Broaching machine used for machining key grooves

A keyway and bed body technology, applied in the field of broaching machines for keyway processing, can solve problems affecting machining accuracy, workpiece position offset, production loss, etc., and achieve the effect of increasing processing efficiency and preventing smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

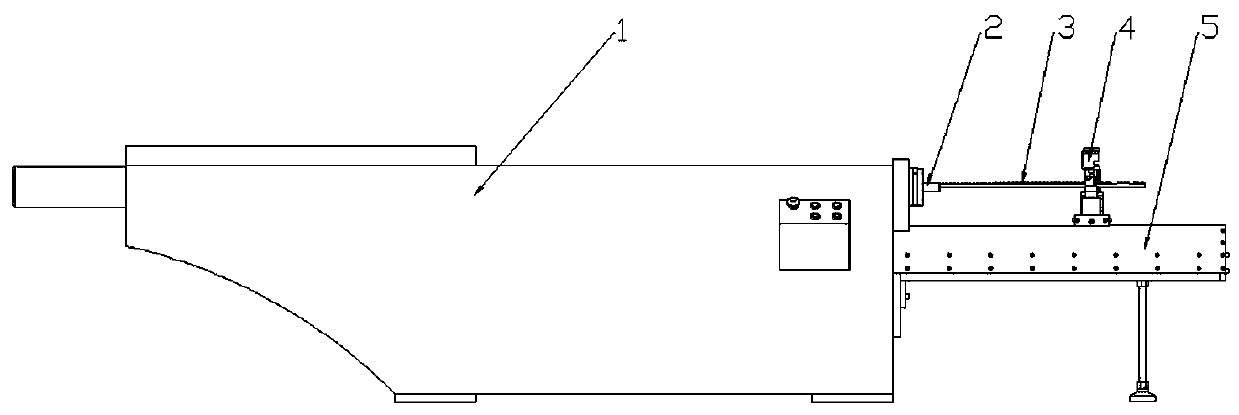

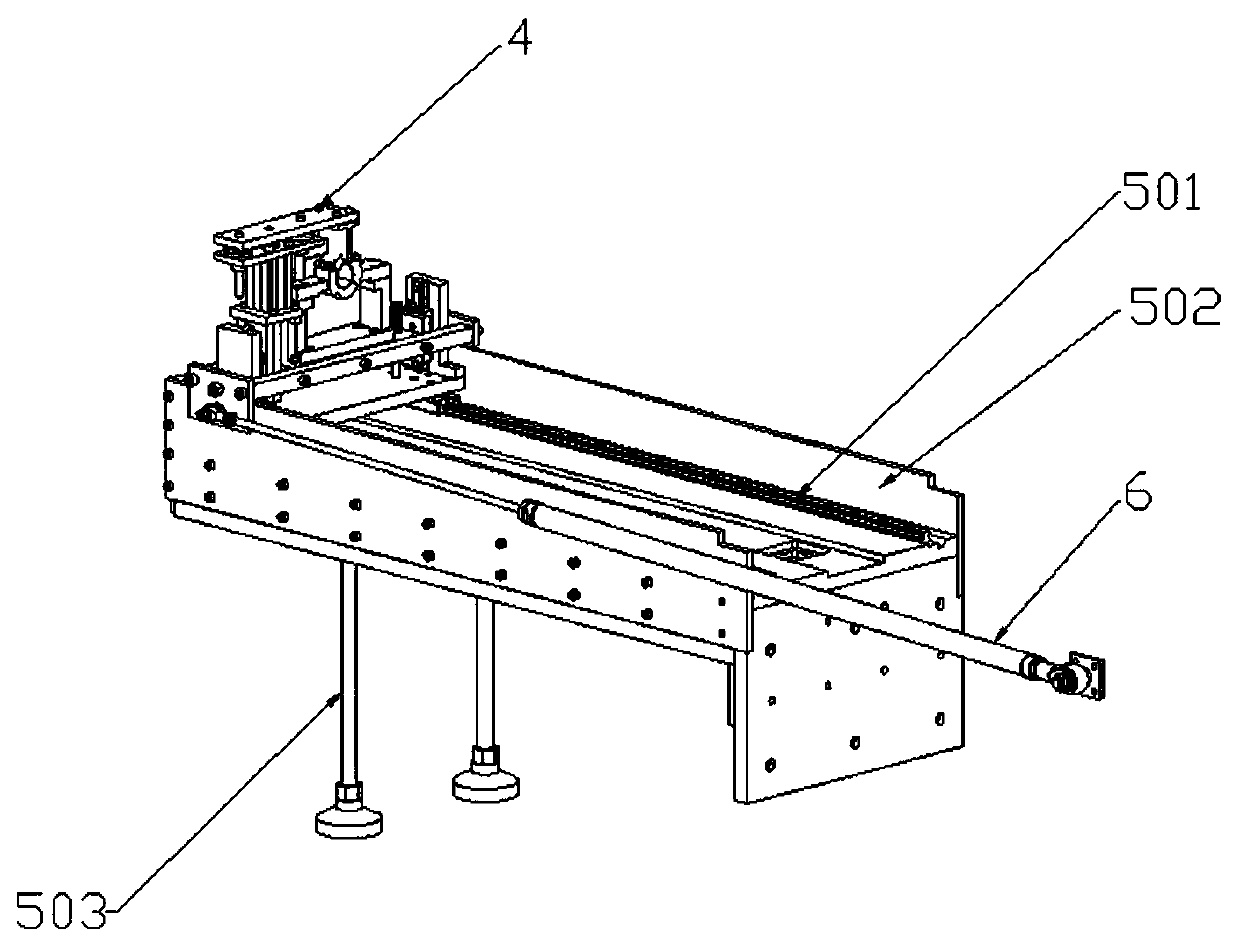

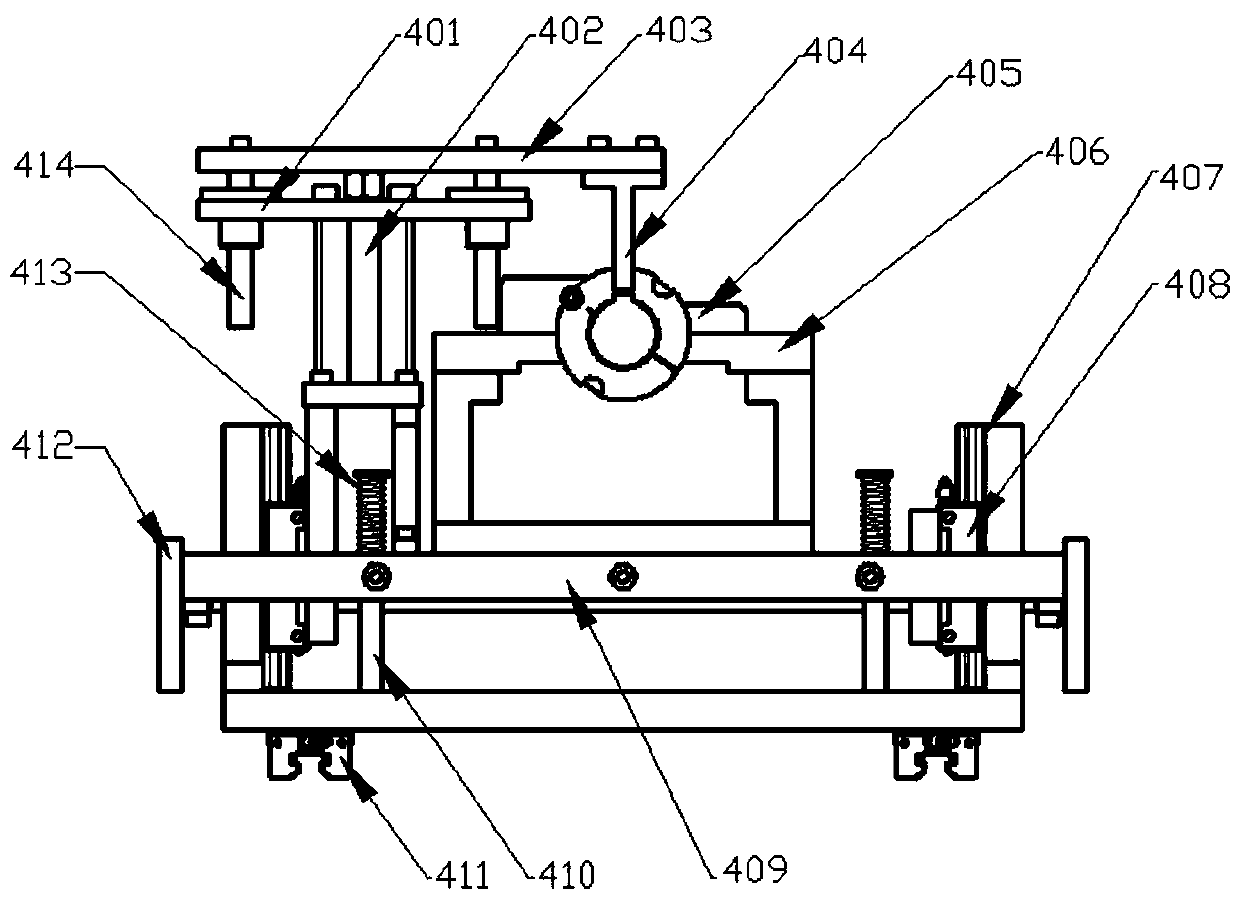

[0020] Such as figure 1 As shown, a broaching machine for processing keyways includes a bed body 1, a workbench 5 and a clamp 4, and the bed body 1 is provided with a tool seat 2 for controlling the movement of the broach 3, and the tool seat 2 is provided with a broach 3, the workbench 5 is connected to the bed body 1 and is located below the broach 3, the clamp 4 includes a bottom plate and a middle plate, and vertical guide rails 407 are arranged on the left and right sides of the bottom plate, The left and right sides of the middle plate are provided with second sliders 408, and the sliders cooperate with the vertical guide rails 407 to make the distance between the middle plate and the bottom plate adjustable. Bar 409, both ends of the horizontal bar 409 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com