Dust removal device for electrical automation equipment

A technology of electrical automation and dust removal device, which is applied in the direction of dust removal, transportation and packaging, cleaning methods and utensils, etc. It can solve problems such as poor use effect, affecting cleaning effect, and precision electrical components cannot be cleaned separately, so as to avoid secondary First attachment, guaranteed cleaning effect, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

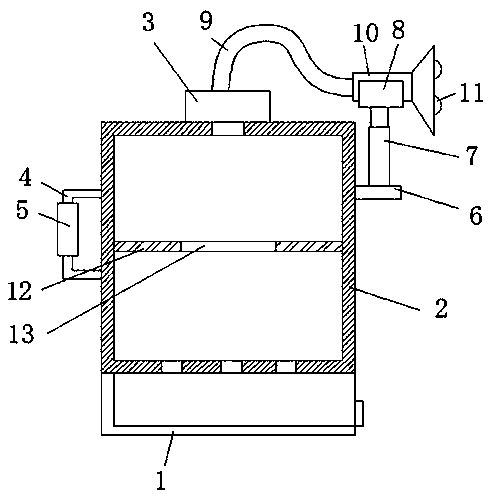

[0021] refer to figure 1 , a dust removal device for electrical automation equipment, comprising a base 1, the top of the base 1 is fixedly connected to a dust collection box 2, the top of the dust collection box 2 is fixedly connected to a dust suction fan 3, and one side of the dust collection box 2 is symmetrically fixedly connected to a handle frame 4. The handle frame 4 is covered with a non-slip sleeve 5, the other side of the dust collection box 2 is fixedly connected with a connecting plate 6, the top of the connecting plate 6 is fixedly connected with an electric push rod 7, and the top of the electric push rod 7 is fixedly connected with a clamp 8 , the top of the dust suction fan 3 is fixedly connected with a conveying leather tube 9, and one end of the conveying leather tube 9 is fixedly connected with a dust collection cover 10 on the fixture 8, and the inside of the dust collection cover 10 is symmetrically rotated and connected with a dust removal roller 11, and ...

Embodiment 2

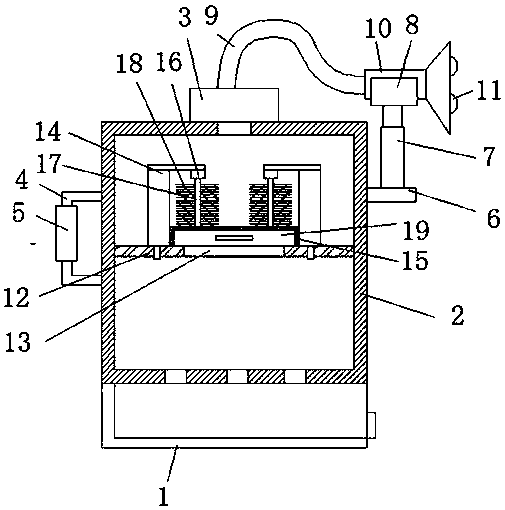

[0028] refer to figure 2 , a dust removal device for electrical automation equipment, comprising a base 1, the top of the base 1 is fixedly connected to a dust collection box 2, the top of the dust collection box 2 is fixedly connected to a dust suction fan 3, and one side of the dust collection box 2 is symmetrically fixedly connected to a handle frame 4. The handle frame 4 is covered with a non-slip sleeve 5, the other side of the dust collection box 2 is fixedly connected with a connecting plate 6, the top of the connecting plate 6 is fixedly connected with an electric push rod 7, and the top of the electric push rod 7 is fixedly connected with a clamp 8 , the top of the dust suction fan 3 is fixedly connected with a conveying leather tube 9, and one end of the conveying leather tube 9 is fixedly connected with a dust collection cover 10 on the fixture 8, and the inside of the dust collection cover 10 is symmetrically rotated and connected with a dust removal roller 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com