Ultra-deep shield interval air shaft tunnel-ahead and main-body-following construction method

A construction method and wind shaft technology, which can be applied in the direction of sinking, tunnel, shaft lining, etc., can solve the problems of delay in construction period and failure to construct in time, and achieve the effects of saving construction period, simple construction process and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

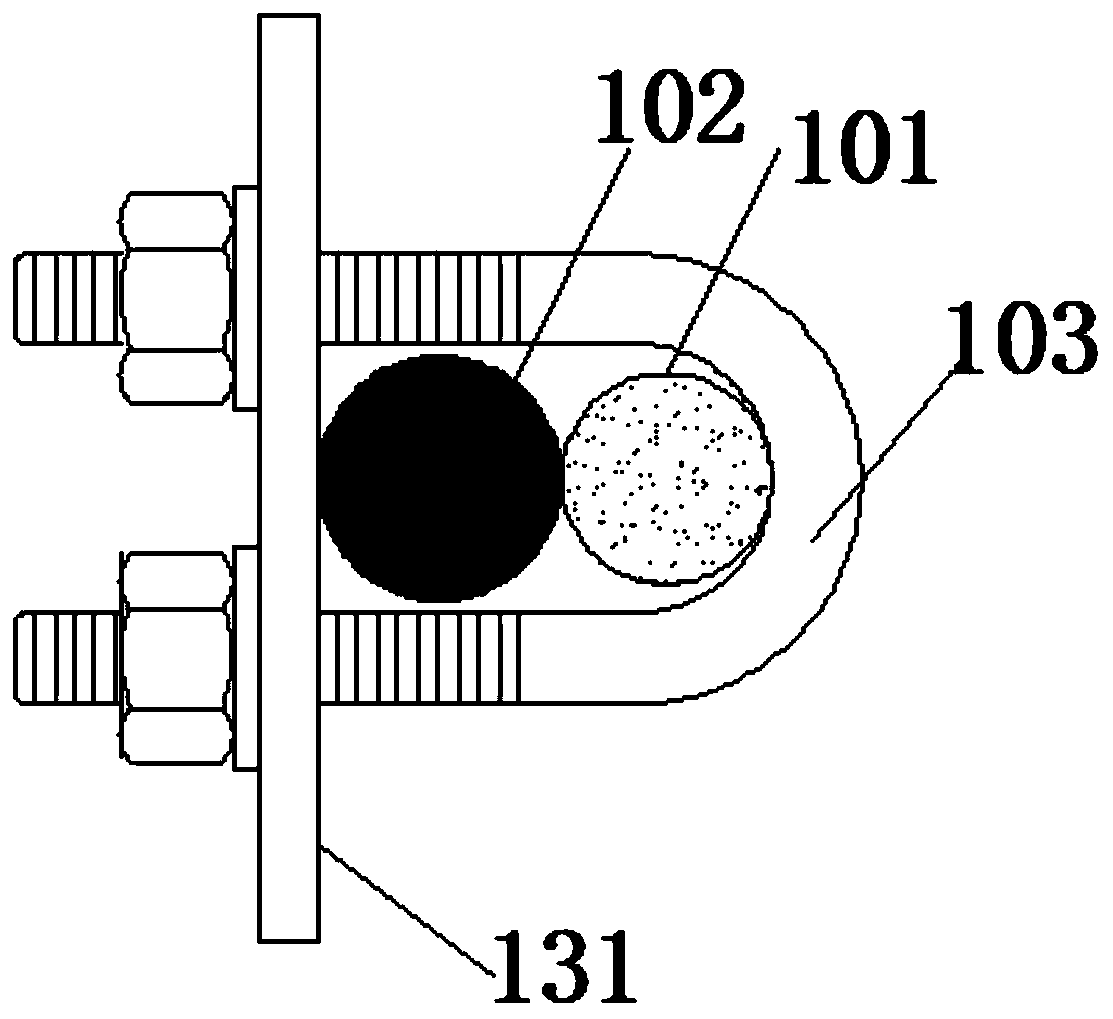

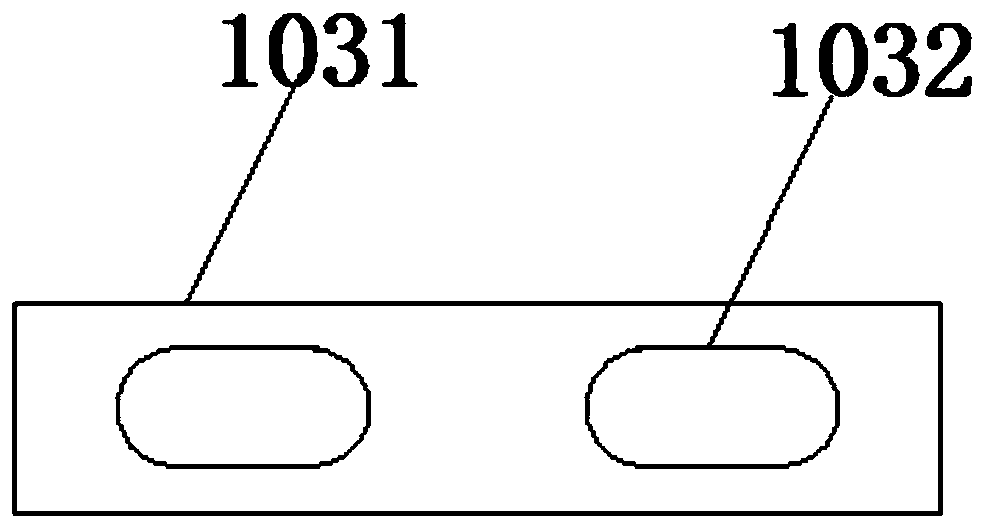

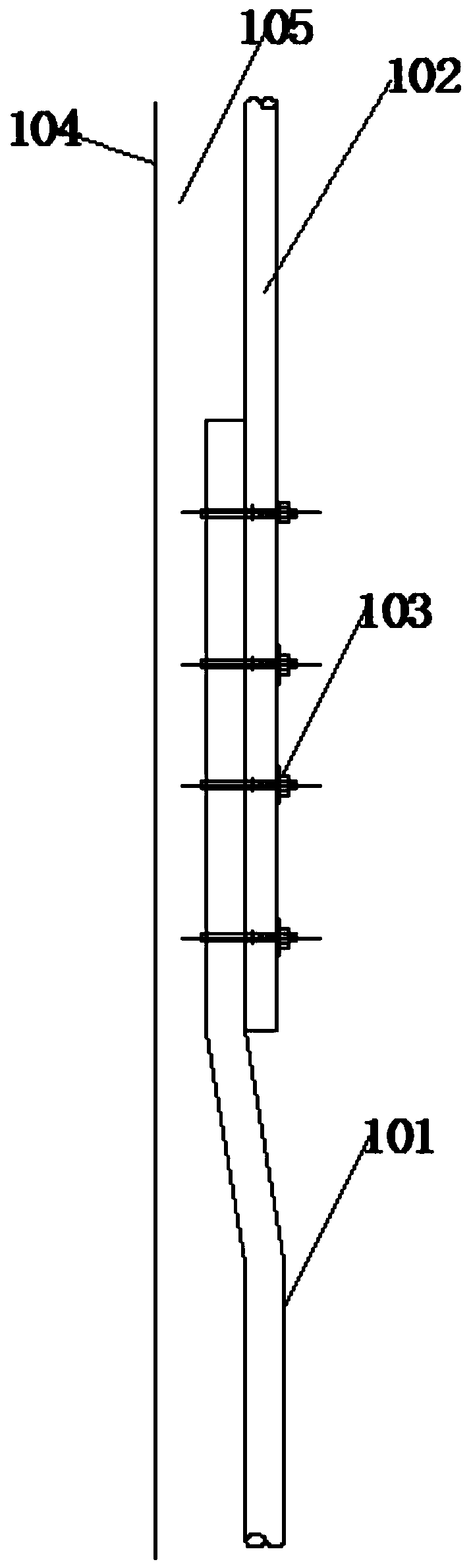

[0048] Such as Figure 1-10As shown, the present invention provides an ultra-deep shield interval air shaft first tunneling and then the main body construction method, the construction method includes the following steps:

[0049] Step S1, prepare the materials and equipment for the shield machine to pass through the air shaft and construct the air shaft connection wall 1. After the construction of the air shaft connection wall 1 is completed, use a triple tube high-pressure rotating tube at the outer joint of the air shaft connection wall 1. Spray piles 3 to reinforce and stop water, 1 pre-embedded grouting pipe at the connection wall of the air shaft at the entrance; the connection wall of the air shaft is 8m wide, the steel cage is hoisted in sections, and the connection of the steel cage is welded method, after the construction of the air well ground connection wall 1 is completed, three triple tube high-pressure jet grouting piles 3 are used to reinforce the water stop at...

Embodiment 2

[0142] Kunming Rail Transit Line 4 civil engineering standard 10 screw section air shaft is located in the middle of the screw shield section, the depth of the foundation pit is 32 meters, and the base is located in the confined water layer. Affected by the requisition and demolition, the construction of the wind shaft started late, but the shield machine in the screw shield section has already started, and the construction progress of the wind shaft affects the normal reception and re-start of the shield machine.

[0143] The shield machine in the screw bucket section started from Luosiwan Station to Dounan Station on January 15, 2017, and will reach the wind shaft on September 30, 2017 according to the normal excavation speed, and the wind shaft will start on March 6, 2017. According to the original program implementation plan, the acceptance conditions of the shield machine will be provided on November 30, 2017, which will affect the construction period of the shield machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com