A method, device, equipment and storage medium for predicting production capacity of an assembly production line

A technology for assembly production line and production capacity forecasting, applied in forecasting, data processing applications, instruments, etc., can solve problems such as the inability to accurately predict the production line capacity of aircraft production lines, and achieve the effect of improving accuracy and accurate production capacity forecasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

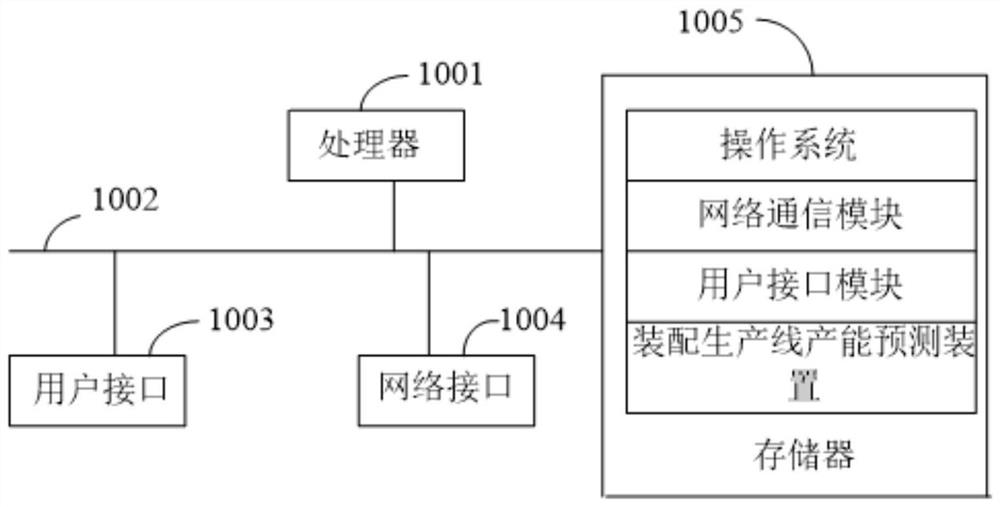

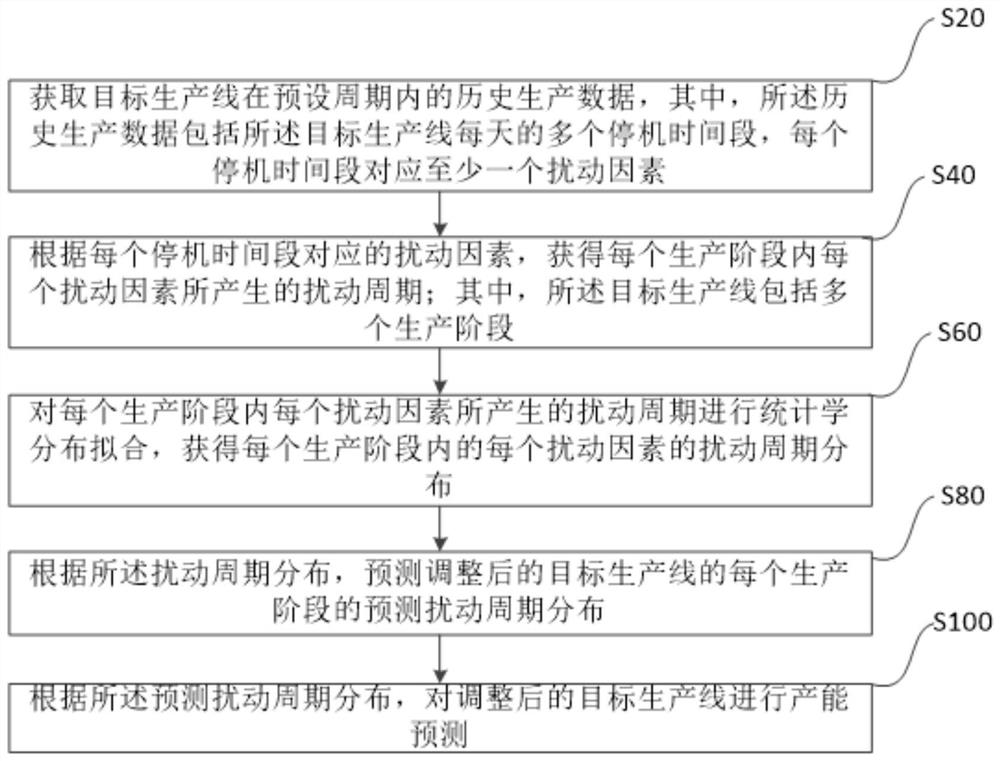

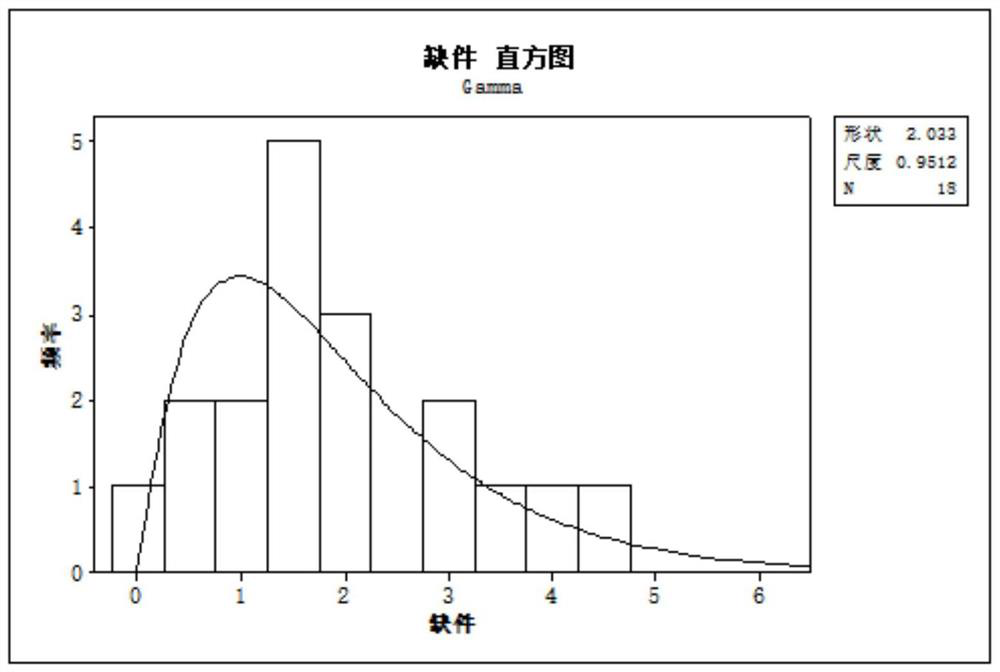

[0046] The main solution of the embodiment of the present application is to obtain historical production data of a target production line within a preset period, wherein the historical production data includes multiple downtime periods of the target production line every day, and each downtime period corresponds to At least one disturbance factor; according to the disturbance factor corresponding to each downtime period, obtain the disturbance period generated by each disturbance factor in each production stage; wherein, the target production line includes multiple production stages; Statistical distribution fitting is performed on the disturbance period generated by each disturbance factor, and the disturbance period distribution of each disturbance factor in each production stage is obtained; according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com