Tea drying box

A technology for drying boxes and tea leaves, applied in the field of machinery, can solve the problems of slow drying, blocking hot air, and difficulty in taking out tea leaves, and achieves the effects of uniform and fast drying, and improving the speed of cloth and material reclaiming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

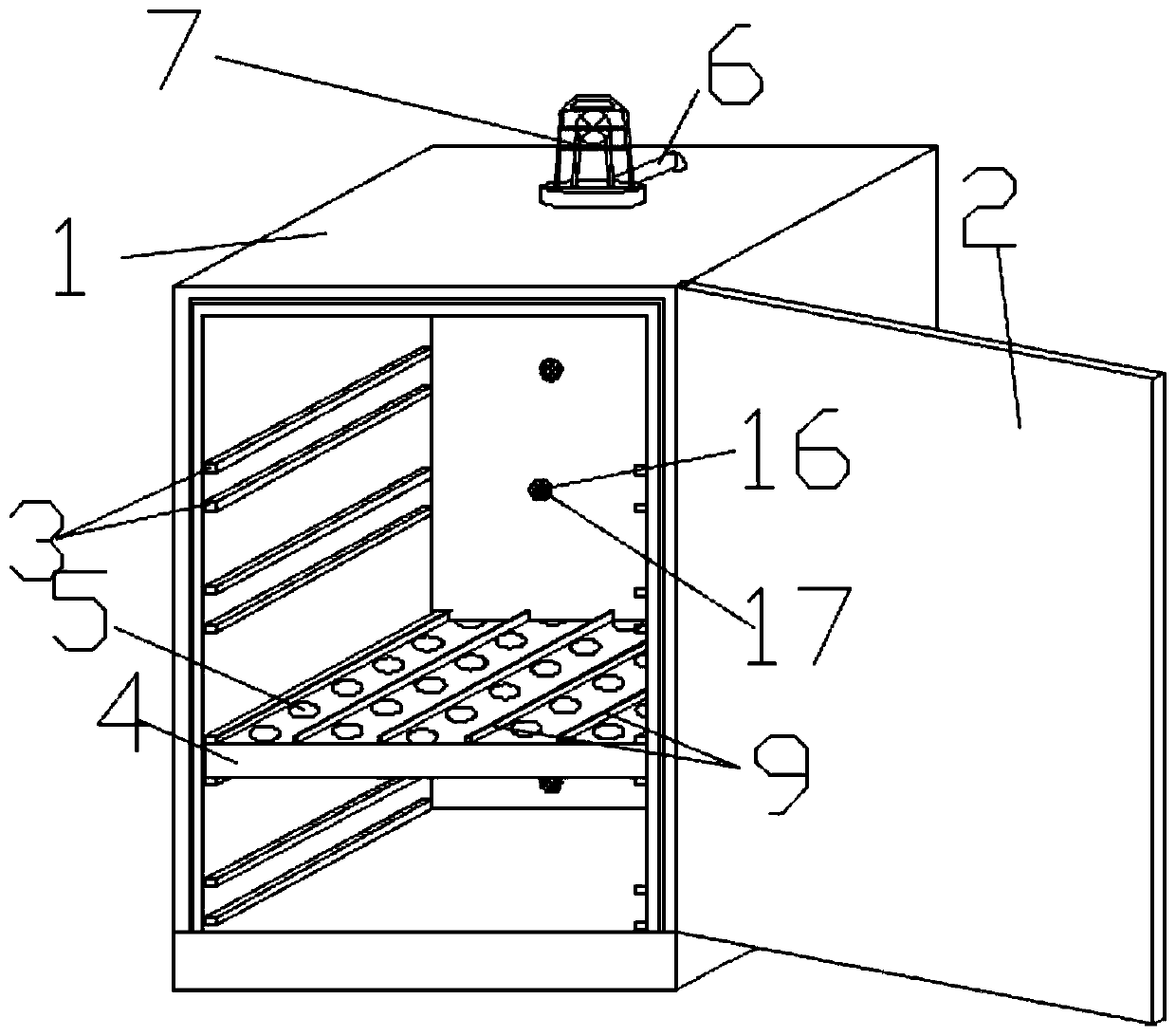

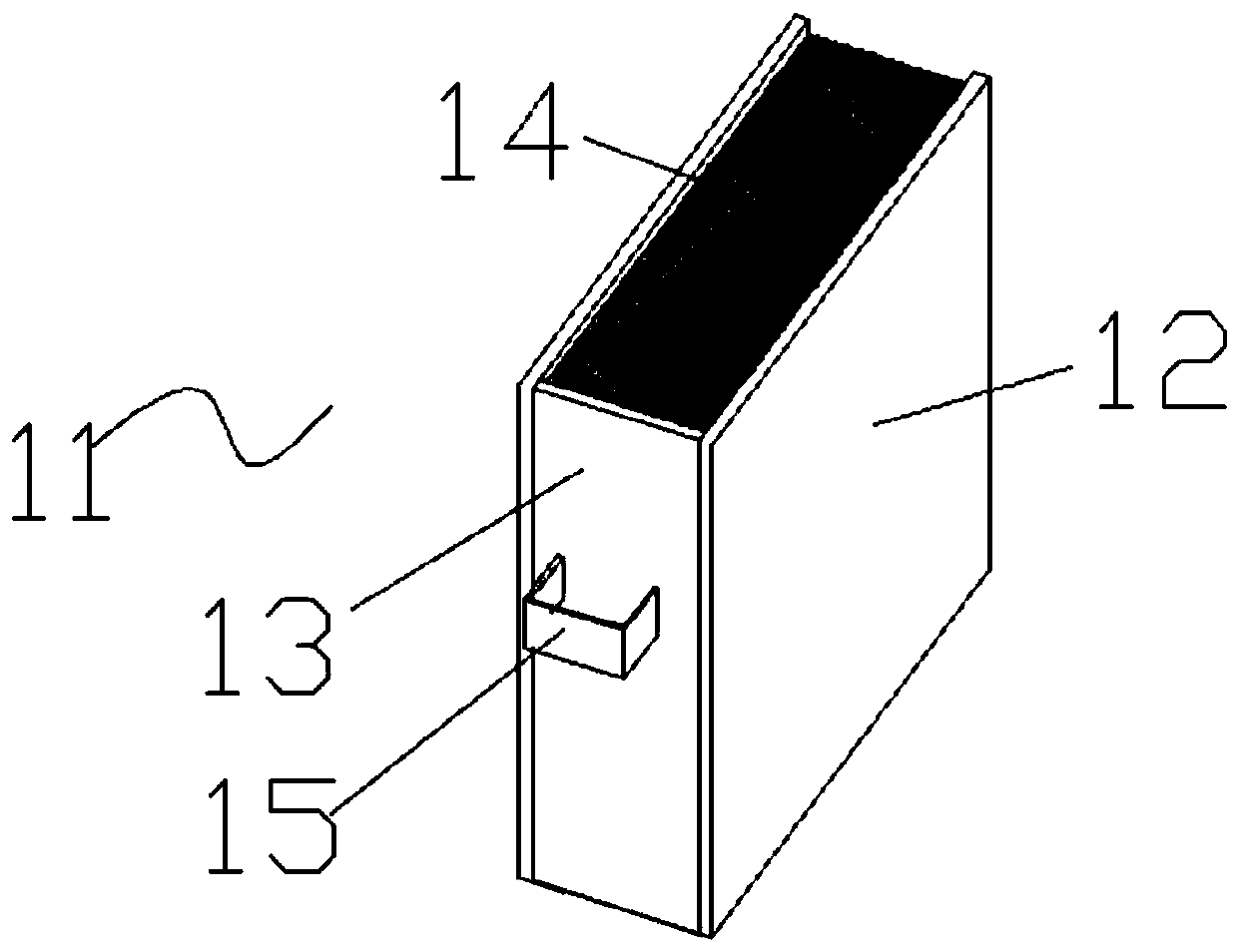

[0018] Such as figure 1 and 2 The shown tea drying box includes a housing 1, on which a door 2 is hinged, and a plurality of slide bars 3 are sequentially installed in the housing 1 from top to bottom, and slide bars 3 are slidably connected with Casing 4, casing 4 and upper and lower sides are evenly formed with air outlet 5, the rear end of casing 4 is open and is connected with hot air blower 7 by the air outlet 16 of connecting pipe 6, and filter screen 17 is installed at air outlet 16 places. Both sides of the upper and lower sides of the box body 4 are formed with a number of parallel longitudinal spacer bars 9, and drawers 11 are installed between the longitudinal spacer bars 9. The drawer 11 includes two side plates 12, and the front ends of the two side plates 12 pass through the front ends. The plates 13 are connected with each other, the front end plate 13 is fixed with a handle 15 , and a plurality of mesh plates 14 are sequentially fixed between the two side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com