A device for removing iron scraps for grinding and processing of swing type cast iron materials

A swing type, power device technology, applied in the field of machinery, can solve the problems of secondary adhesion, getting on parts, generating waste and other problems, and achieves the effects of simple process, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

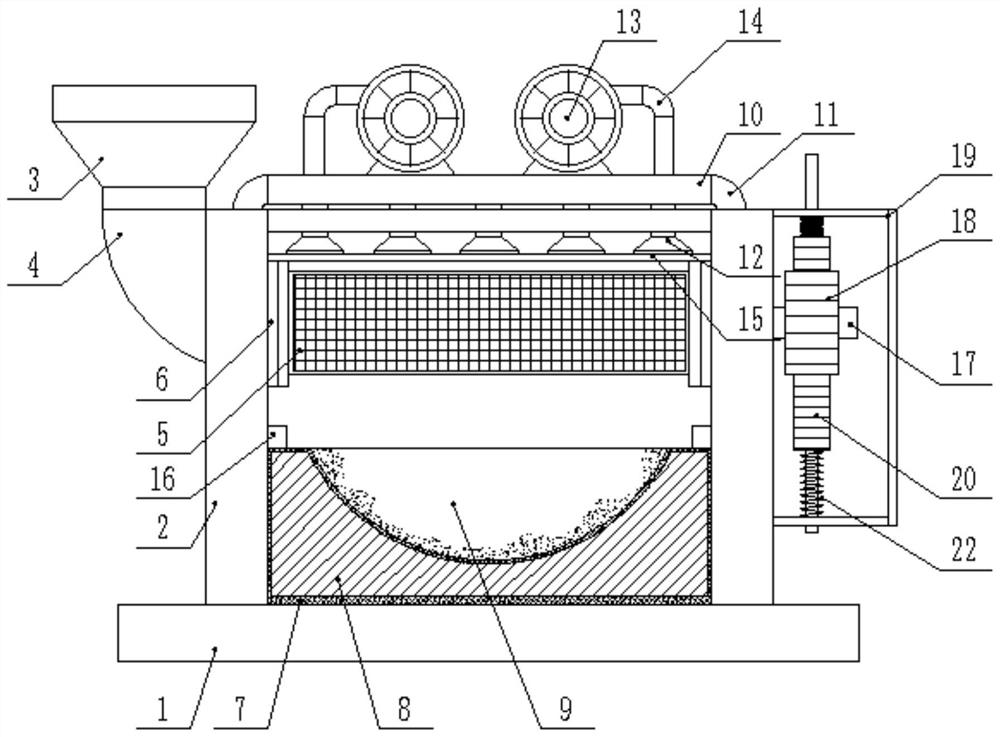

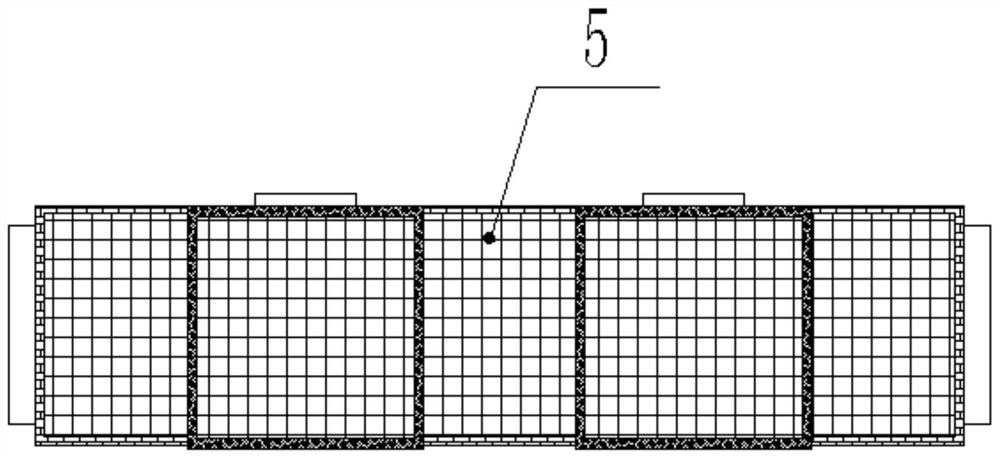

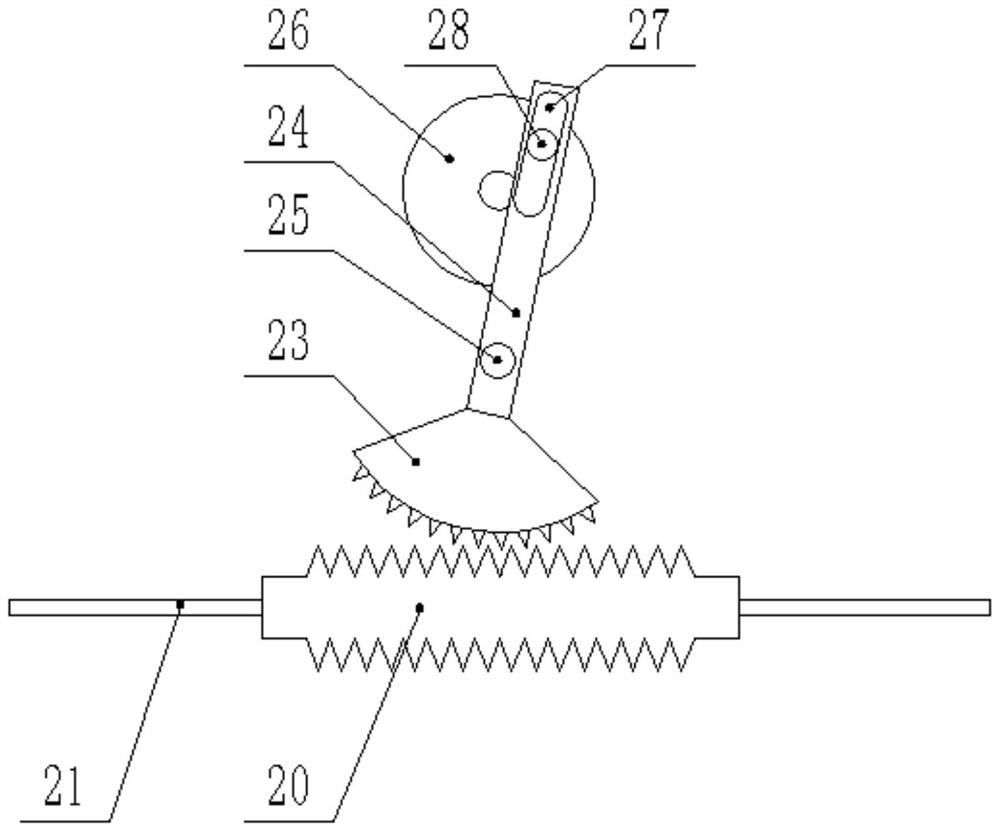

[0026] see Figure 1-3 A device for removing iron chips for grinding and processing of swinging cast iron materials, comprising a device body, a base 1 is arranged on the device body, a processing chamber 2 is arranged above the base 1, and the processing chamber 2 and the base 1 are fixedly connected by welding , the device body is provided with a feed hopper 3, the feed hopper 3 and the inside of the processing chamber 2 communicate with each other through the action of the feed pipe 4, and the feed pipe 4 and the outer wall of the processing chamber 2 are fixedly connected by the action of a fixing screw , the inside of the processing chamber 2 is provided with a rolling screen 5, the two ends of the rolling screen 5 and the inner wall of the processing chamber 2 are rotationally connected by the action of the bearing seat 6, the rolling screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com