3D printing machine

A 3D printer and chassis technology, applied in the field of 3D printing, can solve the problems of replacing parts, short service life, manual focusing, etc., to increase the service life, improve the service life, and ensure the effect of printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

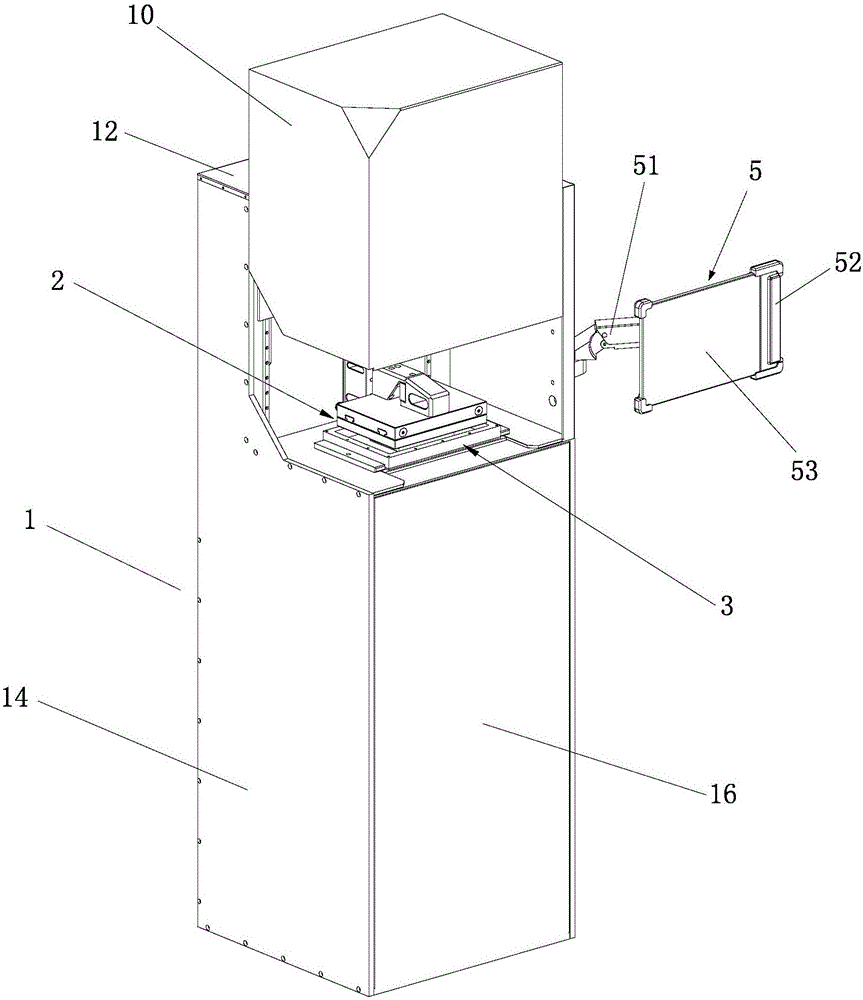

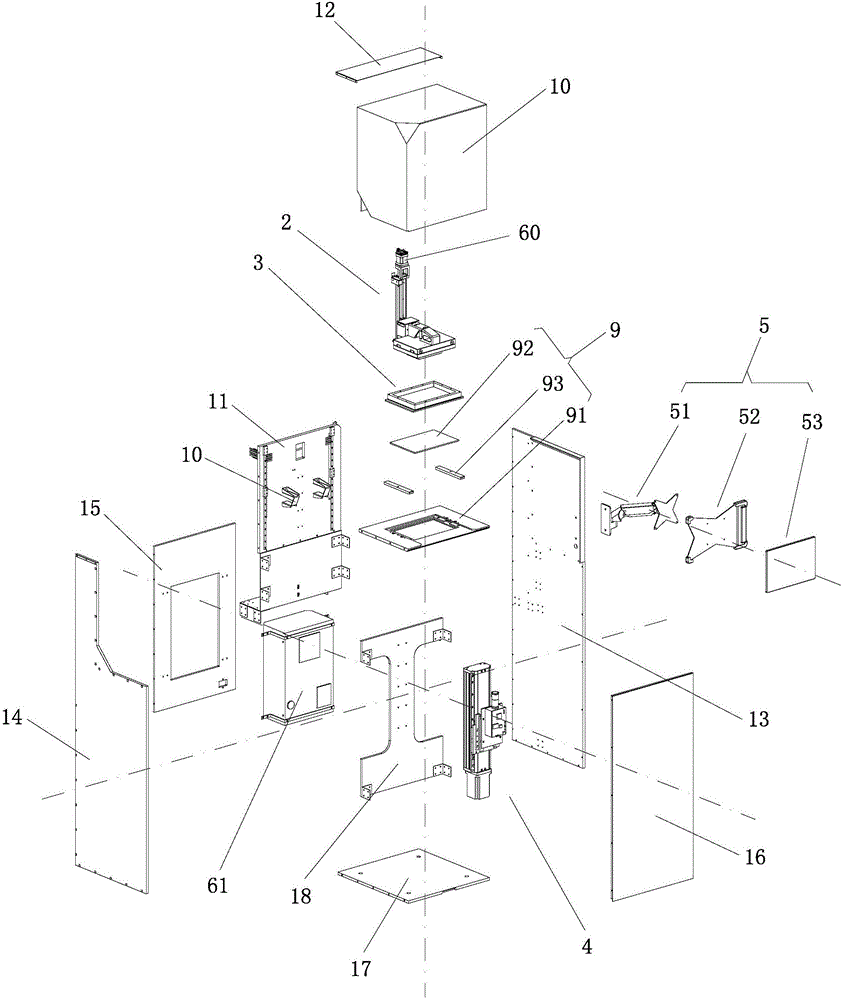

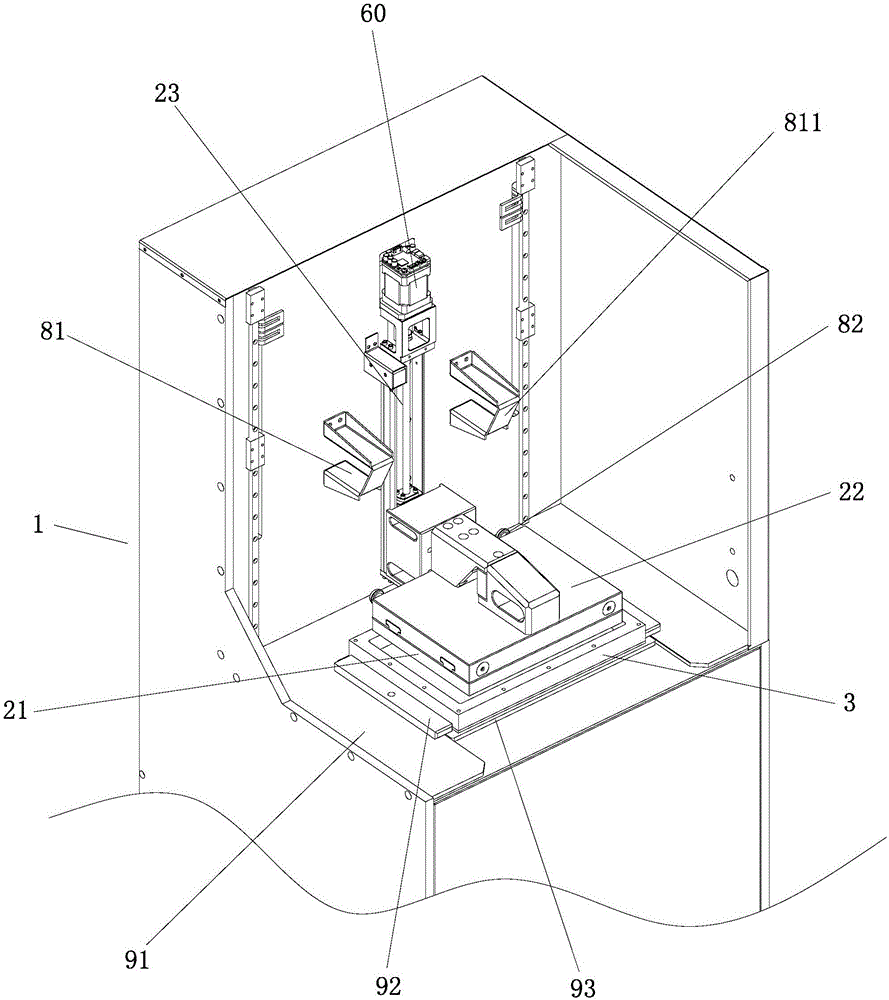

[0036] Such as Figure 1 to Figure 12 As shown, the 3D printer of the present invention is characterized in that it includes an organic case 1, a forming platform assembly 2 installed on the upper part of the case 1, a material tray 3, a dimmable machine assembly 4 installed on the lower part of the case 1, and an assembly installed outside the case 1. The control platform 5, the forming platform assembly 2 and the dimmable machine assembly 4 are all provided with a motor 60, the forming platform assembly 2 is provided with a force feedback system, and the motor 60 and the force feedback system are all connected to the control platform 5 The control system is electrically connected, so the control system and the force feedback system can cooperate with each other to realize effective control of the lifting speed of the forming platform 21.

[0037] Such as figure 2 As shown, the cabinet 1 of this embodiment includes an upper part and a lower part, and a transparent interlaye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com