Powder recycling device and method for metal three-dimensional printing device

A 3D printing and recycling device technology, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve problems such as increased oxygen content, and achieve the effect of simplifying operation, ensuring sealing, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A powder recovery device for metal 3D printing equipment, including a recovery bottle and a ventilation tube, the recovery bottle is provided with a powder recovery port, a valve is installed on the powder recovery port, and the ventilation tube extends through the valve to the recovery inside the bottle.

[0043] In this embodiment, the valve is a butterfly valve. It is convenient to clean and recover the metal powder in the bottle after opening.

[0044] During the operation of the 3D printing equipment, when it is necessary to clean the powder in the recovery bottle, first close the valve on the recovery pipeline of the 3D printing equipment, remove the recovery bottle, open the butterfly valve to clean the powder in the recovery bottle; then extend the ventilation pipe through the butterfly valve to the recovery Inside the bottle, the inert gas is passed into the recovery bottle through the ventilation tube, and then the air in the recovery bottle is discharged, so...

Embodiment 2

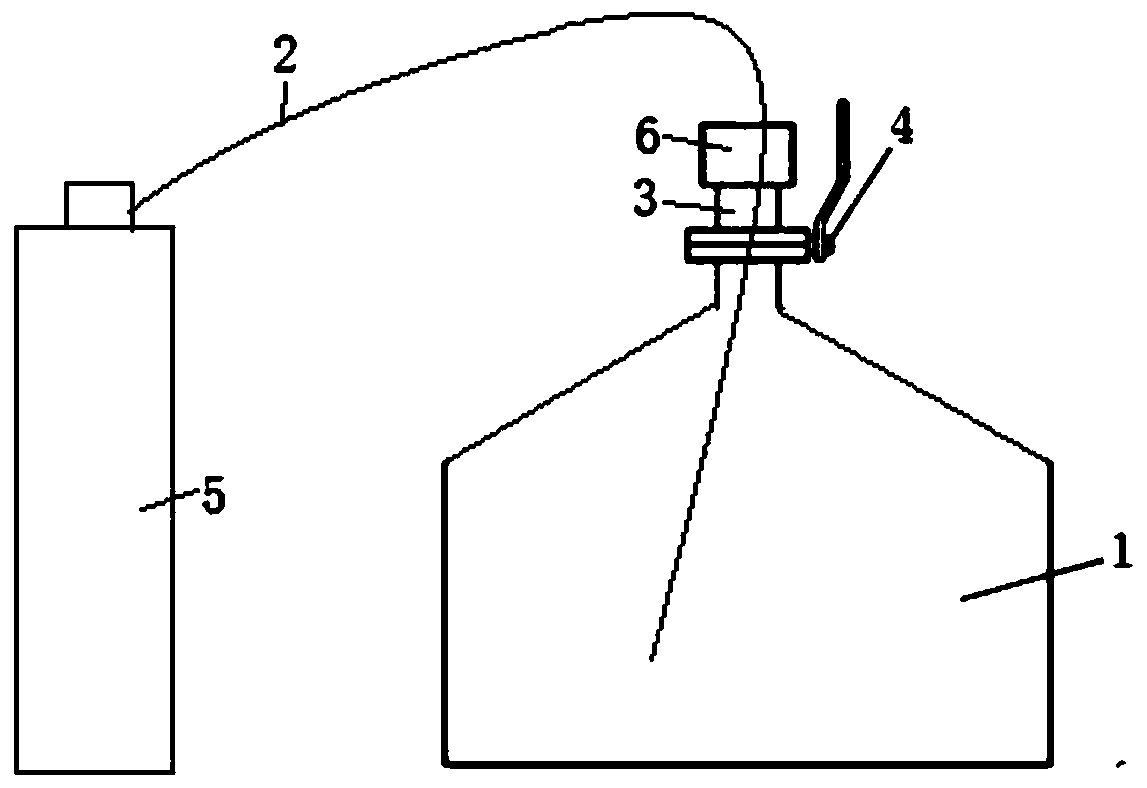

[0046] Such as figure 1 As shown, a powder recovery device for metal 3D printing equipment includes a recovery bottle and a ventilation tube, the recovery bottle is provided with a powder recovery port, and a valve is installed on the powder recovery port, and the ventilation tube passes through the valve Extends to the inside of the recovery bottle.

[0047] In this embodiment, the valve is a butterfly valve.

[0048] The ventilation tube is connected with a non-oxidizing gas generating device, and the non-oxidizing gas generating device is an argon cylinder.

[0049] The powder recovery port is also equipped with a detection system, the detection system is XP-3180 handheld oxygen content detector, the detection system includes an oxygen sensor probe and a digital display device, used to detect the oxygen content in the recovery bottle, to ensure the recovery The oxygen content in the bottle meets the equipment usage index. First, close the valve and the butterfly valve co...

Embodiment 3

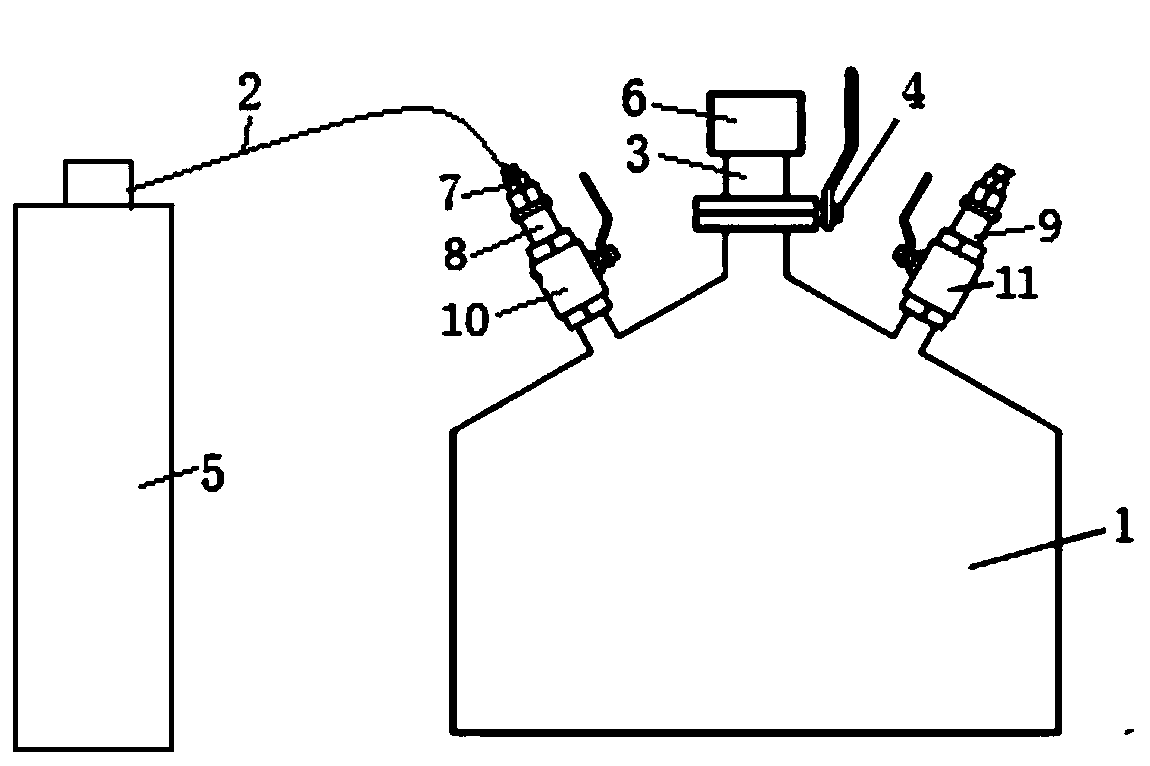

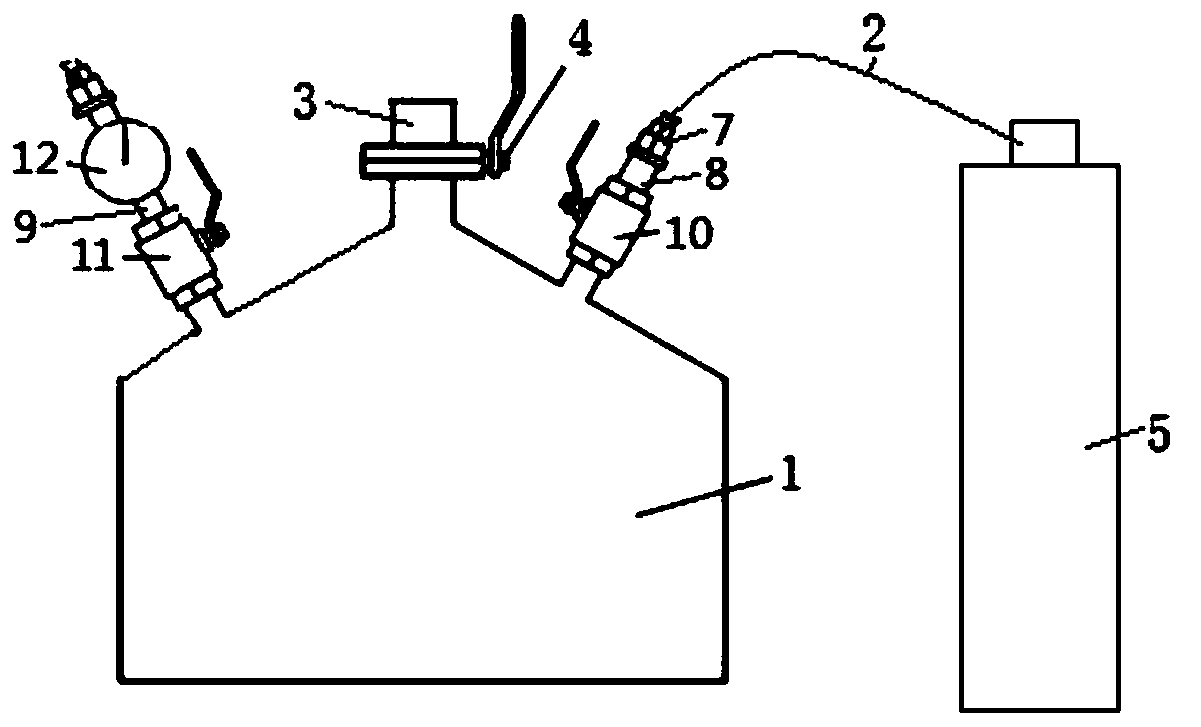

[0052] Such as figure 2 As shown, a powder recovery device for metal 3D printing equipment includes a recovery bottle and a ventilation tube. The recovery bottle is provided with a powder recovery port, and a butterfly valve is installed on the powder recovery port.

[0053]The ventilation tube is connected with a non-oxidizing gas generating device, and the non-oxidizing gas generating device is an argon gas bottle, and the argon gas in the argon gas bottle has a purity of 99.999% high-purity argon.

[0054] The powder recovery device for metal 3D printing equipment also includes a quick plug for the trachea, and the top and bottom of the recovery bottle are provided with a quick plug interface for the trachea and an air outlet interface. In this embodiment, the quick plug interface for the trachea and the air outlet The interfaces are all located on the top of the recovery bottle. The trachea quick plug is detachably connected to the trachea quick plug interface and the air...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap