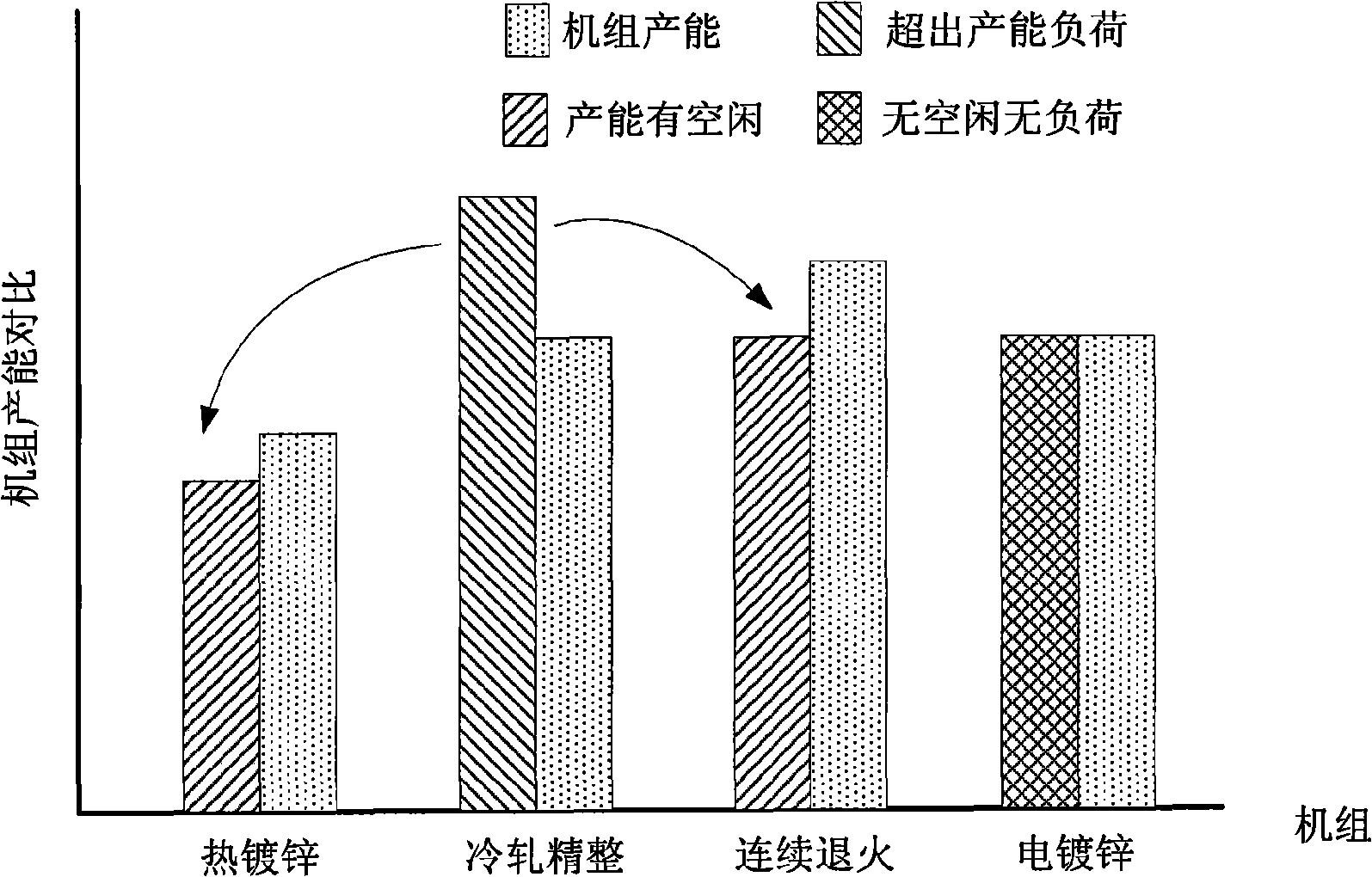

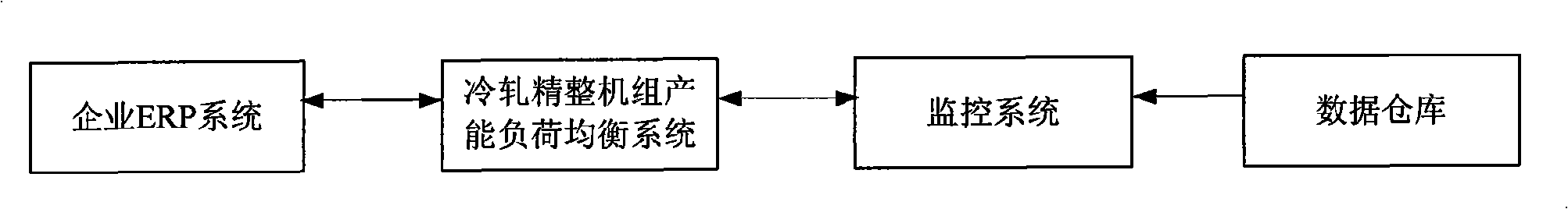

Productivity load equalization method for cold rolling final finishing units of steel enterprise

A finishing unit and load balancing technology, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of complicated factors, insufficient prediction, and inaccurate judgment of production capacity and load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

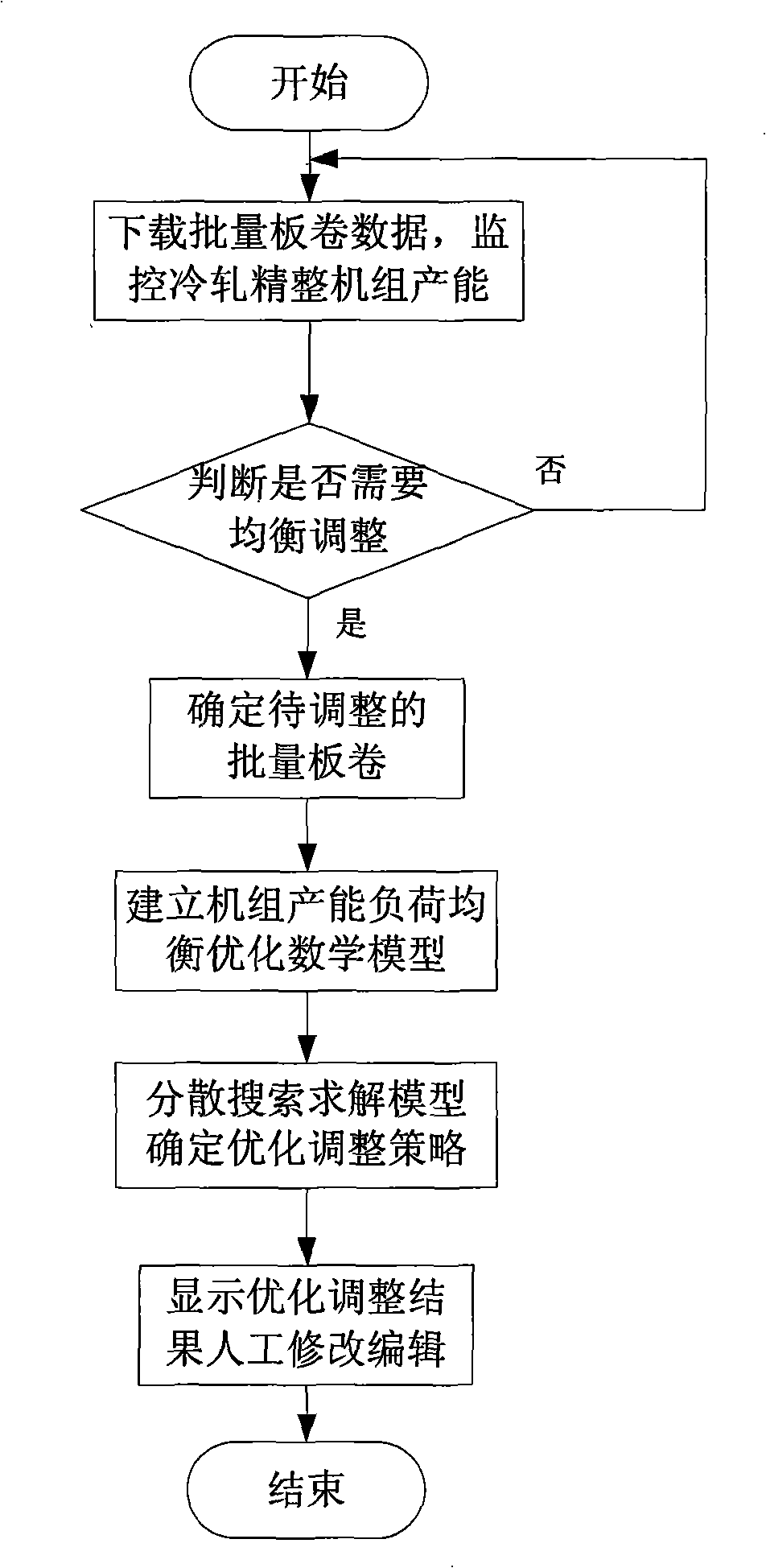

[0082] By testing the production contract data of a cold rolling finishing unit in a large iron and steel enterprise from June 7 to 22, 2007, the specific method steps are as follows:

[0083] Step 1: Establish an initial population of 100 solutions according to the heuristic method. This heuristic method combines greedy and random strategies, that is, first randomly selects a contract to be adjusted, calculates the objective function value of the contract produced by each unit, selects the unit with the largest objective function value, and then randomly selects another contract to repeat Until all the contracts to be adjusted select production units, an initial solution is obtained. After obtaining an initial solution through the above heuristic, randomly select a contract again, and then obtain a solution according to the heuristic method, so as to obtain the required initial population of 100 solutions in turn.

[0084] The second step: the quality of the solutions in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com