Soil remediation system for environment-friendly landscaping maintenance

A landscaping and soil remediation technology, applied in the field of soil remediation systems, can solve problems such as affecting soil remediation and inability to spray, and achieve the effects of avoiding splashing, improving the remediation effect, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

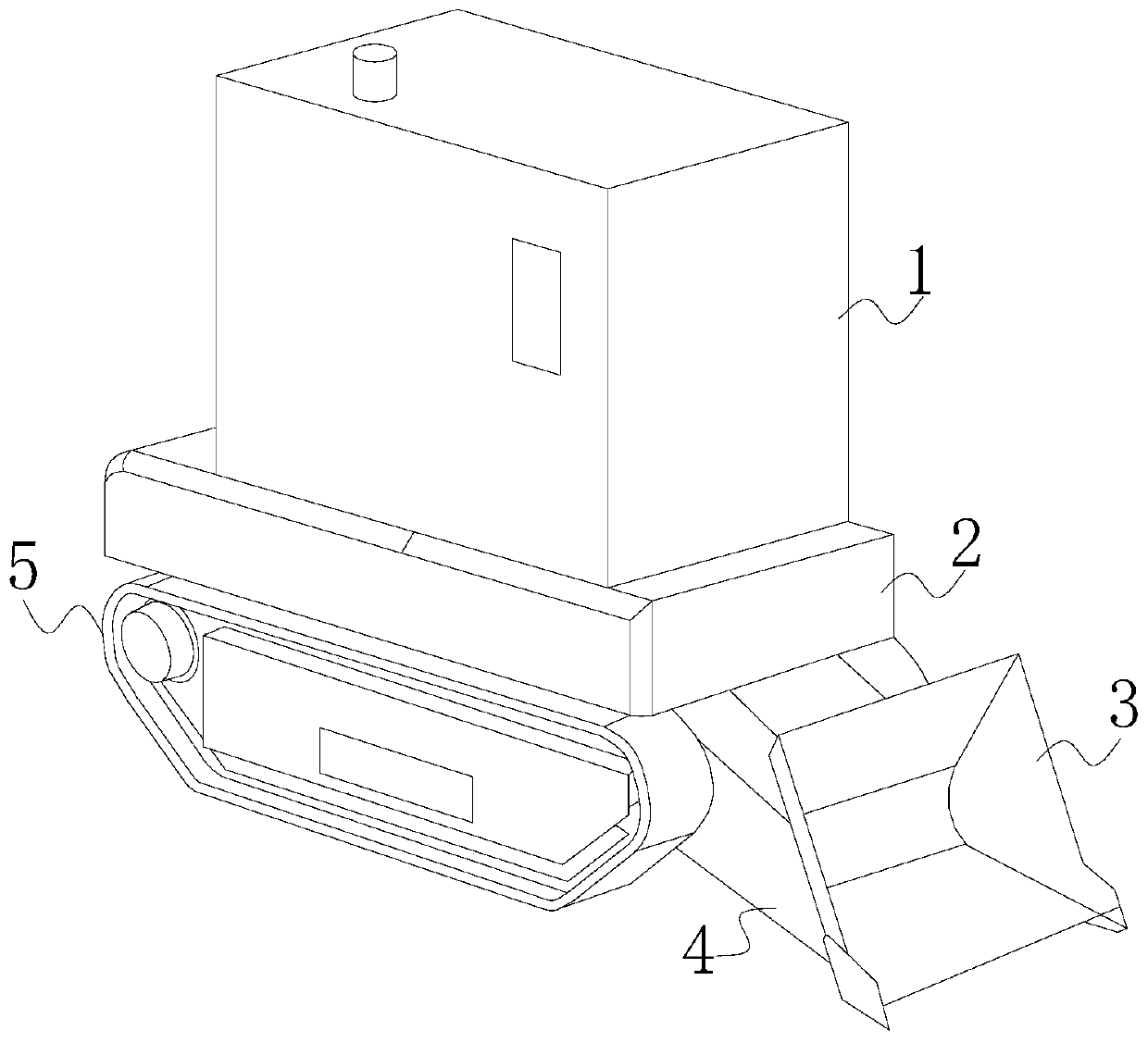

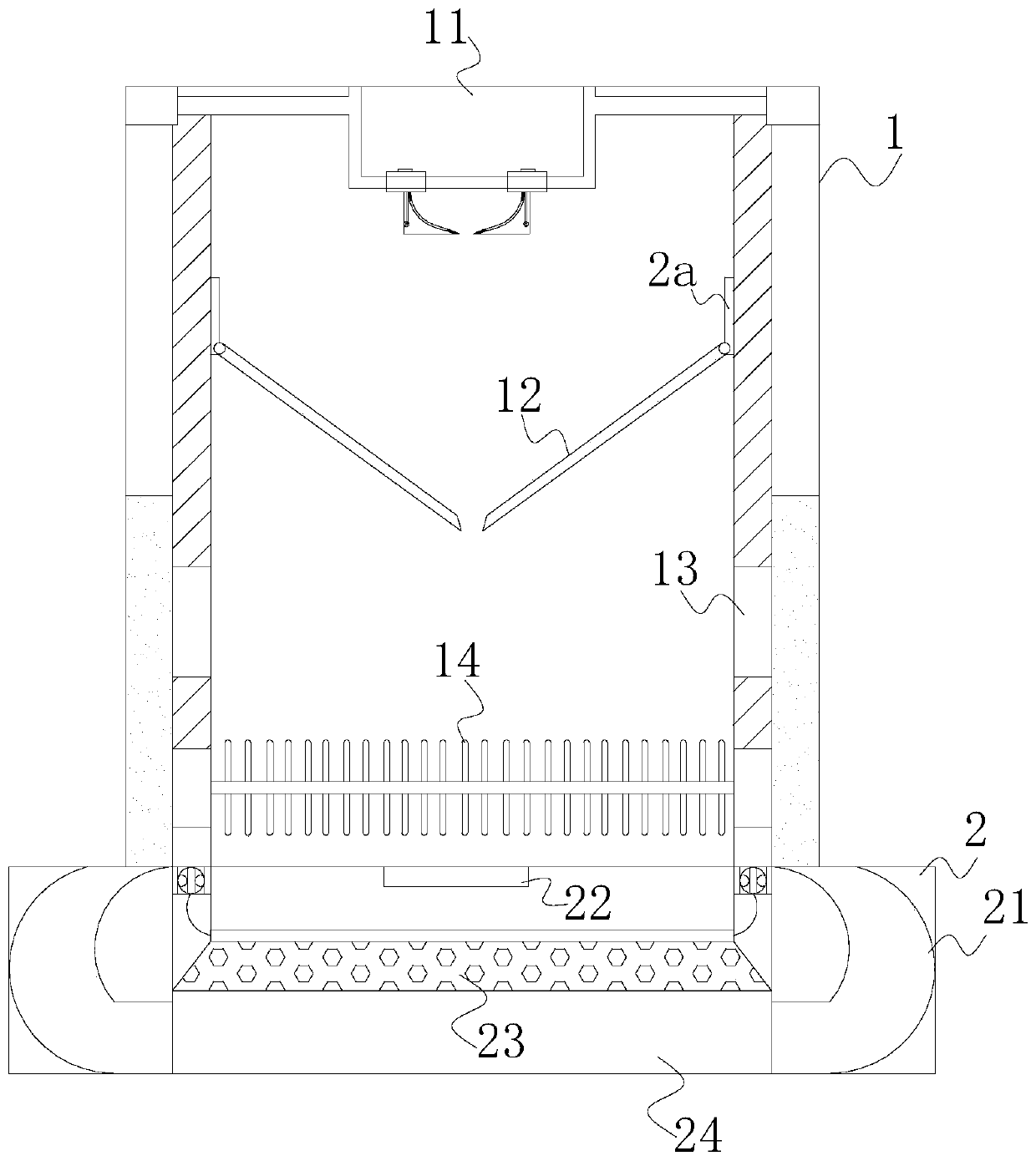

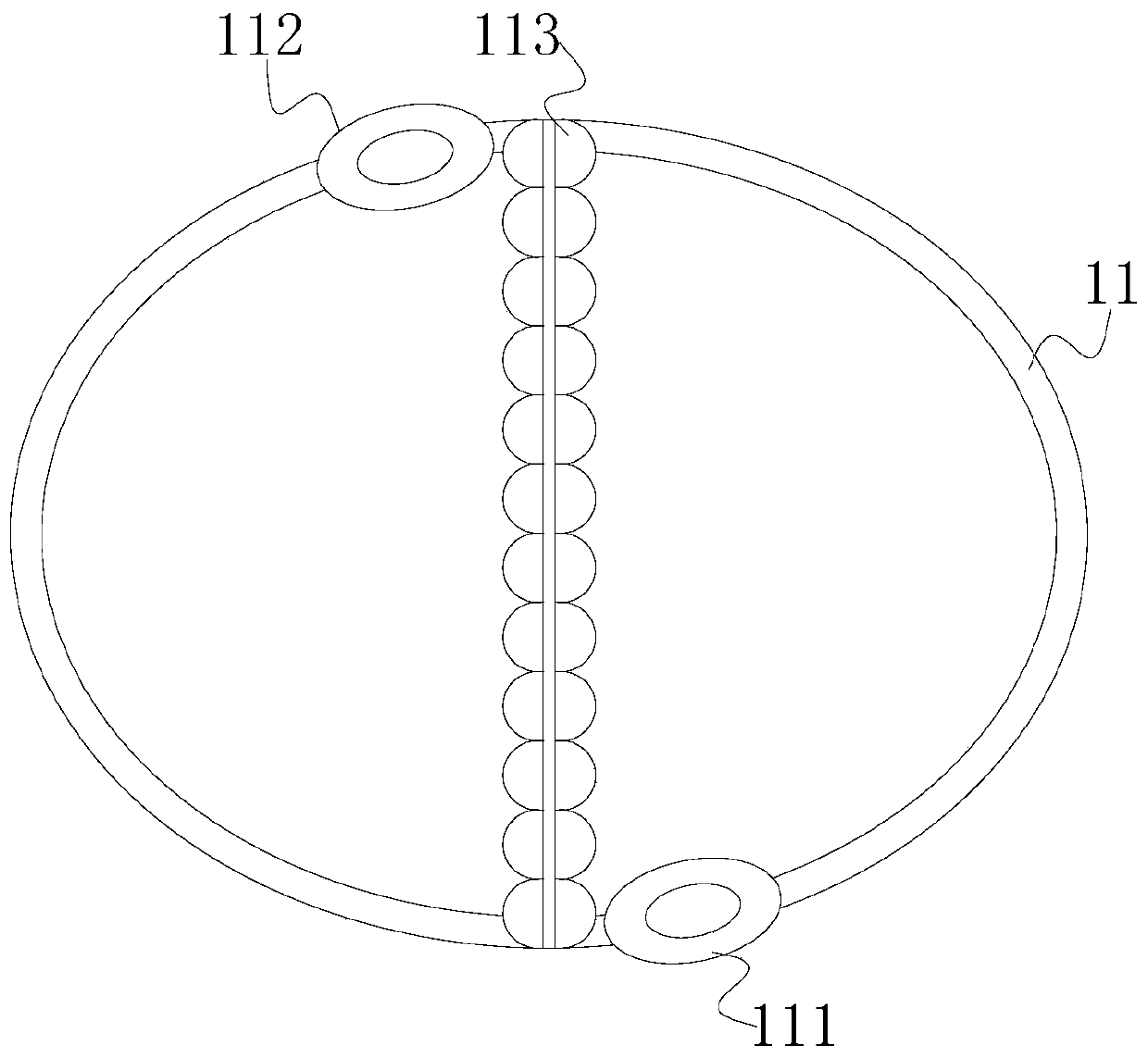

[0032] like Figure 1-Figure 3 As shown, the present invention provides a kind of soil remediation system that is used for environmental protection landscaping maintenance, and its structure comprises treatment box 1, screening box 2, soil inlet chamber 3, connecting pipe shaft 4, walking track 5, described treatment box 1 The bottom of the screen is fixed with a screening box 2, and the screening box 2 is connected with the soil inlet chamber 3 through the connecting pipe shaft 4, and the walking track 5 is mechanically connected to both sides of the bottom of the screening box 2, and the processing box 1 There are walking ring 11, sloping plate 12, outlet 13 and stirring shaft 14 inside. The walking ring 11 is installed on the upper end of the processing box 1. There are two sloping plates 12, which are fixed on the processing box by mechanical connection. On both sides of the inner wall of 1, the stirring shaft 14 is horizontally connected below the swash plate 12, and the ...

Embodiment 2

[0034] like Figure 4-Figure 6 As shown, on the basis of Embodiment 1, the first shower 111 is composed of a driver 11a, a traveling wheel 11b, and a sprinkler head 11c. The spray head 11c is fixed together, the sprinkler head 11c is a right triangle structure, the atomization port c1 is arranged in the slope, the support shaft c3 and the connecting rod c2 are arranged on the sprinkler head 11c, and the connecting rod c2 and the support The shaft c3 and the sprinkler head 11c form an umbrella-shaped structure and are fixedly connected to the traveling wheel 11b. The slant plate 12 is provided with a sliding interface 2a, an interface seat 2b, and a plate surface 2c. The interface seat 2b and the plate surface 2c are integrated. The two form a wave shape, the sliding interface 2a is fixed on the interface seat 2b, the atomizing port c1 and the inclined plate 12a adopt a staggered fit, the repair liquid sprayed in the atomizing port c1 does not touch, and the inclined plate 12a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com