Epoxy resin for high-gloss self-curing powder coating and two-pot preparation method

An epoxy resin and powder coating technology, applied in powder coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of uneven dispersion, long premixing time, batch curing differences, etc., and meet the requirements of miscibility Low, high gloss, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Prepare the main raw materials in the following mole fractions:

[0053] Bisphenol A 5mol; 1,10-sebacic acid 7mol; epichlorohydrin 12mol; sodium hydroxide 15mol; monobutyl trimellitic acid 8mol; adipic acid 10mol; terephthalic acid 12mol; diethylene glycol 13mol; 8 mol of glyceryl isostearate; 6 mol of triglycidyl isocyanurate; the following method is carried out according to the above-mentioned amount of raw materials.

[0054] A double-pot preparation method for epoxy resin for high-gloss self-curing powder coatings, comprising the following steps:

[0055] (1) Dissolve sodium hydroxide in water to prepare a sodium hydroxide solution with a mass concentration of 40%, then add it to the first reaction kettle, and heat up to 50°C, then add bisphenol A, 1,10-decanedi Acid and the first catalyst, heat up to 60°C and keep it warm for 2 hours. When the pH reaches about 9.5, start adding epichlorohydrin dropwise. The dropwise addition is completed within 2 hours. Keep it at...

Embodiment 2

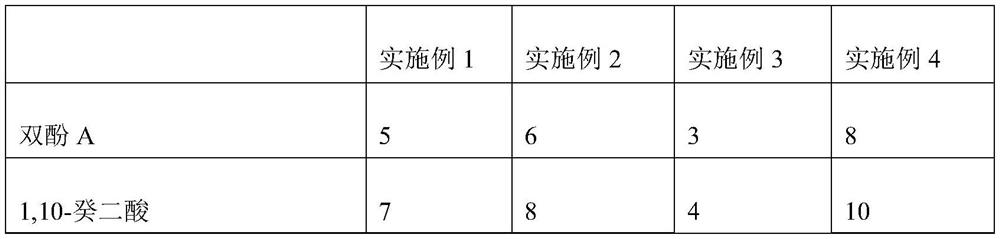

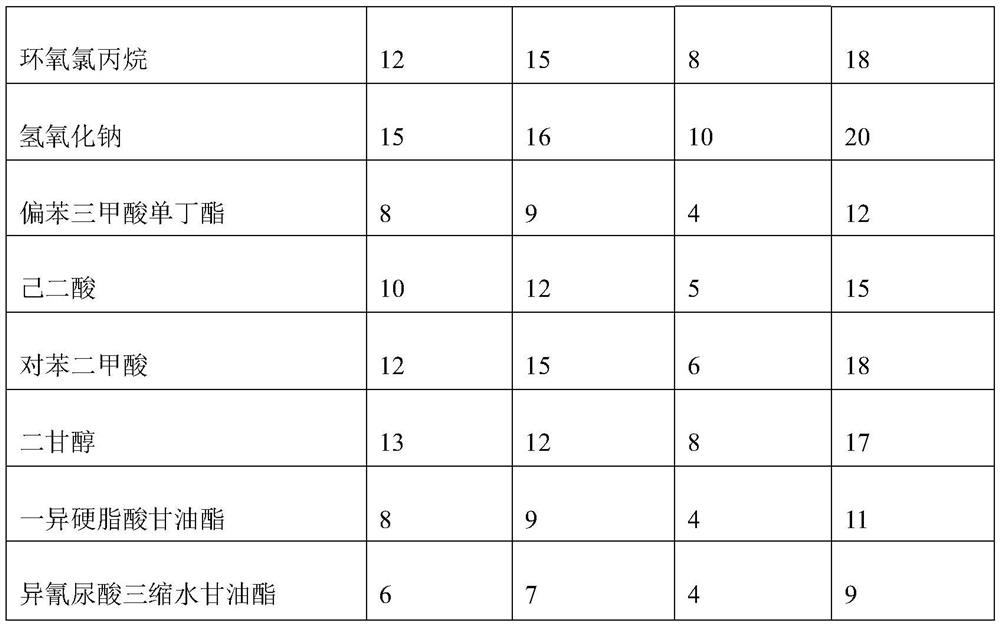

[0063] The consumption of each raw material among embodiment 2 and embodiment 4 is different from embodiment 1, specifically as follows:

[0064] The consumption (mol) of each raw material in table 1 embodiment 1~4

[0065]

[0066]

Embodiment 5

[0085] Embodiments 1 to 4 Grades Comparative Examples 1 to 5 adopt the following powder coating formula, and the formula is usually as follows in parts by weight:

[0086]

[0087] Preparation of powder coating: according to the formula of the above powder coating, all materials are mixed evenly, extruded rapidly (within 5min) with a single-screw extruder, pressed into tablets, crushed, and then the flakes are crushed and sieved to make a powder coating (160 -200 mesh). The powder coating is sprayed on the surface-treated tinplate substrate with an electrostatic spray gun, and cured at 180°C / 15min to obtain the coating.

[0088] Comparative Example 6 and Comparative Example 7 use finished powder coatings for performance comparison without additional preparation of powder coatings.

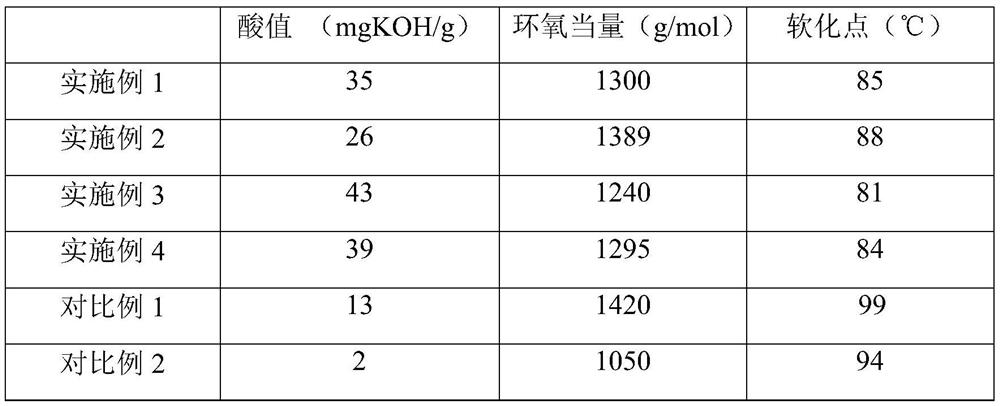

[0089] performance comparison

[0090] The test method of epoxy equivalent is based on GB / T 4612-2008 "Determination of epoxy equivalent of plastic epoxy compounds"

[0091] Coating index tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com