A control method for balancing the amount of material on the table top of a sintering machine

A control method and sintering machine technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of production fluctuation, full warehouse, empty warehouse, etc., achieve stable blast furnace slot position, stable compaction degree, and avoid unevenness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

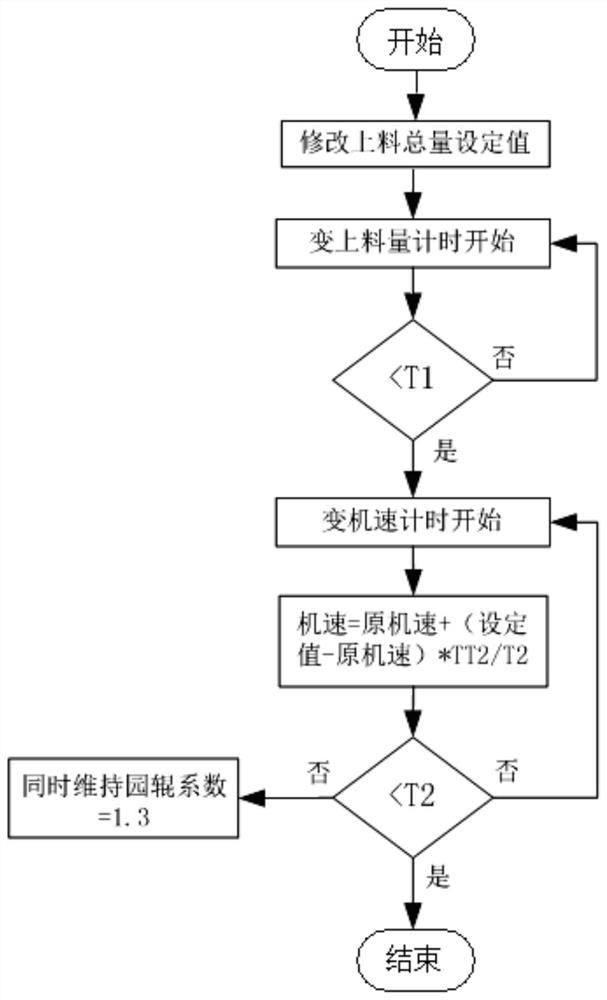

[0027] Such as figure 1 The flow block diagram of the present invention shown is a control method for maintaining a balanced amount of material on the countertop of a balanced sintering machine. The hardware equipment applied to the control method includes a sintering machine, a main exhaust fan, a main extraction motor, a main extraction frequency converter, Temperature and negative pressure measuring instruments, DCS control system, communication link and database server, etc.; software includes programming software, screen editing software and PI database, etc.

[0028] In order to solve the defects existing in the prior art and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com