A control method and system for manufacturing powder raw materials based on mes system

A manufacturing control and raw material technology, applied in the field of powder raw material manufacturing control method and system based on MES system, can solve the problems of increasing labor cost input, difficulty in hiring workers, harsh production environment, etc. Agile production, performance and quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

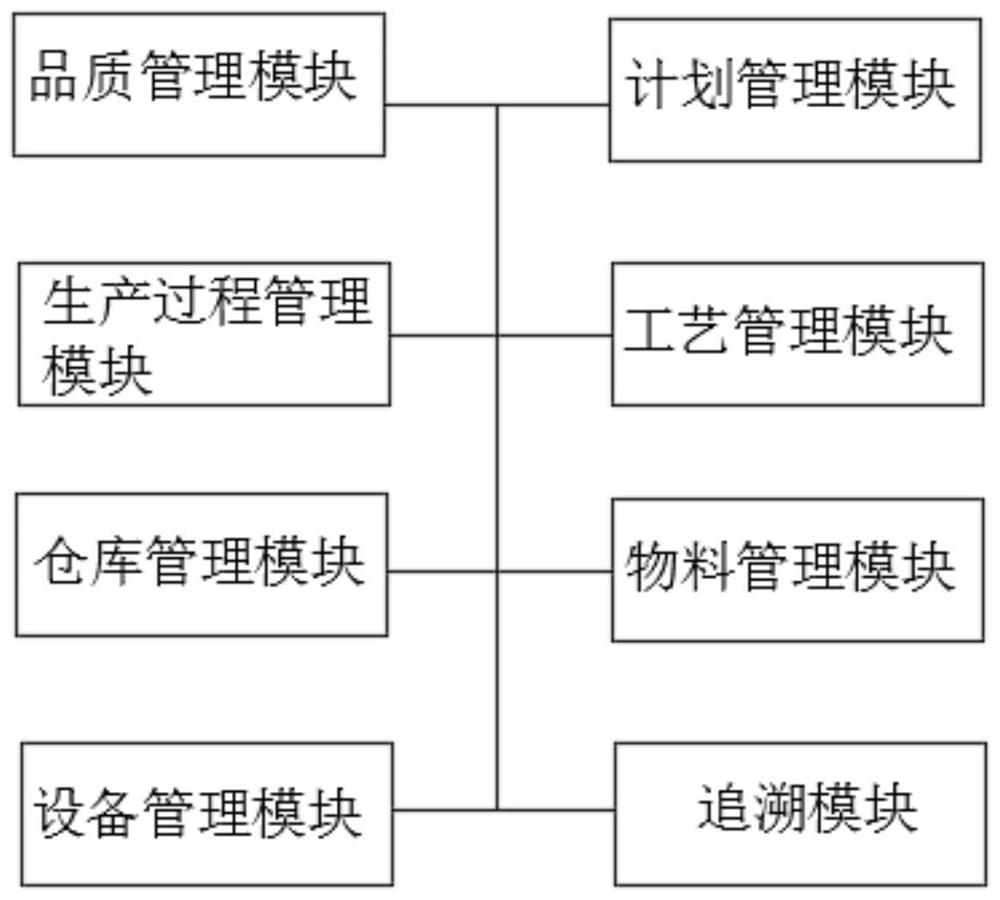

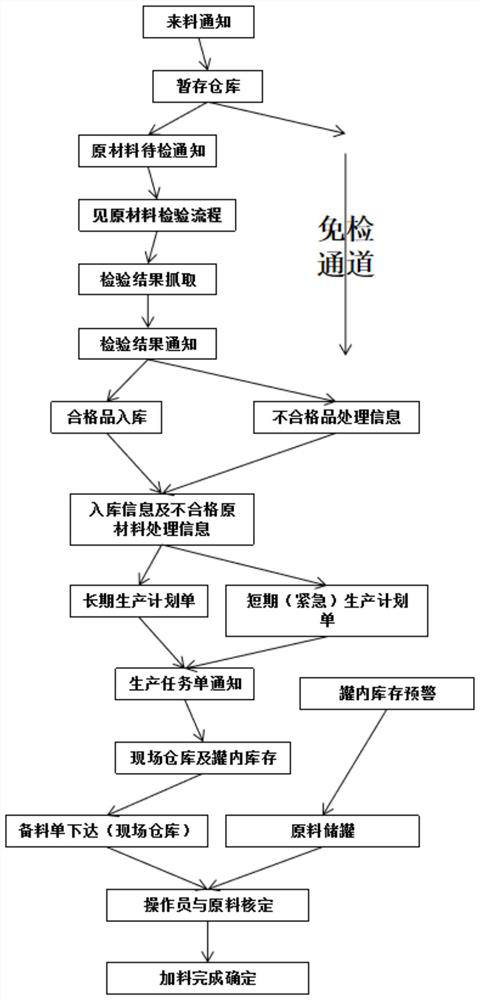

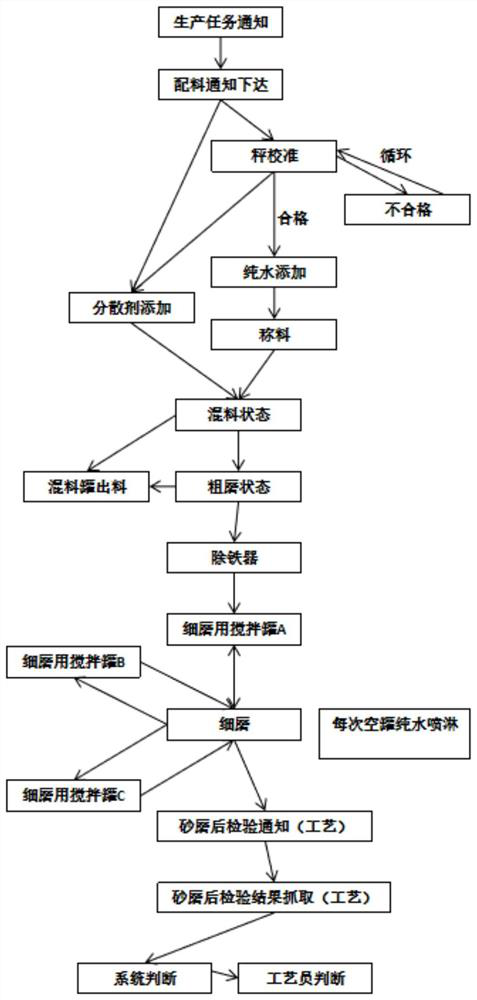

[0040] Such as Figure 1-8 As shown, a powder raw material manufacturing control method based on MES system, including quality management module, plan management module, production process management module, process management module, warehouse management module, material management module, equipment management module and traceability module, control The method includes the following steps:

[0041] S1. The quality management module manages the quality inspection process of materials;

[0042] S2. The planning management module schedules the production materials and production equipment according to the production and processing process units;

[0043] S3. The production process management module controls the manual input data and equipment operation data in the production and processing process through the MES system;

[0044] S4. The process management module manages the operating parameters of the production process equipment and captures the operating data of the productio...

Embodiment 2

[0074] Such as Figure 1-8 As shown, a powder raw material manufacturing control system based on MES system in Embodiment 1 includes quality management module, plan management module, production process management module, process management module, warehouse management module, material management module, equipment management module and traceability Modules, quality management module, plan management module, production process management module, process management module, warehouse management module, material management module, equipment management module, and traceability module work together, and the quality management module is used to manage the quality inspection process of materials; The plan management module is used to schedule production materials and production equipment according to the production and processing process units; the production process management module is used to control the manual input data and equipment operation data in the production and processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com