Liquid supply system for anodized foil forming electrolyte

A technology of foil formation and electrolyte, applied in anodic oxidation, electrolytic coating, electrolytic process, etc., can solve the problems of increasing defective products, affecting product quality, affecting production line output, etc., to prevent defective products or increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024] A set of high-level liquid supply system in this application is the above-mentioned liquid supply system, which uses independent tanks to configure the original liquid according to the standard ratio. The single tank is equipped with an independent circulation system. After the circulation is sufficient, the original liquid in the tank is configured and used through the pipeline. The magnetic pump is sent to the liquid supply tank. The liquid supply tank contains an independent circulation system and is transported to the high-level tank by a magnetic pump. The high-level tank is placed on a steel structure platform above 7M. The raw liquid is delivered to the chemical production line in a self-pressurized way. The high-level liquid supply system achieves consistent liquid supply pressure through self-circulation and constant liquid level, stabilizes the flow rate required by production, and stabilizes quality.

[0025] Specifically, the configuration tank is made of pol...

Embodiment 1

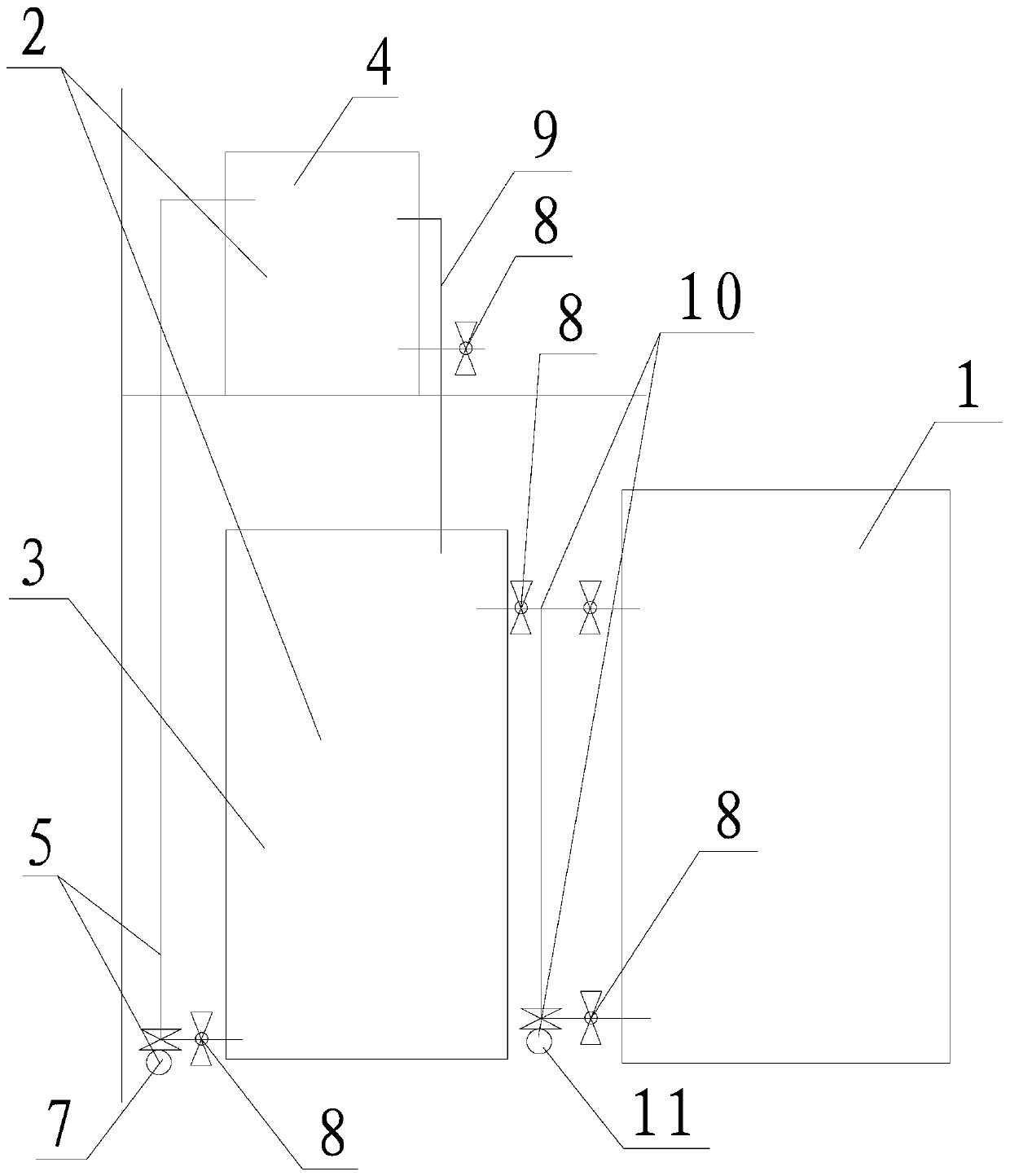

[0027] Such as figure 1 A high-level liquid supply system shown includes an independent configuration tank, a circulating liquid supply system installed in the configuration tank of the preparation tank, including pipelines, a magnetic pump, a liquid supply tank, and a liquid supply system installed in the configuration tank, including pipes Road, magnetic pump, high-level tank, self-pressurized liquid supply pipeline, switch valve control, the high-level tank needs to be elevated by 7 meters, and the steel structure is used to weld the elevated; the configuration tank has a volume of 15m 3 , after the stock solution configuration is completed, give priority to its own circulation system to fully circulate the stock solution, after passing the test, pass figure 1 In the magnetic pump, the magnetic pump adopts a lift of 15 meters and a flow rate of 6.3m 3 / h, the circulation pipeline adjusts the valve and transfers to the liquid supply tank. The circulation pipeline is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com