Shearing system for longwall mining

一种长壁、剪切机的技术,应用在剪切系统领域,能够解决错误、不正确布置等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

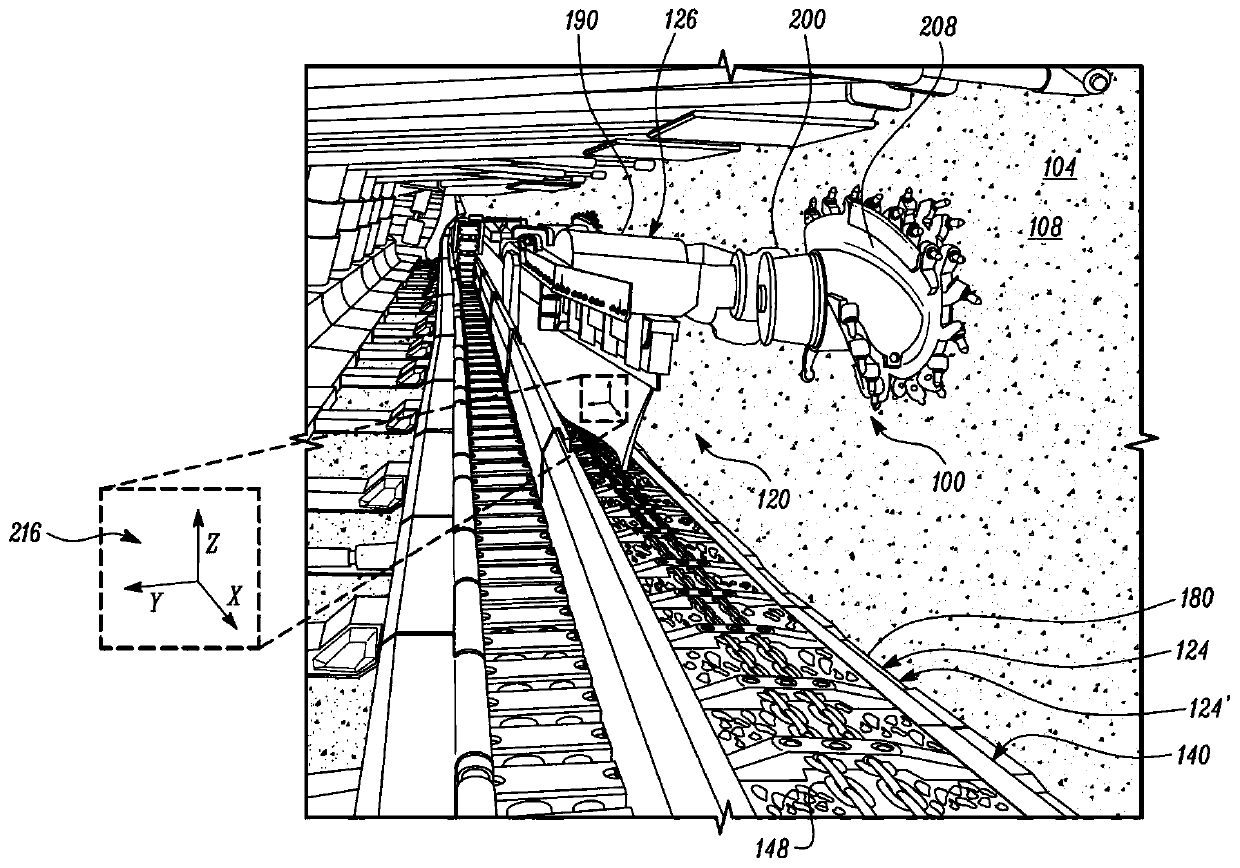

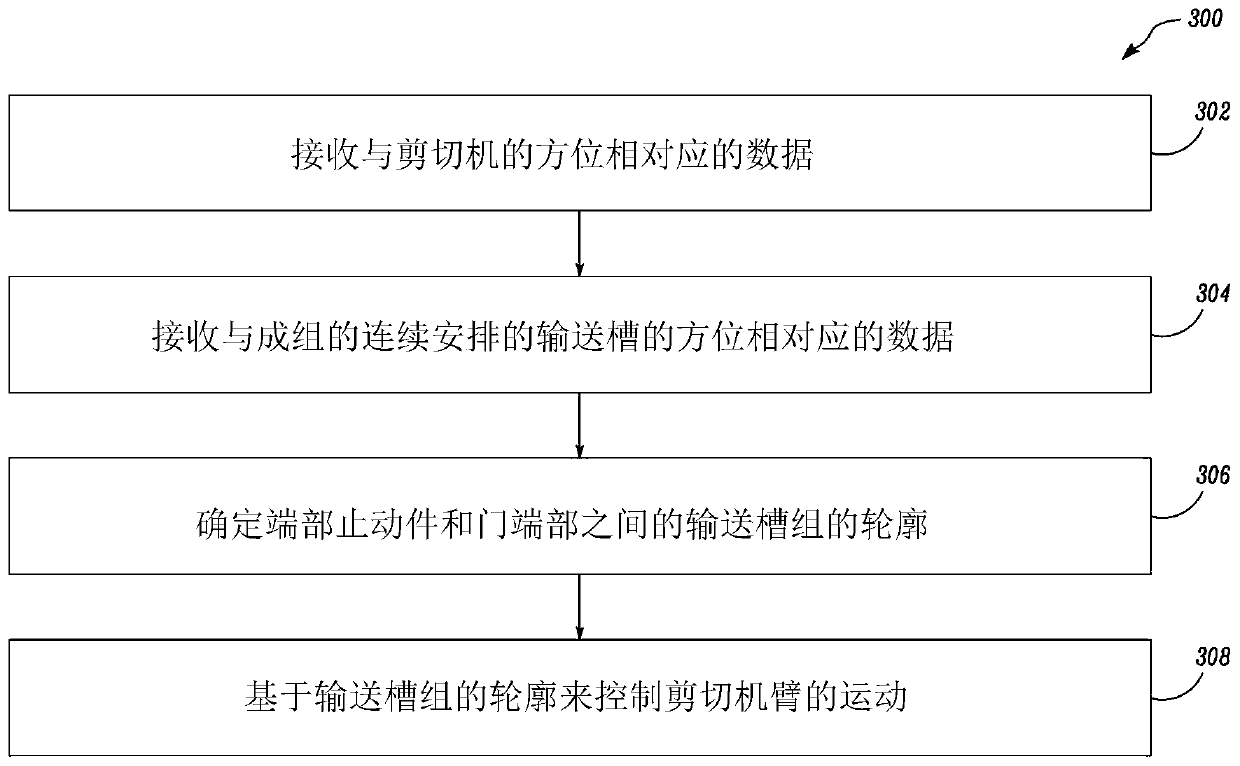

[0010] refer to figure 1 , a longwall mining machine 100 is shown. The longwall mining machine 100 may operate within an underground mine 104 to remove mineral material, such as coal, from a mining face 108 of the underground mine 104 . However, aspects of the invention may be applied to other environments, and may not be limited to those set forth in the following description and / or drawings. The longwall mining machine 100 may include a shearing system 120 having a face conveyor 124, a shearing machine 126, and a control system 128 (see figure 2 ).

[0011] see figure 1 and 2 , the face conveyor 124 may be an armored face conveyor 124 ′ and may be arranged and extended along the mining face 108 of the underground mine 104 . For example, face conveyor 124 may be located between main gate 130 and tail gate 132 of underground mine 104 (see figure 2 Exemplary notes in ) are extended between. Face conveyor 124 may include a plurality of face conveyor segments, referred t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com