Conveying frame for cosmetic box filling

A technology of cosmetic boxes and conveyor racks, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems that cosmetic boxes are prone to offset and affect the filling of cosmetic boxes, and achieve simple structure, user-friendly use, and mobile convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

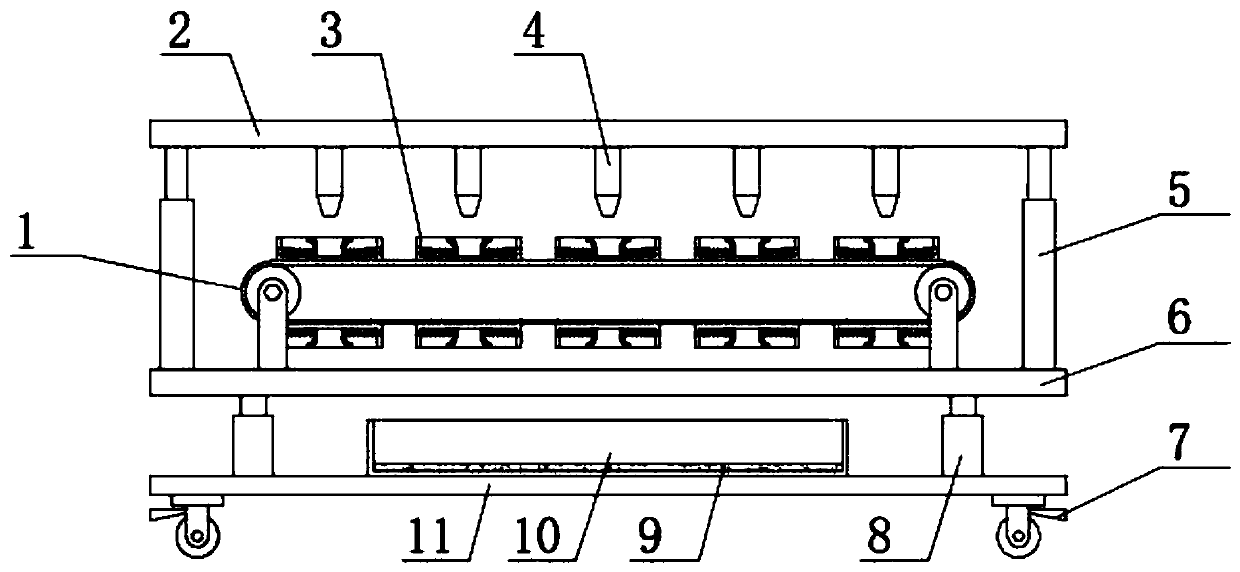

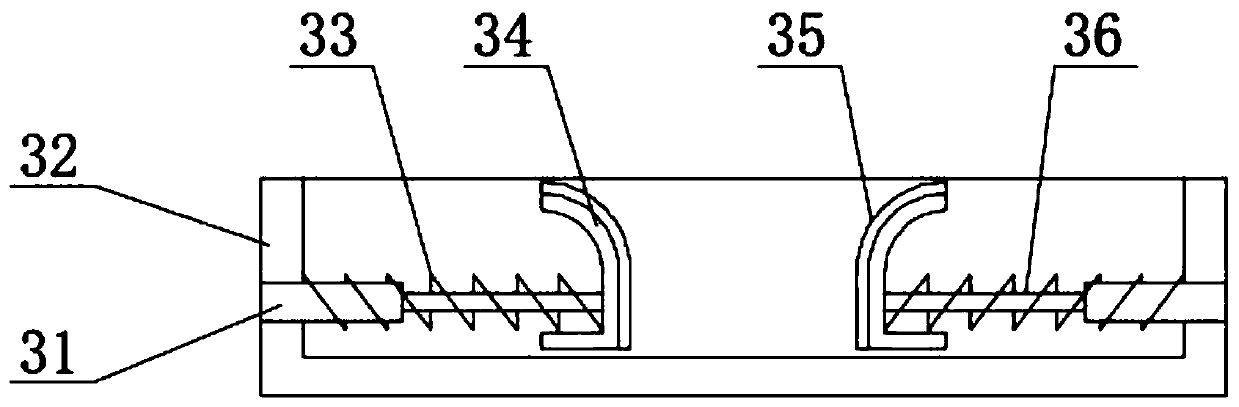

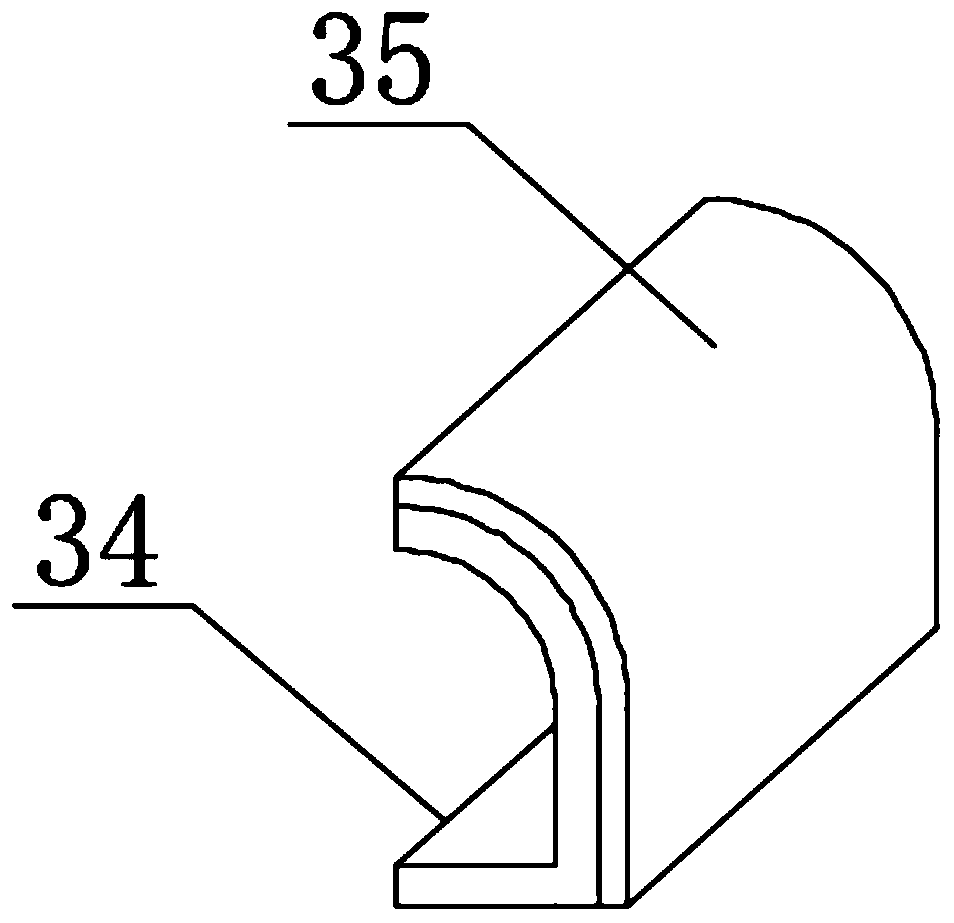

[0021] see Figure 1-Figure 4 , the present invention provides a technical solution: a conveyor rack for cosmetic box filling, including a second support plate 6, a first support plate 2 is arranged above the second support plate 6, and the upper surface of the second support plate 6 is two The end is welded with the first electric telescopic rod 5 corresponding to the first support plate 2, the lower surface of the first support plate 2 is provided with a feeding nozzle 4, and the conveyor belt 1 is provided under the feeding nozzle 4, and the surface of the conveyor belt 1 is provided with Fixed mechanism 3 is arranged, and fixed mechanism 3 comprises limit base 32, and the inside of limit base 32 is provided with fixture 34, and the bottom end of fixture 34 is provided with limit bar 36, and the bottom end of limit base 32 is provided with limiter. The limit tube 31 corresponding to the rod 36, the limit spring 33 is arranged on one side of the fixing member 34, and the ant...

Embodiment 2

[0025] see Figure 1-Figure 4 , on the basis of embodiment 1, the cosmetic box filling conveyor frame of embodiment 2 includes a second support plate 6, the top of the second support plate 6 is provided with a first support plate 2, and the upper surface of the second support plate 6 The two ends are welded with the first electric telescopic rod 5 corresponding to the first support plate 2, the lower surface of the first support plate 2 is provided with a feeding nozzle 4, and the lower surface of the feeding nozzle 4 is provided with a conveyor belt 1, and the surface of the conveyor belt 1 Fixed mechanism 3 is provided, and fixed mechanism 3 comprises limit base 32, and the inside of limit base 32 is provided with fixture 34, and the bottom end of fixture 34 is provided with limit bar 36, and the bottom end of limit base 32 is provided with and limit. The position-limiting tube 31 corresponding to the position bar 36 is provided with a position-limiting spring 33 on one side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap