Thin seam working face coal mining adaptability evaluation method

A technology for adaptability evaluation and working face, applied in data processing applications, instruments, calculations, etc., can solve the problems of substandard actual production capacity, unreasonable production capacity prediction, roof and floor adaptability, inclination angle adaptability, control method, and personnel technical level , mine management level impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

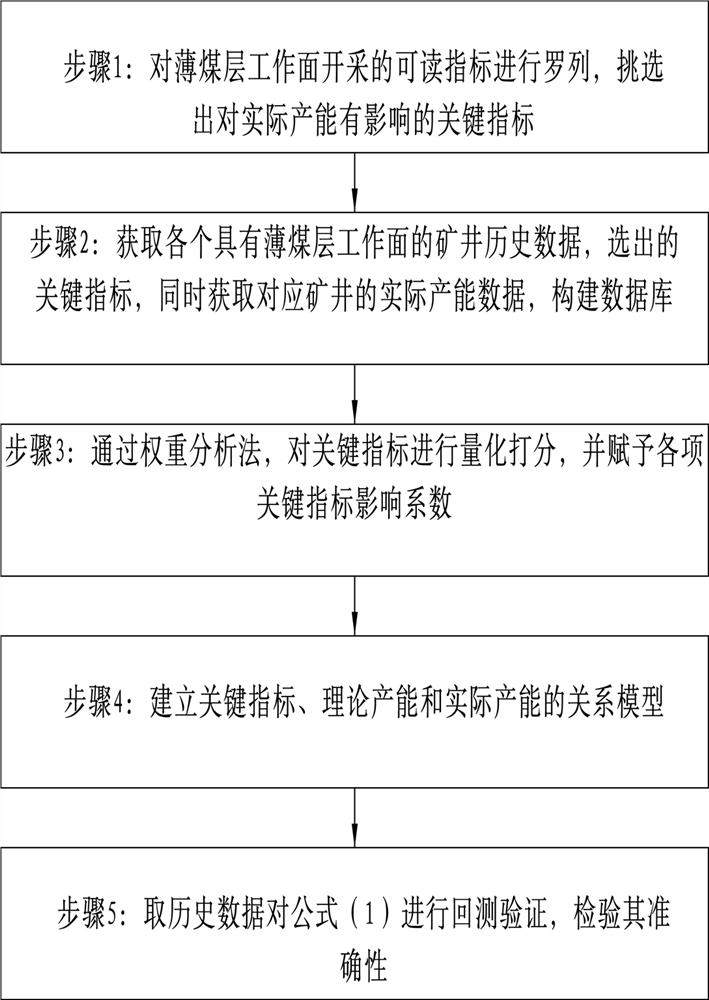

[0041] Such as figure 1 As shown, a thin coal seam mining adaptability evaluation method includes the following steps:

[0042]Step 1) List the readable indicators of thin coal seam mining, and select key indicators that have an impact on actual production capacity, including support strength adaptability, mining height adaptability, support strength adaptability, and working face inclination angle adaptability , Adaptability to inclination angle, roof adaptability, adaptability to roadway layout, control method, cleanliness control, power supply, liquid, water method, belt, lifting system, advanced support method, mining method, personnel technical level, mine management level The determination of these key indicators first selects directly related indicators through objective factors, and the remaining indicators are determined by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com