Extrusion device for coating cloth processing

A technology of coated cloth and extrusion box, which is applied to the device for coating liquid on the surface, coating, etc., can solve the problems of unfeeding speed and feeding speed, synchronization, and unbalanced heating of materials, etc., to achieve Reduce the time of heating and melting, improve work efficiency, and test the effect of a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

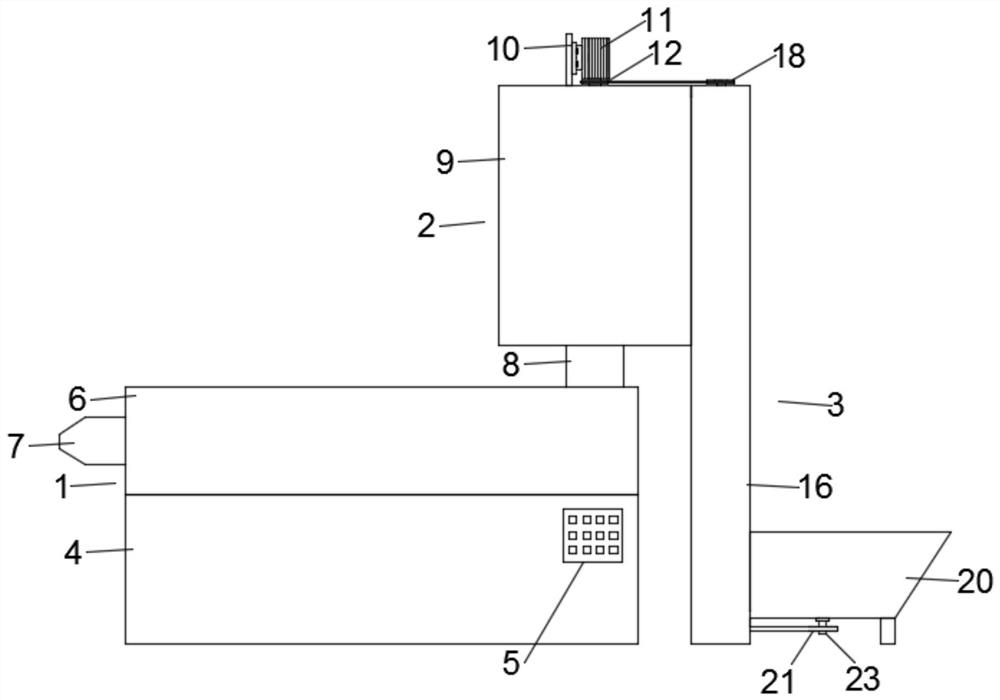

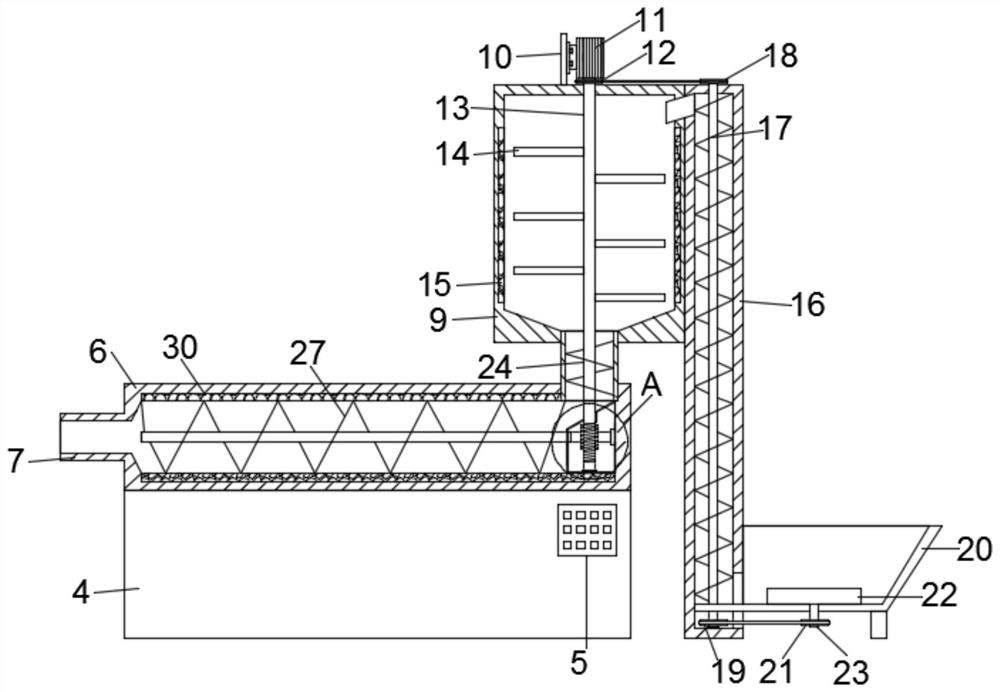

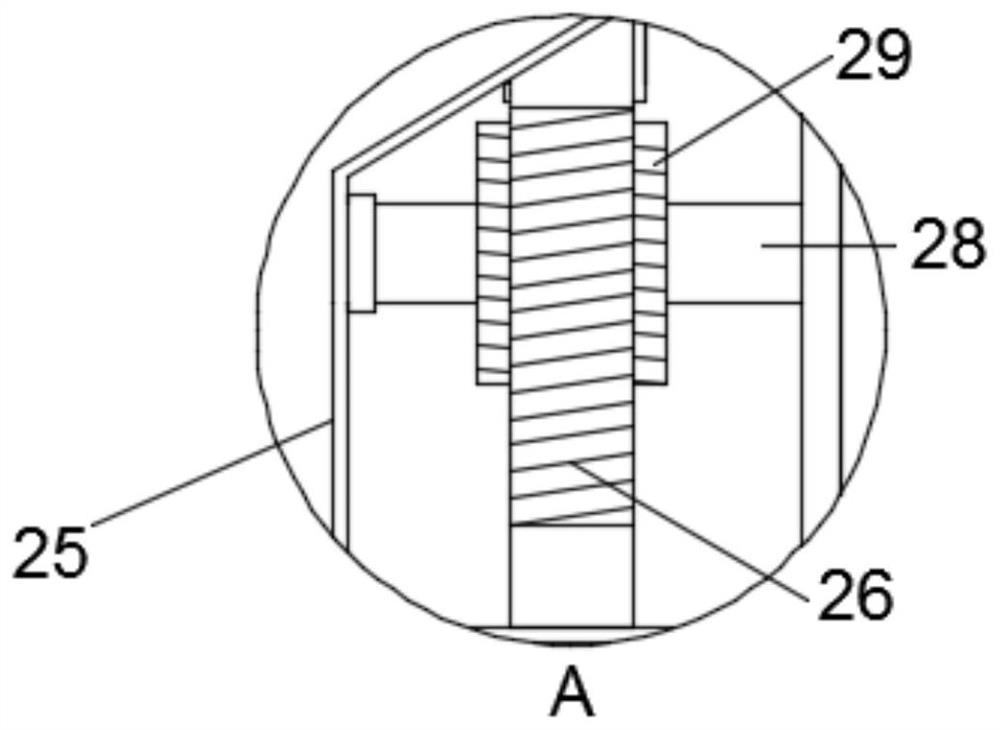

[0025] An extrusion device for coating cloth processing, comprising an extrusion mechanism 1, a preheating mechanism 2 and a conveying mechanism 3, a preheating mechanism 2 is provided above the extrusion mechanism 1, and a side of the preheating mechanism 2 is provided Conveying mechanism 3 is arranged, and described extruding mechanism 1 comprises support base 4, extruding box 6, extruding nozzle 7, sealing box 25, worm rod 26, screw extruding rod 27, output shaft 28, turbine 29 and melting heating plate 30, the top of the support seat 4 is fixedly connected with an extrusion box 6, and the inside of the extrusion box 6 is connected with a spiral extrusion rod 27, and the outer side of the spiral extrusion rod 27 is connected with the inner wall of the extrusion box 6 Sliding connection, one end of the extrusion box 6 is fixedly connected with an extrusion nozzle 7, the inside of the extrusion box 6 and one end away from the extrusion nozzle 7 is fixedly connected with a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com