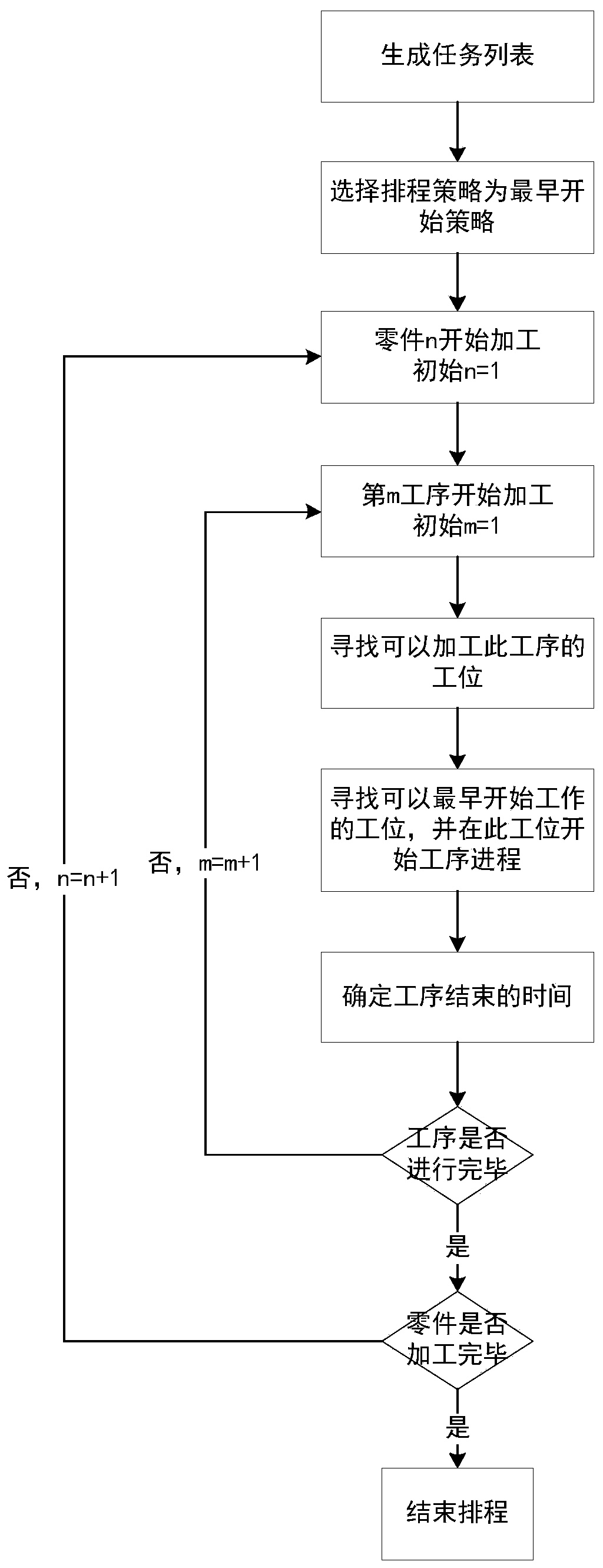

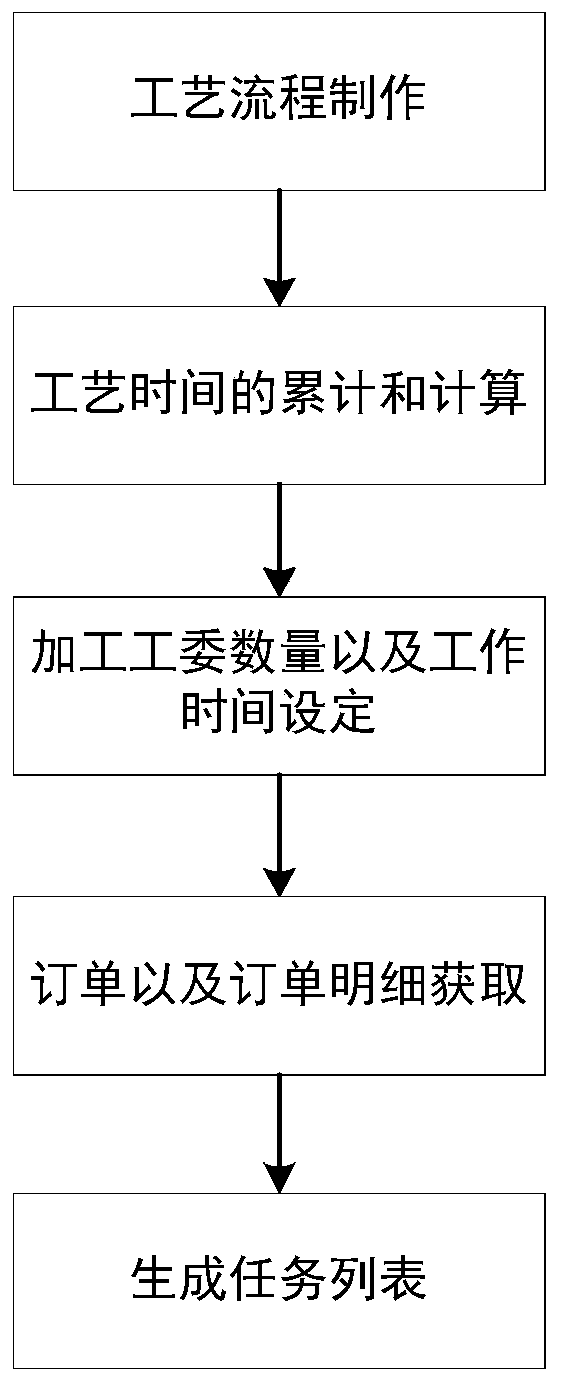

[0040] figure 1 It is the flow chart of embodiment 1. Such as figure 1 As shown, Embodiment 1 is an automatic scheduling method for non-standard manufacturing processes, specifically including:

[0041] S101. Generate a task list. The task list includes the machining sequence of multiple parts and the machining operation of each part.

[0042] S102. Select a scheduling strategy. The scheduling strategy in Embodiment 1 is the earliest start strategy. After each station finishes processing the last part, there will be free time, and the station with free time can plan a new start time. The earliest start strategy is to select the workstation that can perform this process for each process, sort the selectable workstations forward according to the free time, and select the workstation with the earliest planned start time.

[0043] S103. The nth part starts to process. n=1,2,3,...,N. The initial value of n is 1.

[0044] S104. The mth process starts. m=1,2,3,...,M. The i...

Embodiment 2

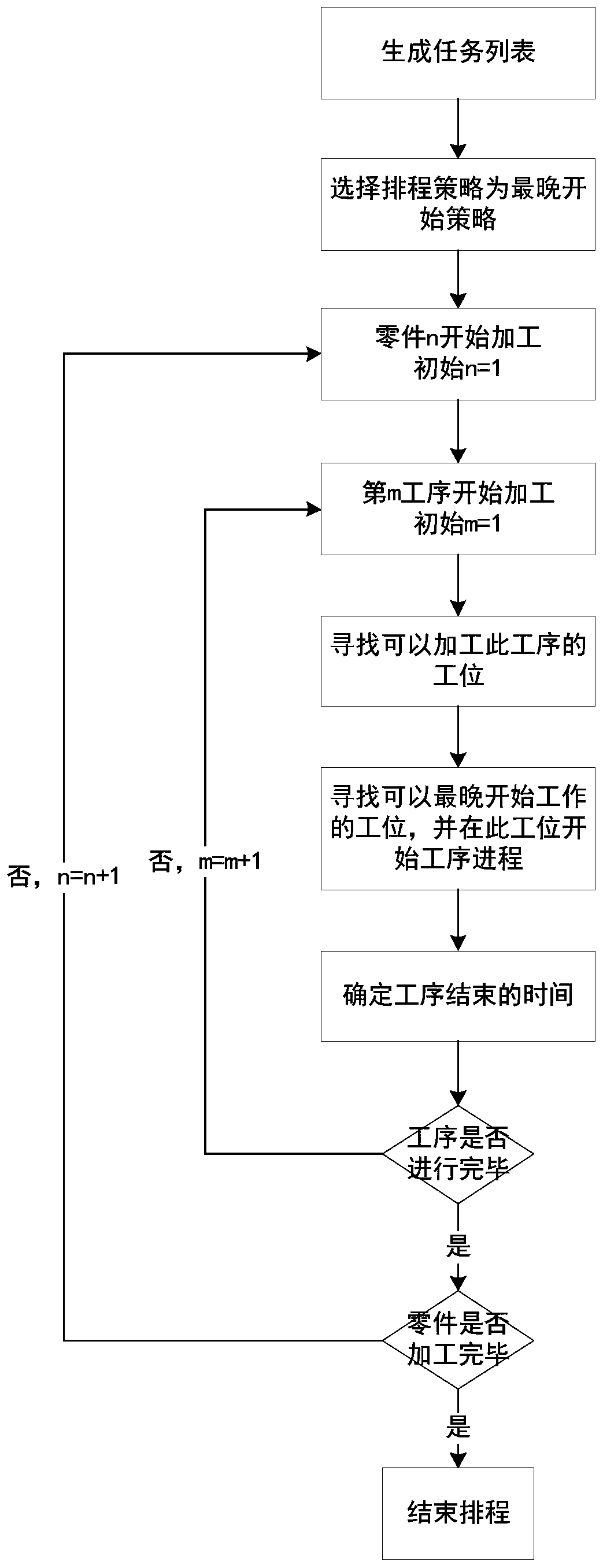

[0051] figure 2 It is the flowchart of embodiment 2. Such as figure 2 As shown, the automatic scheduling method for non-standard manufacturing process in Embodiment 2 specifically includes:

[0052] S201. Generate a task list. The task list includes the machining sequence of multiple parts and the machining operation of each part.

[0053] S202. Select a scheduling strategy. The scheduling strategy in embodiment 2 is the latest start strategy. Delivery days vary for each order. The latest start strategy is to sort in reverse according to the delivery date of the order, that is, the delivery date of the parts in the order. The part with the latest delivery time is the first in the task list, but it needs to be arranged later when selecting a station . When selecting a processing station that can perform this process for each process, the selectable stations are reversely sorted according to the earliest free time, and the station with the latest planned start time is s...

Embodiment 3

[0062] Steps S301 to S309 in Embodiment 3 are the same as Steps S101 to S109 in Embodiment 1, and further, Step S300 is also included before Step 301 .

[0063] S300. Task scheduling. In the task scheduling step, all parts in all orders are sorted according to weights, and the processing sequence of multiple parts is determined. Weights can include part lead times and machining priorities. It can also be other factors that need to be considered in production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com