Rubber plug punching device

A technology of punching device and rubber plug, which is applied in metal processing and other directions, can solve the problems of high cost, labor, and difficulty in verticality, and achieves the effect of simple structure and good punching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

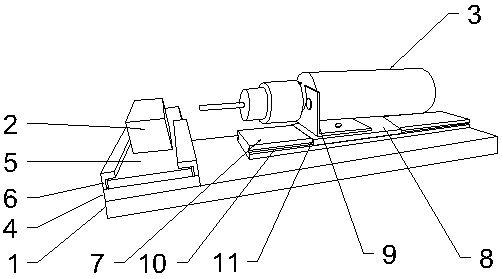

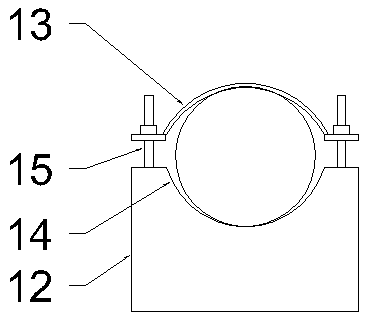

[0012] The present invention will be further described below in conjunction with all the accompanying drawings. The rubber plug punching device described in this embodiment includes a base 1 and an electric drill 3. A longitudinal sliding assembly is installed on the top of one end of the base 1, and a rubber plug fixing card is installed on the longitudinal sliding assembly. 2. A horizontal sliding assembly is installed on the top of the other end of the base 1, and the electric drill 3 is installed on the horizontal sliding assembly; the longitudinal sliding assembly includes a longitudinal sliding seat 4 and a longitudinal sliding block 5, wherein the longitudinal sliding seat 4 is rectangular, and the vertical sliding assembly is The bottom of the sliding seat 4 is fixed on the top of one side of the base 1, and the top of the longitudinal sliding seat 4 extends upwards on both sides in the length direction and then bends to form a longitudinal chute 6. The longitudinal slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com